Water-resistant wear-resistant antistatic polyester film and preparation method thereof

A polyester film and antistatic technology, applied in the field of polyester film, can solve the problems that the comprehensive performance of antistatic polyester cannot meet the actual needs, the loss of antistatic performance of antistatic polyester, etc., and achieve excellent antistatic performance and excellent moisture resistance. Durable and durable antistatic, mesh-stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

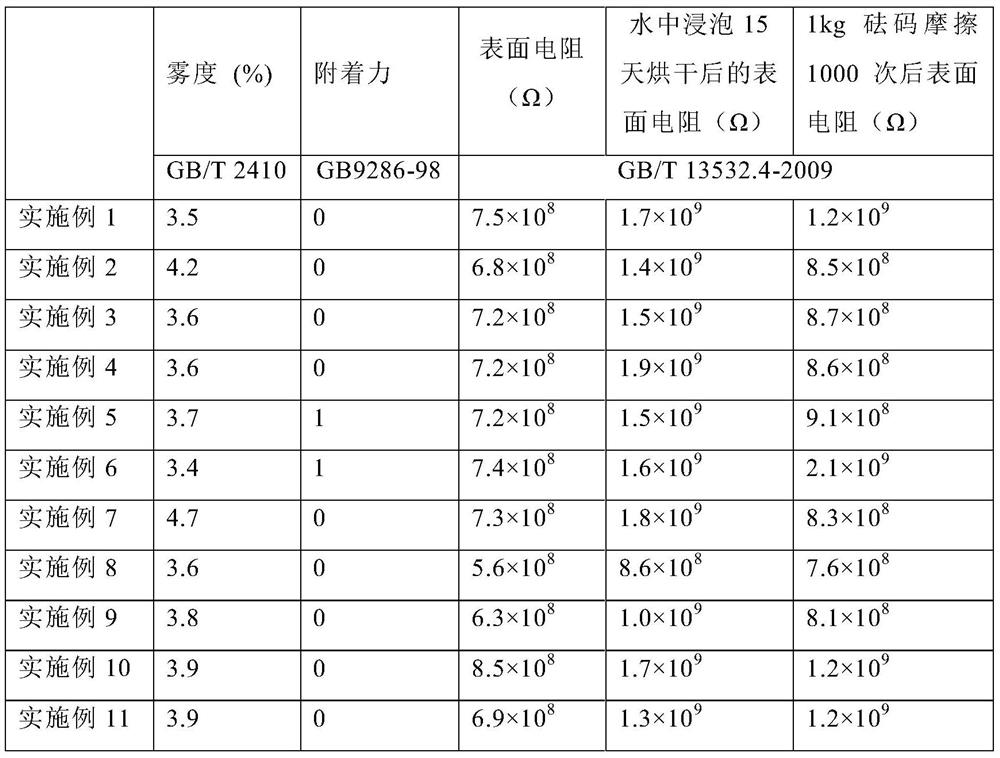

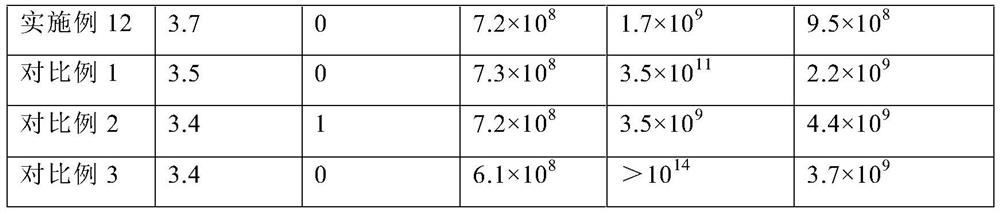

Examples

preparation example 1

[0047] Weigh 15 parts of mixed monomer, 5 parts of DSM 9720S, 2 parts of poly-3,4-ethylenedioxythiophene, 5 parts of OP-10, 1 part of BYK333, 1 part of polyvinyl alcohol, 0.5 parts of 2-hydroxy -2-Methyl-1-phenylacetone is dropped into 300 parts of ethanol aqueous solution (60% of ethanol volume concentration), stirring makes it mix uniformly to obtain antistatic material solution, is used for the antistatic coating liquid of follow-up polyester film, Wherein the mixed monomer is 2-acrylamido-2-methylpropanesulfonic acid, 2-acrylamidotetradecylsulfonic acid, 2-hydroxyethyl acrylate and polyethylene glycol diacrylate according to the mass ratio of 20:5:10:2.

preparation example 2

[0049] Weigh 25 parts of mixed monomer, 8 parts of DSM 9720S, 5 parts of poly(3,4-ethylenedioxythiophene), 10 parts of AEO-3, 1 part of BYK333, 1 part of polyvinyl alcohol, 1 part of 2-hydroxy -2-Methyl-1-phenylacetone is put into 300 parts of ethanol aqueous solution (ethanol volume concentration 60%), stirred to make it mix uniformly to obtain antistatic material solution, wherein the mixed monomer is 2-acrylamide-2- Methylpropanesulfonic acid, 4-(6-(acryloyloxy)hexyloxy)benzoic acid, 2-hydroxyethyl acrylate and polyethylene glycol diacrylate are in a mass ratio of 20:8:15:4 .

preparation example 3

[0051] Weigh 20 parts of mixed monomers, 6 parts of DSM 9720S, 3.5 parts of poly(3,4-ethylenedioxythiophene), 8 parts of AEO-3, 1 part of BYK333, 1 part of polyvinyl alcohol, 0.6 parts of 2-hydroxy -2-Methyl-1-phenylacetone is put into 300 parts of ethanol aqueous solution (ethanol volume concentration 60%), stirred to make it mix uniformly to obtain antistatic material solution, wherein the mixed monomer is 2-acrylamide-2- Methylpropanesulfonic acid, 4-(6-(acryloyloxy)hexyloxy)benzoic acid, 2-hydroxyethyl acrylate and polyethylene glycol diacrylate are in a mass ratio of 20:6:12:3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com