Anti-adhesion antistatic polyester film

A polyester film and anti-adhesion technology, which is applied in polyester coatings, polyurea/polyurethane coatings, conductive coatings, etc., can solve problems such as incomplete curing, shortened drying time of ink, and easy adhesion between the ink layer and the antistatic layer , to achieve excellent effect and excellent antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

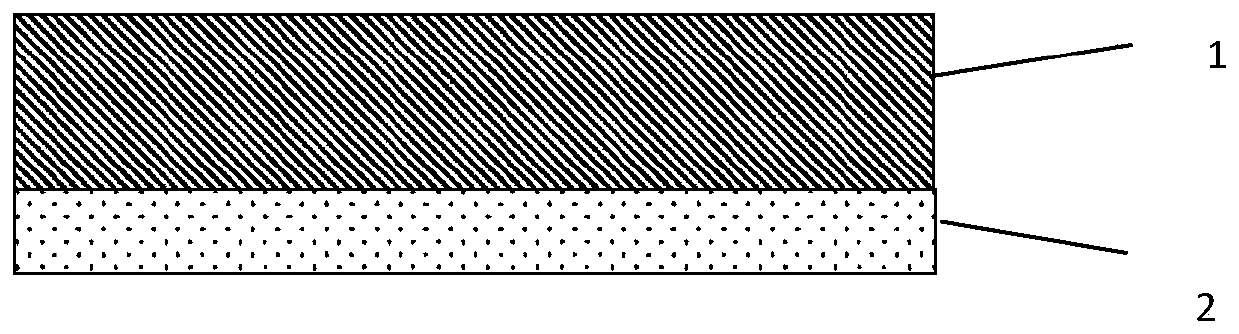

Image

Examples

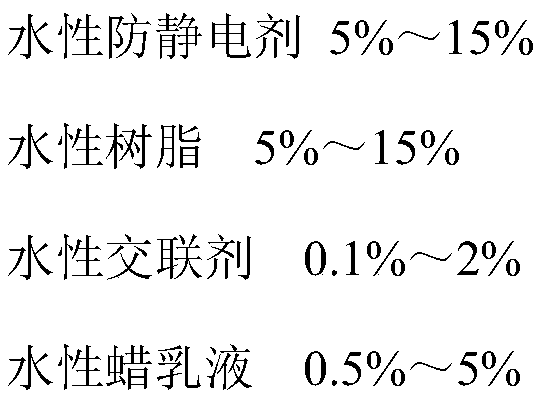

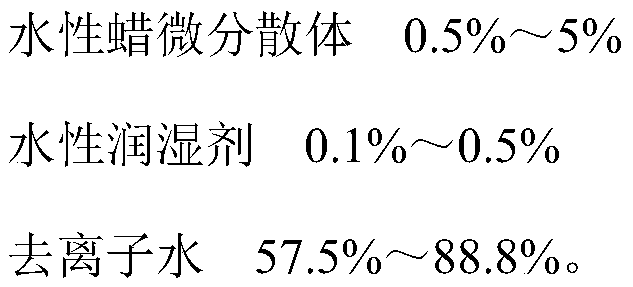

Embodiment 1

[0029] Get water-based carbon nanotube dispersion (the trade mark is CNTS-016, Suzhou Carbonfeng Graphene Technology Co., Ltd., the mass ratio of carbon nanotubes in the water-based carbon nanotube dispersion is 1%) 5g, water-based polyurethane (the trade mark is Huayue , Hefei Huayue New Material Technology Co., Ltd.) 5g, melamine crosslinking agent (the brand is LF-8500, Lin’an Funeng Resin Co., Ltd.) 0.1g, wax emulsion (the brand is L-01, Guangzhou Huimai Industrial Co., Ltd. company) 0.5g, wax microdispersion (brand 010101, Nanjing Baiju Technology Co., Ltd.) 0.5g, water-based wetting agent (brand is TFE-2, Sangda Chemical Co., Ltd., polyoxyethylene polyoxypropylene block copolymerization substance) 0.1g, deionized water 88.8g, the above-mentioned substances were mixed and dispersed evenly with a high-shear emulsifier to make an anti-blocking and antistatic coating liquid. Then the prepared anti-blocking and antistatic coating solution is coated on the surface of polyester...

Embodiment 2

[0031] Get water-based carbon nanotube dispersion (the trade mark is CNTS-016, Suzhou Carbonfeng Graphene Technology Co., Ltd., the mass ratio of carbon nanotubes in the water-based carbon nanotube dispersion is 1%) 10g, water-based polyester (the trade mark is HT -350, Hefei Hengtian New Material Technology Co., Ltd.) 10g, aziridine crosslinking agent (the brand is SAC-100, Shanghai Youen Chemical Co., Ltd.) 1g, wax emulsion (the brand is WE6, Huisheng Trading Co., Ltd.) 2g 1. Wax microdispersion (the brand is CERFOBOL R75, Lvyuan Baizhu Chemical Co., Ltd.) 2.5g, water-based wetting agent (the brand is EH-9 / 6 / 3, Shenzhen Rongchang Technology Co., Ltd., polyoxyethylene fatty alcohol ether) 0.3g, 74.2g of deionized water, after mixing the above-mentioned substances, disperse evenly with a high-shear emulsifier to make an anti-blocking and antistatic coating liquid. Then the prepared anti-blocking and antistatic coating solution is coated on the surface of the polyester film by ...

Embodiment 3

[0033] Get water-based carbon nanotube dispersion (the trade mark is CNTS-016, Suzhou Carbonfeng Graphene Technology Co., Ltd., the mass ratio of carbon nanotubes in the water-based carbon nanotube dispersion is 1%) 15g, water-based acrylate (the trade mark is AA -8662S, Suzhou Qingtian New Material Co., Ltd.) 15g, oxazoline crosslinking agent (brand XH-540, Dongwan Xuyihua Chemical Co., Ltd.) 2g, wax emulsion (brand OE-6102, Uso Chemical Technology Co., Ltd. Co., Ltd.) 5g, wax microdispersion (the brand is XH-3200, Xinghong Chemical Materials Co., Ltd.) 5g, water-based wetting agent (the brand is PE-100, Guangzhou Hengyu Chemical Co., Ltd., polyoxyethylene alkylphenol ether ) 0.5g, deionized water 57.5g, the above-mentioned substances are mixed and dispersed evenly with a high-shear emulsifier to make an anti-blocking and antistatic coating liquid. Then the prepared anti-blocking and antistatic coating solution is coated on the surface of the polyester film by gravure coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com