UV (ultraviolet)-blocking and antifouling coating composition, hard coating film and preparation methods

A technology of composition and hardened film, which is applied in the direction of antifouling/underwater coatings, coatings, polyester coatings, etc., to achieve the effects of hydrophobic and oleophobic antifouling performance, scratch resistance, and excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

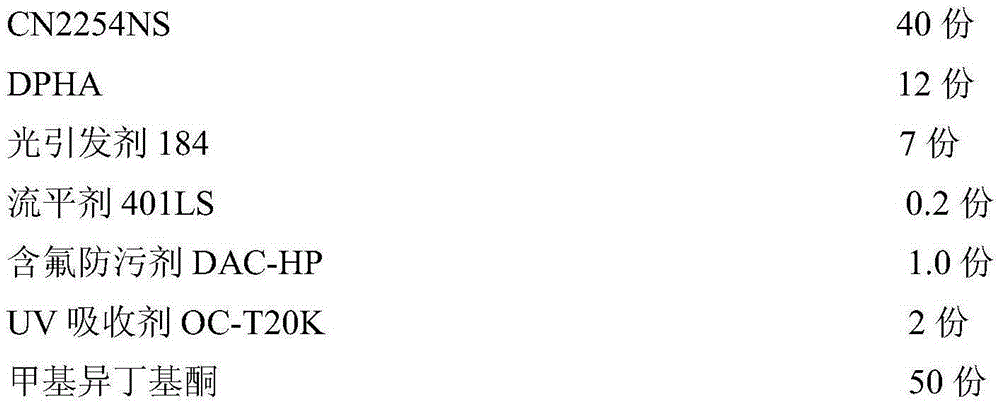

Method used

Image

Examples

Embodiment 1

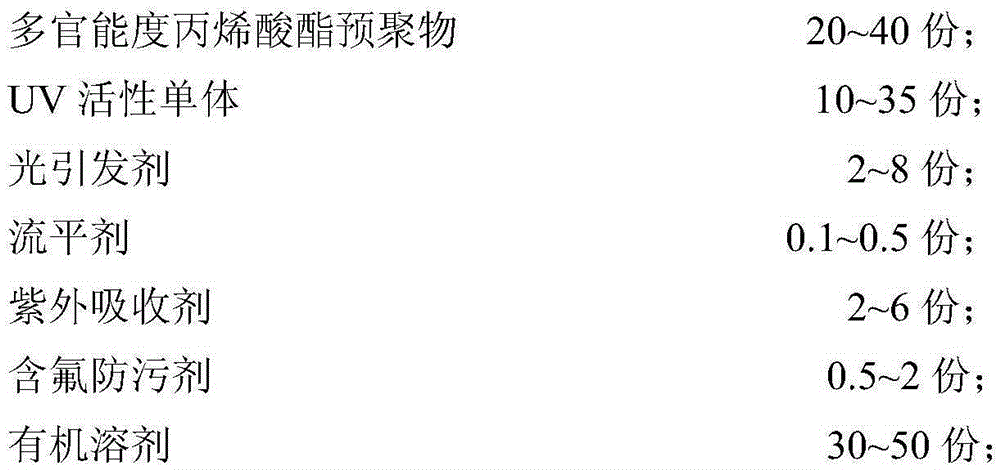

[0025] The components and parts by weight of the UV cut-off antifouling coating composition in the present embodiment are:

[0026]

[0027] Under the condition of avoiding sunlight or ultraviolet light irradiation, relative air humidity less than 60%, to 40 parts of polyester acrylate prepolymer CN2254NS (manufactured by American Sartomer, functionality 2) and 12 parts of dipentaerythritol hexaacrylate DPHA ( Made by Ningbo Jinteng Chemical Co., Ltd., functionality 6) add 1.0 part of modified perfluoropolyether DAC-HP (manufactured by Daikin Corporation of Japan, solid content is 20%), 0.3 part of leveling agent 401LS (manufactured by Dow Corning Company), 50 parts of methyl isobutyl ketone, after fully stirring, add 5 parts of UV absorber OC-T20K (manufactured by Nissan Chemical, with a solid content of 20%) and continue stirring, then add 7 parts of 184 photoinitiators (manufactured by BASF) and stir evenly , and remove impurities with a 1um filter to obtain a photoharde...

Embodiment 2

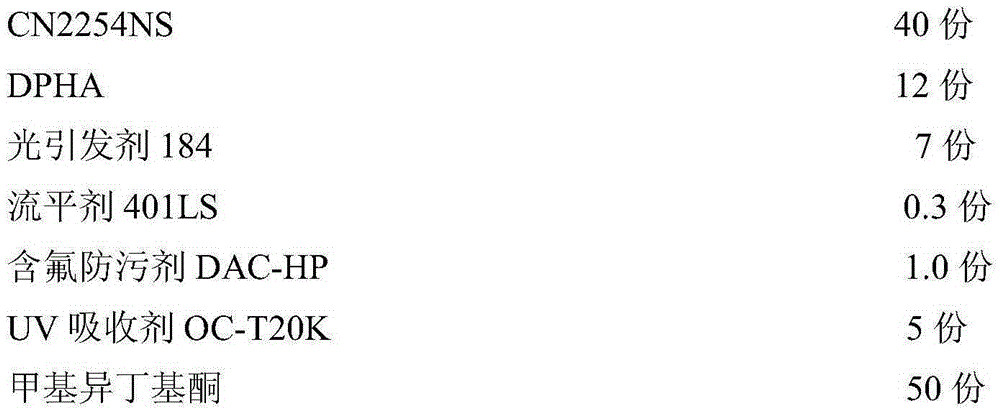

[0030] The components and parts by weight of the UV cut-off antifouling coating composition in the present embodiment are:

[0031]

[0032] Under the condition of avoiding sunlight or ultraviolet light irradiation, relative air humidity less than 60%, to 40 parts of polyester acrylate prepolymer CN2254NS (manufactured by American Sartomer, functionality 2) and 12 parts of dipentaerythritol hexaacrylate DPHA ( Manufactured by Ningbo Jinteng Chemical Co., Ltd., functionality 6) Add 1.0 part of modified perfluoropolyether DAC-HP (manufactured by Daikin Corporation of Japan, solid content is 20%), 0.2 part of leveling agent 401LS (manufactured by Dow Corning Company), 50 parts of methyl isobutyl ketone, after fully stirring, add 2 parts of UV absorber OC-T20K (manufactured by Nissan Chemical, with a solid content of 20%) and continue stirring, then add 7 parts of 184 photoinitiators (manufactured by BASF) and stir evenly , and remove impurities with a 1um filter to obtain a UV...

Embodiment 3

[0035] The components and parts by weight of the UV cut-off antifouling coating composition in the present embodiment are:

[0036]

[0037] Under the condition that avoids sunlight or ultraviolet light irradiation, air relative humidity is less than 60%, to 25 parts of aliphatic urethane acrylate prepolymers CN9006NS (manufactured by U.S. Sartomer, functionality 6) and 20 parts of pentaerythritol triacrylate PETA ( Manufactured by Ningbo Jinteng Chemical Co., Ltd., functionality 3) Add 2 parts of modified perfluoropolyether DAC-HP (manufactured by Daikin Corporation of Japan, solid content is 20%), 0.3 part of leveling agent 401LS (manufactured by Dow Corning Company), 50 parts of methyl isobutyl ketone, stir well and then add 4 parts of UV absorber OC-T20K (manufactured by Nissan Chemical, solid content is 20%) After continuing to stir, add 3 parts of 184 photoinitiator (manufactured by BASF) and stir evenly , and remove impurities with a 1um filter to obtain a UV cut-off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com