Preservative solution use for copper and copper alloy surface, preparation method and application

A technology of copper alloy and anti-corrosion liquid, applied in anti-corrosion coatings, coatings, etc., can solve the problems of reducing the heat resistance of coatings, and achieve good scratch resistance, high cross-linking density, and improved heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

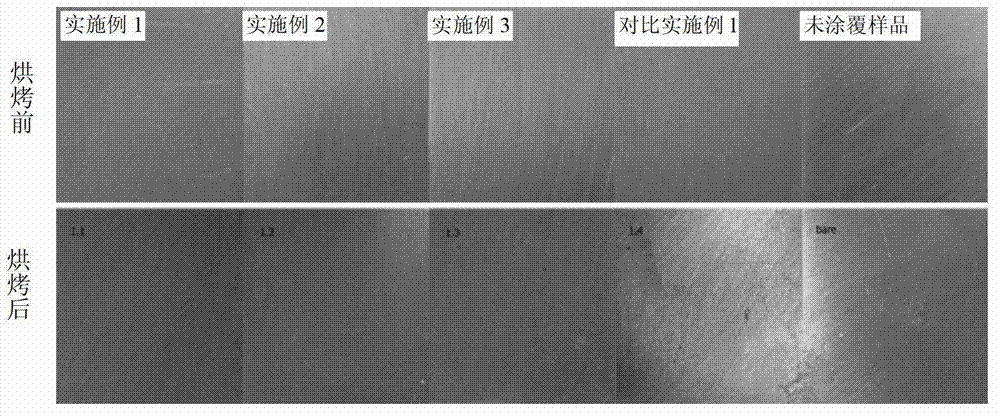

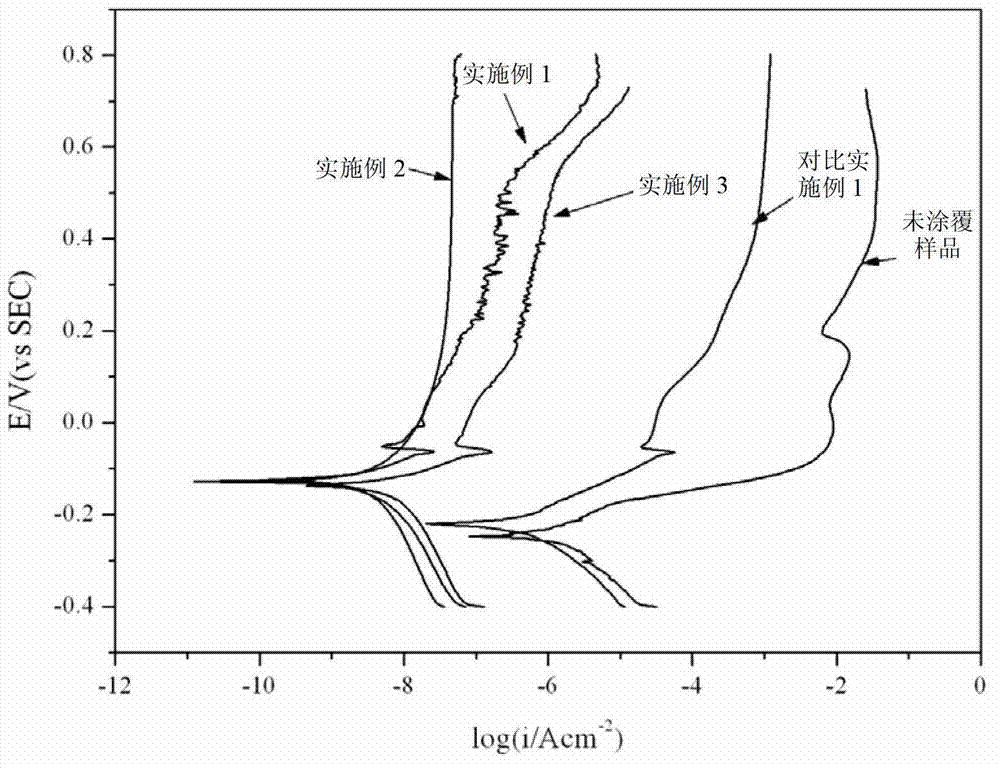

[0038]In this example, the anti-corrosion liquid used on the surface of copper and copper alloys is produced by the reaction of mercaptopropyltrimethoxysilane and tetraethoxysilane in ethanol solvent under the condition of hydrolysis catalyst solution: formic acid aqueous solution with pH=3 The hydrolyzate; wherein, the mass ratio of mercaptopropyltrimethoxysilane to tetraethoxysilane is 588:208.

[0039] The preparation process of above-mentioned preservative liquid is as follows:

[0040] Add 588g of mercaptopropyltrimethoxysilane, 208g of tetraethoxysilane, and 1000g of ethanol to a flask equipped with a mechanical stirrer, and add 540g of hydrolysis catalyst solution under stirring conditions: formic acid aqueous solution with pH=3 to make the reaction system A hydrolysis reaction occurred in the reaction, after the reaction was completed, it was stirred at room temperature for 5 h, and a clear solution was obtained after standing still.

Embodiment 2

[0042] In the present embodiment, the anticorrosion solution used for copper and copper alloy surfaces is basically the same as the anticorrosion solution in Example 1, the difference is: the quality of mercaptopropyltrimethoxysilane and tetraethoxysilane in the present embodiment The ratio is 392:208.

[0043] The preparation method of the above-mentioned anticorrosion liquid in the present embodiment is basically the same as the preparation method of the anticorrosion liquid in Example 1, the difference is: 392g mercaptopropyltrimethoxysilane, 208g tetraethoxysilane and 1000g ethanol are added Carry out the hydrolysis reaction in a flask equipped with a mechanical stirrer.

Embodiment 3

[0045] In the present embodiment, the anticorrosion solution used for copper and copper alloy surfaces is basically the same as the anticorrosion solution in Example 1, the difference is: the quality of mercaptopropyltrimethoxysilane and tetraethoxysilane in the present embodiment The ratio is 196:208.

[0046] The preparation method of the above-mentioned anticorrosion liquid in the present embodiment is basically the same as the preparation method of the anticorrosion liquid in Example 1, the difference is: 196g mercaptopropyltrimethoxysilane, 208g tetraethoxysilane and 1000g ethanol are added Carry out the hydrolysis reaction in a flask equipped with a mechanical stirrer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com