Long-lasting antistatic polyester random copolymer and preparation method and use thereof

A random copolymer, antistatic technology, applied in polyester coatings, coatings, etc., can solve the problems affecting processing and use performance, lack of polar groups, poor antistatic performance, etc., to achieve excellent antistatic performance, Improve antistatic ability and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An embodiment of the long-acting antistatic polyester random copolymer of the present invention, the preparation method of the long-acting antistatic polyester random copolymer comprises the following steps: in a dry 1000mL four-necked flask, add 287g of terephthalic acid, 32g of adipic acid, 50g of neopentyl glycol, 89mL of ethylene glycol, and 130g of polypropylene glycol, stirred and purged with nitrogen for 15 minutes to remove oxygen. Add 0.413mL tetrabutyl titanate and mix well. Stir slowly and heat up, and control the material at 235°C for 4 hours; cool down to below 200°C, add 2.5g of hydroquinone and 0.962mL of tetrabutyl titanate, keep the reaction temperature at 220°C, pump the vacuum reaction for 3 hours, and then raise the temperature Vacuumize and react at 225° C. with an oil pump for 2 hours, and discharge while hot to obtain the long-acting antistatic polyester random copolymer.

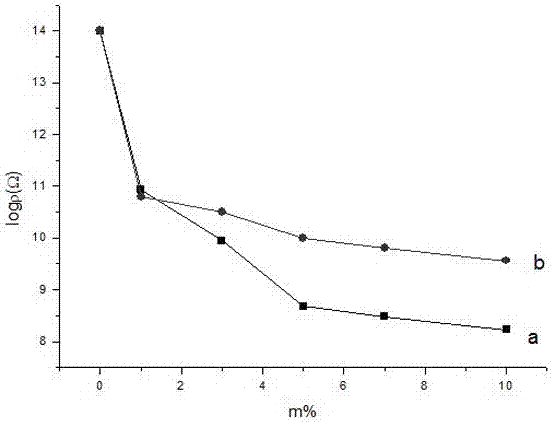

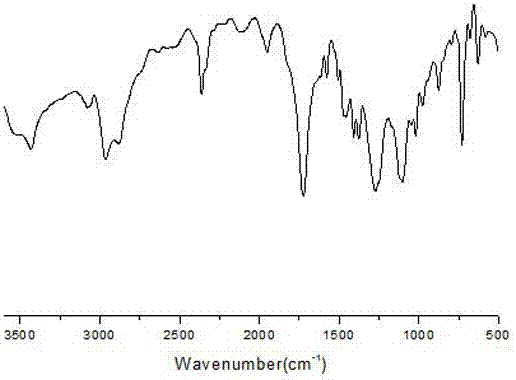

[0035] The obtained long-acting antistatic polyester random copolymer has...

Embodiment 2

[0040] An embodiment of the long-acting antistatic polyester random copolymer of the present invention, the preparation method of the long-acting antistatic polyester random copolymer comprises the following steps: in a dry 1000mL four-necked flask, add 269g of terephthalic acid, 32g of adipic acid, 30g of polyethylene glycol, 50g of neopentyl glycol, 189mL of ethylene glycol, and 30g of polypropylene glycol, stirred and purged with nitrogen for 15 minutes to remove oxygen. Add 0.413mL tetrabutyl titanate and mix well. Stir slowly and heat up, and control the material at 235°C for 4 hours; cool down to below 200°C, add 2.5g of hydroquinone and 0.962mL of tetrabutyl titanate, keep the reaction temperature at 220°C, pump the vacuum reaction for 3 hours, and then raise the temperature React at 225° C. with an oil pump for 2 hours, and discharge while hot to obtain the long-acting antistatic polyester random copolymer.

[0041] The obtained long-acting antistatic polyester random...

Embodiment 3

[0045] An embodiment of the long-acting antistatic polyester random copolymer of the present invention, the preparation method of the long-acting antistatic polyester random copolymer comprises the following steps: in a dry 1000mL four-necked flask, add 300g of terephthalic acid, 30g of succinic acid, 20g of glycerol, and 220mL of ethylene glycol were stirred and nitrogen gas was passed for 15 minutes to remove oxygen. Add 0.725mL tetrabutyl titanate and mix well. Stir and heat up slowly, and control the material at 240°C for 4 hours; cool down to below 200°C, add 3g of triphenyl phosphite and 0.615mL of tetrabutyl titanate, keep the reaction temperature at 230°C for 3 hours by pumping a vacuum pump, then raise the temperature React at 235° C. with an oil pump for 1.5 hours, and discharge while hot to obtain the long-acting antistatic polyester random copolymer.

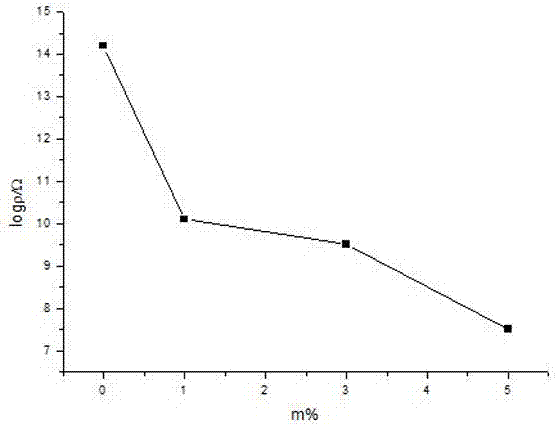

[0046] The obtained long-acting antistatic polyester random copolymer has a molecular weight of 8000 g / mol, a hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com