Composite resin foamed particle, antistatic composite resin foamed particle and composite resin foamed particle molded body

A technology of composite resin and foamed particles, which is applied in the field of molded bodies, can solve the problems of reduced heat resistance of foamed particles, reduced fusion of foamed particles, plasticization of resin particles, etc., and achieves excellent antistatic performance and good antistatic Excellent performance and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] Hereinafter, expanded beads according to Examples will be described.

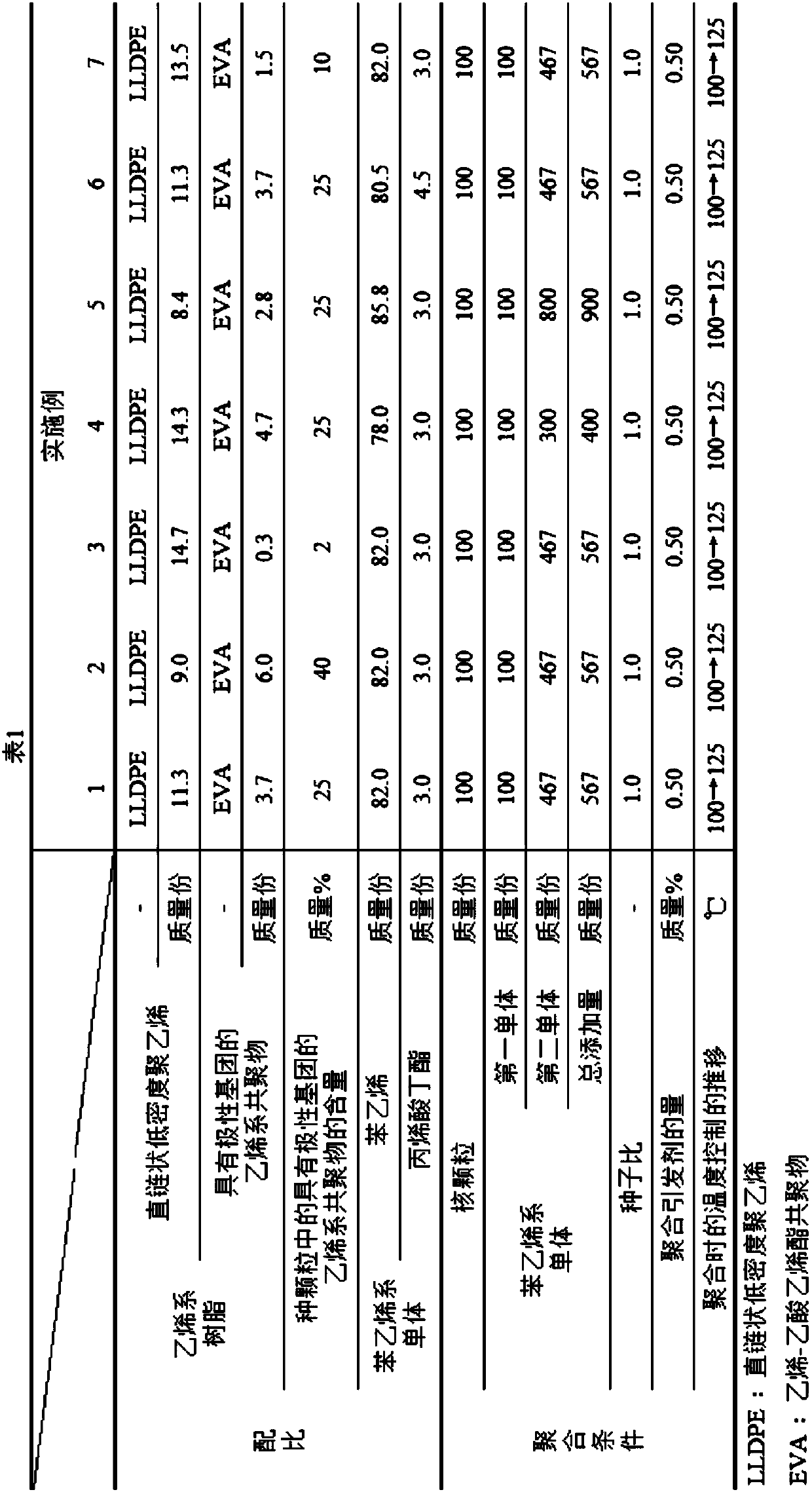

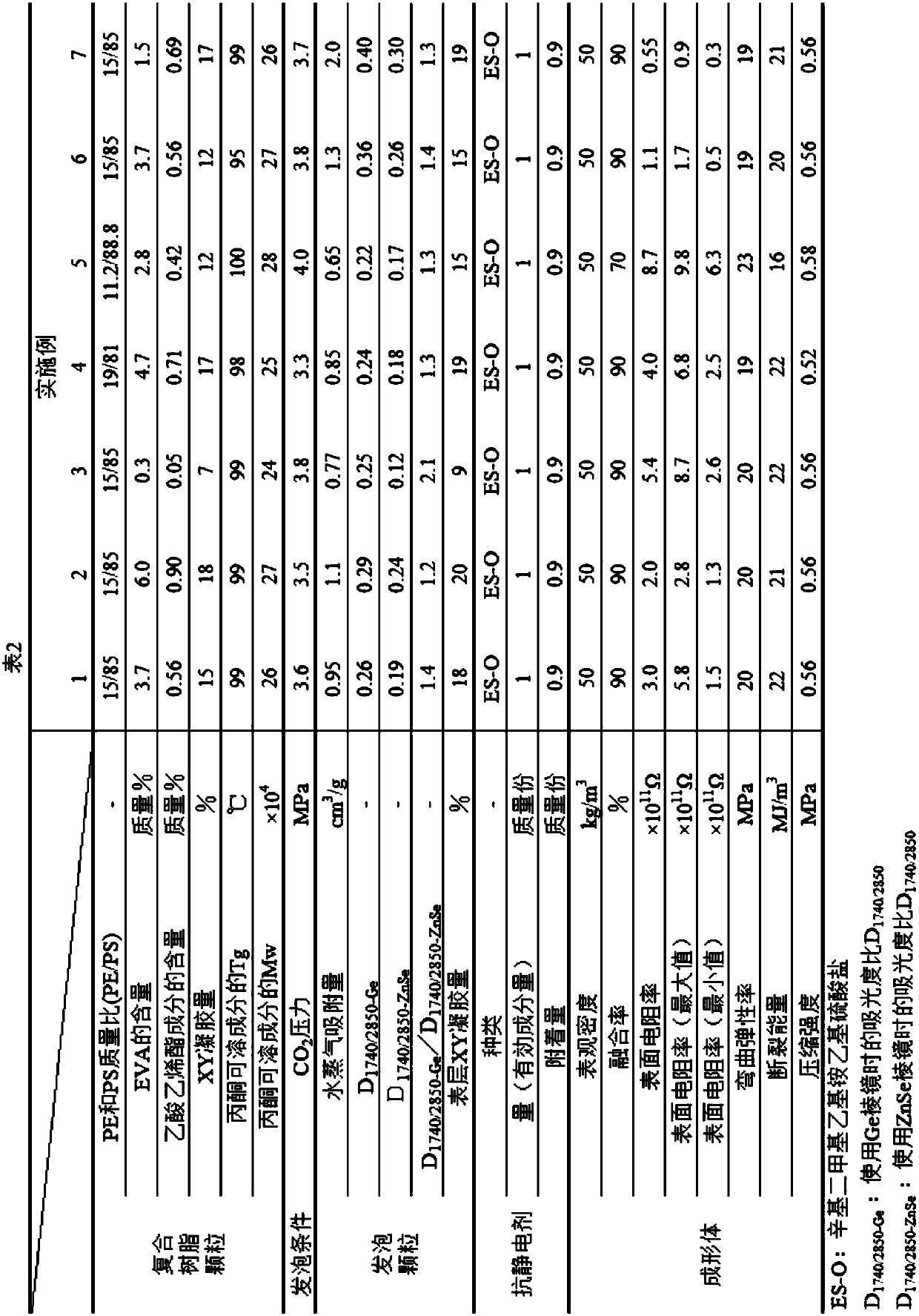

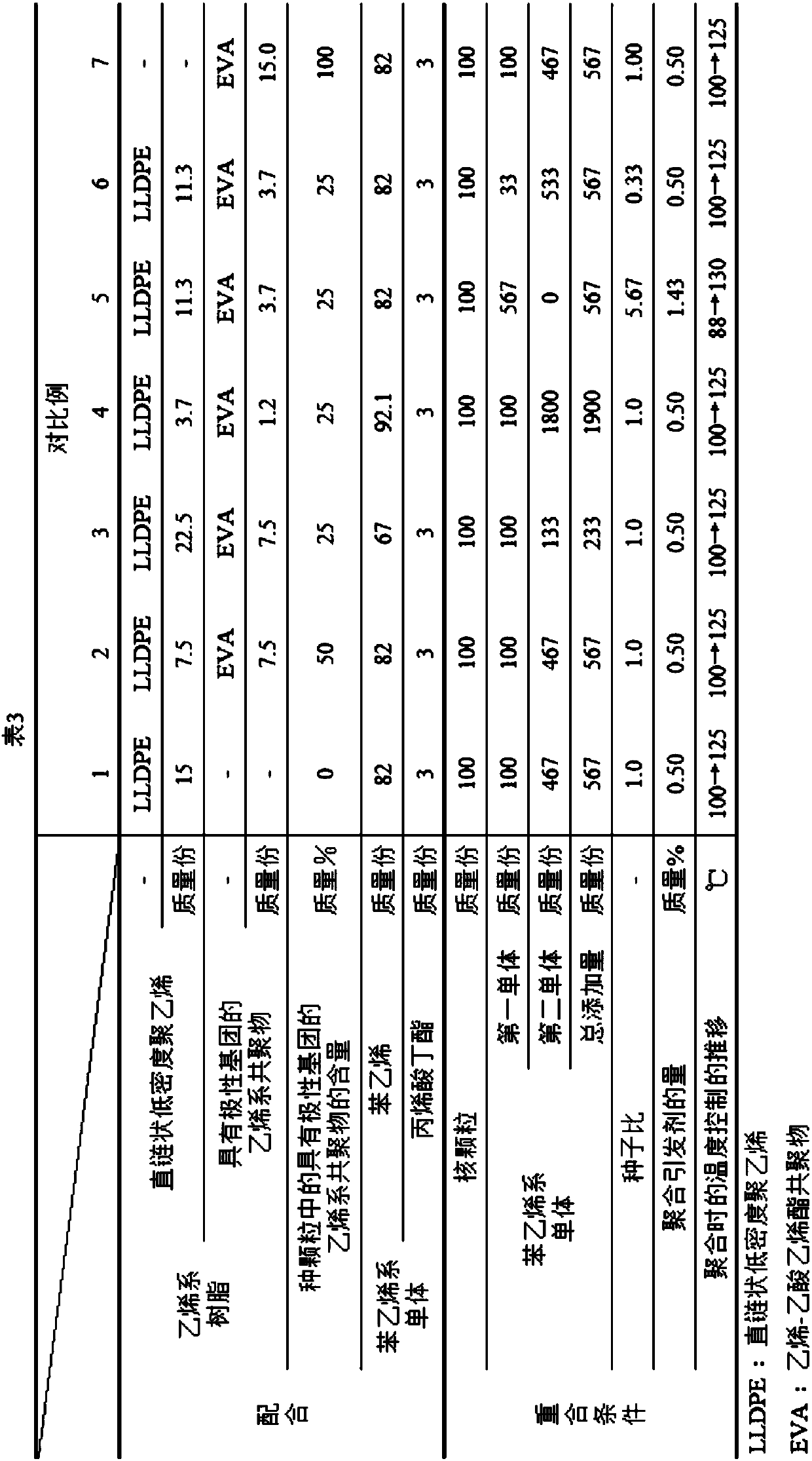

[0105] The expanded beads according to the examples use a composite resin obtained by impregnating and polymerizing a styrene-based monomer into a vinyl-based resin as a base resin. That is, the composite resin contains a styrene-based resin component obtained by polymerizing a vinyl-based resin component and a styrene-based monomer. Hereinafter, the manufacturing method of the expanded bead of this example is demonstrated. In addition, in this example, the obtained expanded beads were further subjected to in-mold molding to prepare a molded body.

[0106] (1) Preparation of nuclear particles

[0107] As vinyl resins, LLDPE (manufactured by Tosoh Corporation, trade name: Nipolon-Z HF 210K) polymerized by a metallocene polymerization catalyst, ethylene-vinyl acetate copolymer (manufactured by Asahi Kasei Chemical Co., Ltd., trade name) were prepared. Name: EF1531, the content of the vinyl acetate c...

Embodiment 2

[0154] In this example, the amount of LLDPE used in the preparation of the core particles was changed to 6 kg, the amount of EVA was changed to 4 kg, the foaming conditions during foaming (specifically, the CO in the container during foaming) 2 Pressure) was changed to the conditions shown in Table 2 described later, and expanded beads and molded bodies were prepared in the same manner as in Example 1.

Embodiment 3

[0156] In this example, the amount of LLDPE used in the preparation of the core particles was changed to 9.8 kg, the amount of EVA was changed to 0.2 kg, and the foaming conditions during foaming (specifically, the CO in the container during foaming) 2 Pressure) was changed to the conditions shown in Table 2 described later, and expanded beads and molded bodies were prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com