Water-based two-component floor paint and preparation method thereof

A water-based two-component, floor paint technology, applied in the field of coatings, can solve the problems of single-component performance that cannot meet the actual application requirements, human health and environmental protection, and difficult to accept by construction personnel, etc., to achieve excellent scratch resistance, Excellent construction performance, safety and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned water-based two-component floor paint with simple process, low cost, easy operation and control. This preparation method comprises the steps:

[0041] S01. Weigh each component according to the formula: weigh each component according to the formula of the above-mentioned water-based two-component floor paint;

[0042] S02. Prepare the first mixed solution: add the leveling agent, surfactant, and other anti-scratch agents weighed in step S01 into the aqueous polyacrylate emulsion under stirring conditions, and prepare the first mixed solution;

[0043] S03. Prepare the second mixed solution: add the defoamer weighed in step S01 to the first mixed solution prepared in step S02 under stirring conditions to prepare the second mixed solution;

[0044] S04. Prepare the third mixed solution: add the film-forming aid weighed in step S01 to the second mixed solutio...

Embodiment 1

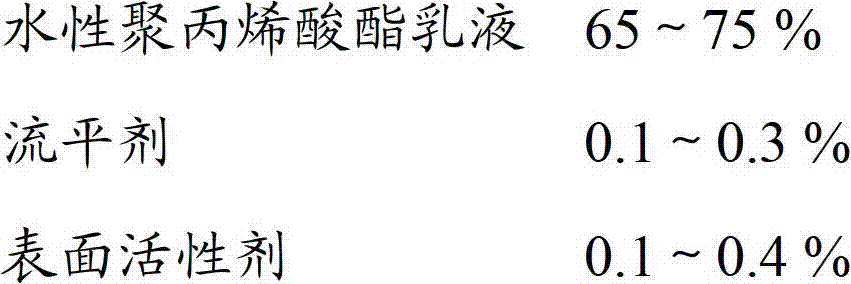

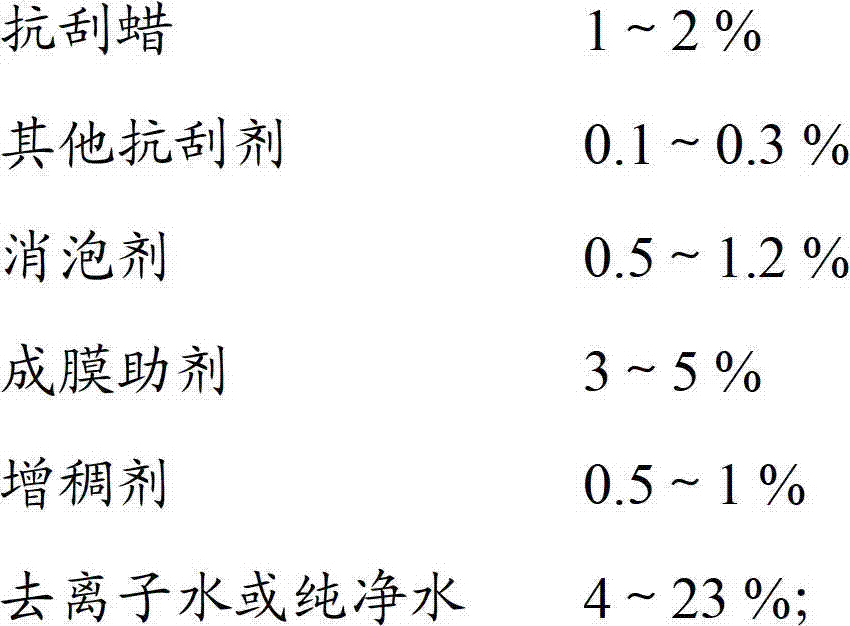

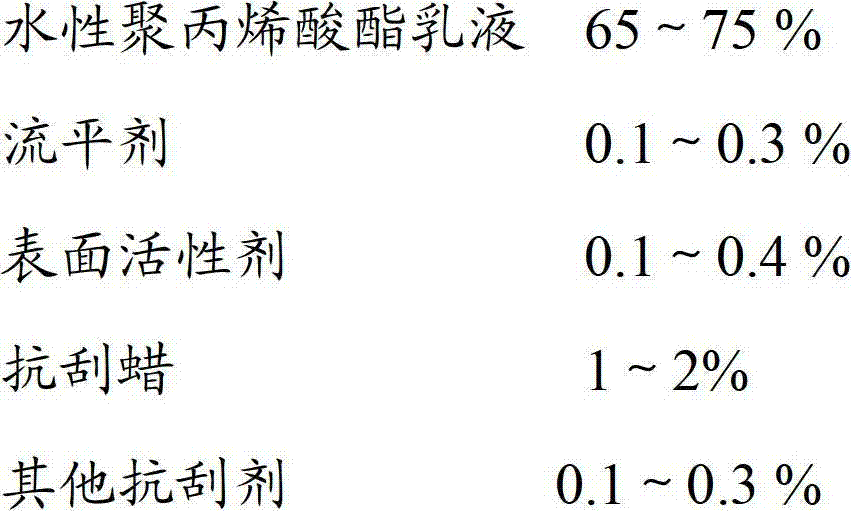

[0055] A kind of water-based two-component floor paint and preparation method thereof:

[0056] S11. Weigh each component according to the formula of water-based two-component floor paint in the following table 1; wherein, the water-based polyacrylate emulsion in component A does not contain hydroxyl but contains carboxyl and the solid content is 65-75% wt%, its mass part is 65, the leveling agent is 0.1 mass part of BYK 337, the surfactant is 0.1 mass part of BYK 349, the other anti-scratch agent is 0.1 mass part of BYK 301, and the defoamer is 0.5 mass part BYK 028, the film-forming aid is 3 parts by mass of DPM, the thickener is 0.5 parts by mass of RM-8W; component B is water-dispersed polydiisocyanate with a solid content of 65%-75%, and its mass parts Makes 8 servings.

[0057] S12. Add the leveling agent, surfactant, and other anti-scratch agents weighed in step S11 into the aqueous polyacrylate emulsion under stirring to prepare the first mixed solution; wherein the s...

Embodiment 2

[0064] A kind of water-based two-component floor paint and preparation method thereof:

[0065] S21. Weigh each component according to the formula of the water-based two-component floor paint in the following table 1; wherein, the water-based polyacrylate emulsion in the first component does not contain hydroxyl but contains carboxyl and the solid content is 65-75% wt%, its mass part is 65, the leveling agent is 0.1 mass part of BYK 337, the surfactant is 0.1 mass part of BYK 349, the other anti-scratch agent is 0.1 mass part of BYK 301, and the defoamer is 0.5 mass part For BYK 028, the film-forming aid is 3 parts by mass of DPM, the anti-scratch wax is 1 part by mass, and the thickener is 0.5 parts by mass of RM-8W; component B is a water dispersion with a solid content of 65%-75%. Type polydiisocyanate, its mass parts are 8;

[0066] S22. Add the leveling agent, surfactant, and other anti-scratch agents weighed in step S21 into the aqueous polyacrylate emulsion under stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com