Antistatic sealing strip and preparation method thereof

A sealing strip and antistatic technology, which is applied in the field of antistatic sealing strips for vehicles and its preparation, can solve the problems of easy dust absorption, poor electrical conductivity, static spark fires, etc., and achieve improved dispersion performance, good antistatic performance, and mechanical properties. The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

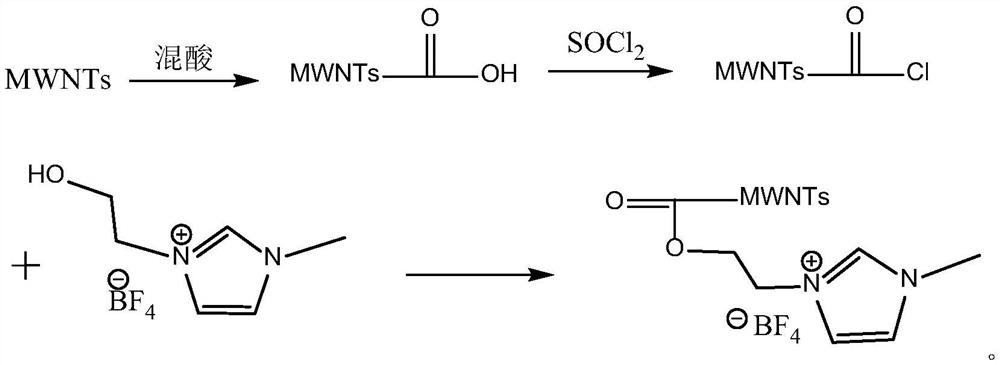

Method used

Image

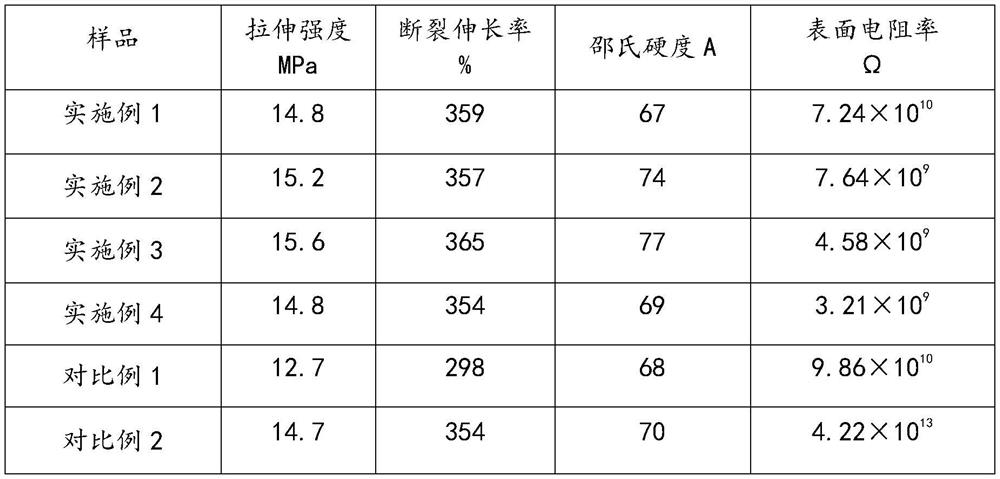

Examples

Embodiment 1

[0030] The present embodiment provides an antistatic sealing strip, which comprises 100 parts of S-1000 type PVC resin, 70 parts of polyadipate-1,2-propylene glycol ester, 18 parts of EPDM rubber, and 12 parts of calcium carbonate. 10 parts of zinc oxide, 8 parts of carbon black, 17 parts of antistatic agent, 6 parts of CZ-1 calcium zinc stabilizer, 0.3 part of zinc stearate, 1 part of diphenylsulfonyl hydrazide ether, 2 parts of zinc borate;

[0031] The preparation method of the antistatic sealing strip specifically comprises the following steps:

[0032] (1) Surface modification of inorganic fillers: 12g of inorganic fillers calcium carbonate, 10g of zinc oxide, 2g of zinc borate and 3g of polyvinyl ester were weighed according to the mass ratio and added to the kneader for kneading for 40min, then heat treated at 90°C for 2h , to obtain a filler system with ester-based surface modification;

[0033] (2) The surface-modified filler system, PVC resin 100g, polyadipate-1,2-p...

Embodiment 2

[0037] The present embodiment provides an antistatic sealing strip, which comprises 100 parts of S-1000 type PVC resin, 80 parts of polyadipate-1,2-propylene glycol ester, 27 parts of EPDM rubber, and 15 parts of calcium carbonate. 12 parts of zinc oxide, 13 parts of carbon black, 20 parts of antistatic agent, 7 parts of CZ-1 calcium zinc stabilizer, 0.8 parts of zinc stearate, 1 part of diphenylsulfonyl hydrazide ether, 3 parts of zinc borate;

[0038] The preparation method of the antistatic sealing strip is the same as in Example 1.

Embodiment 3

[0040] The present embodiment provides an antistatic sealing strip, which comprises 100 parts of S-1000 type PVC resin, 75 parts of polyethylene adipate, 24 parts of EPDM rubber, 15 parts of calcium carbonate, oxidized 12 parts of zinc, 13 parts of carbon black, 20 parts of antistatic agent, 7 parts of CZ-1 calcium zinc stabilizer, 0.8 parts of zinc stearate, 1 part of diphenylsulfonyl hydrazide ether, 3 parts of aluminum oxide;

[0041] The preparation method of the antistatic sealing strip is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com