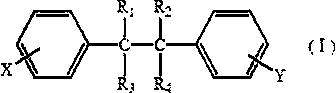

Flame-retardant polyolefin composition and preparation method thereof

A composition and polyolefin technology, applied in the field of polymers, can solve the problems of reducing material transparency, poor physical properties, environmental pollution and health, and achieve excellent surface gloss and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

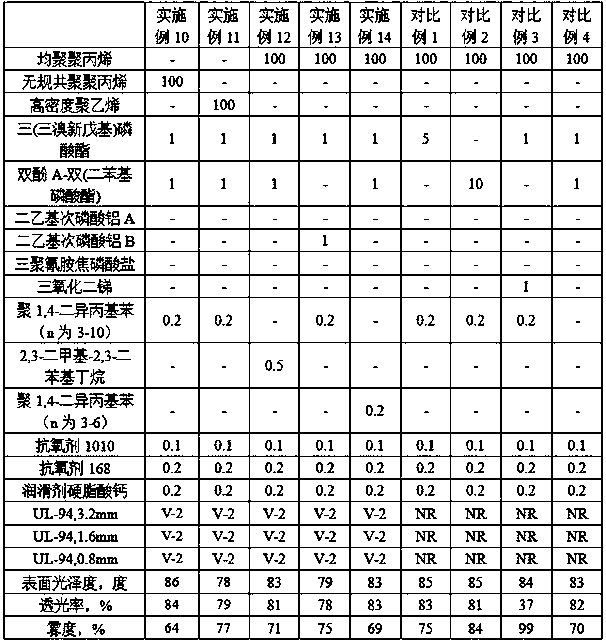

Examples

Embodiment

[0056] The preparation method of embodiment, comparative example flame retardant polyolefin composition:

[0057] The polyolefin resin, tris(tribromoneopentyl) phosphate, phosphorus flame retardant, flame retardant synergist, antioxidant, processing aid are weighed in proportion, mixed uniformly by a high-speed mixer, and then passed through a double The screw extruder melts and extrudes at 200° C., pelletizes, and obtains a flame-retardant polyolefin composition after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com