Graphene heat dissipation coating as well as preparation method and application thereof

A technology of heat dissipation coating and graphene, applied in the field of coatings, can solve problems such as poor scratch resistance and wear resistance, and achieve the effects of good heat dissipation effect, good scratch resistance and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

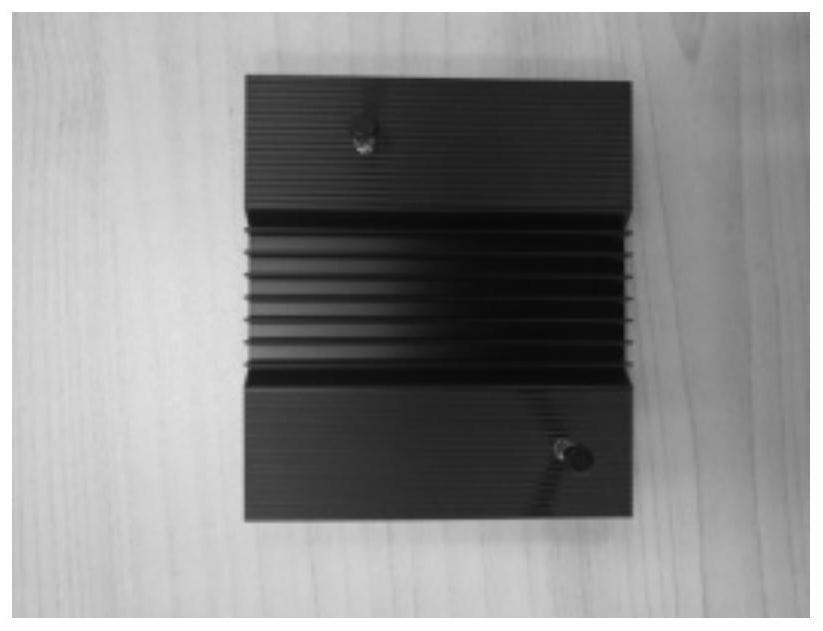

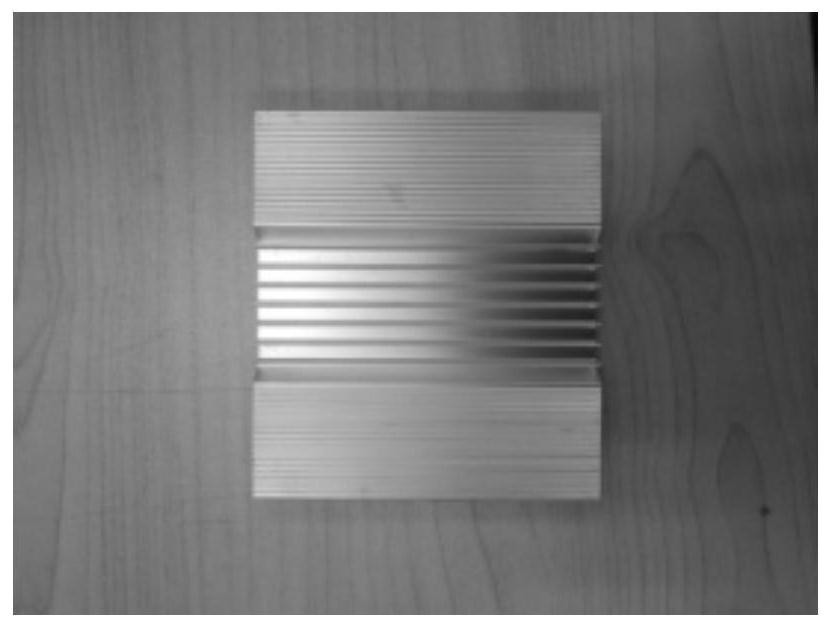

Image

Examples

preparation example Construction

[0040] Correspondingly, the embodiment of the present invention provides a kind of preparation method of graphene heat dissipation paint, it comprises the steps:

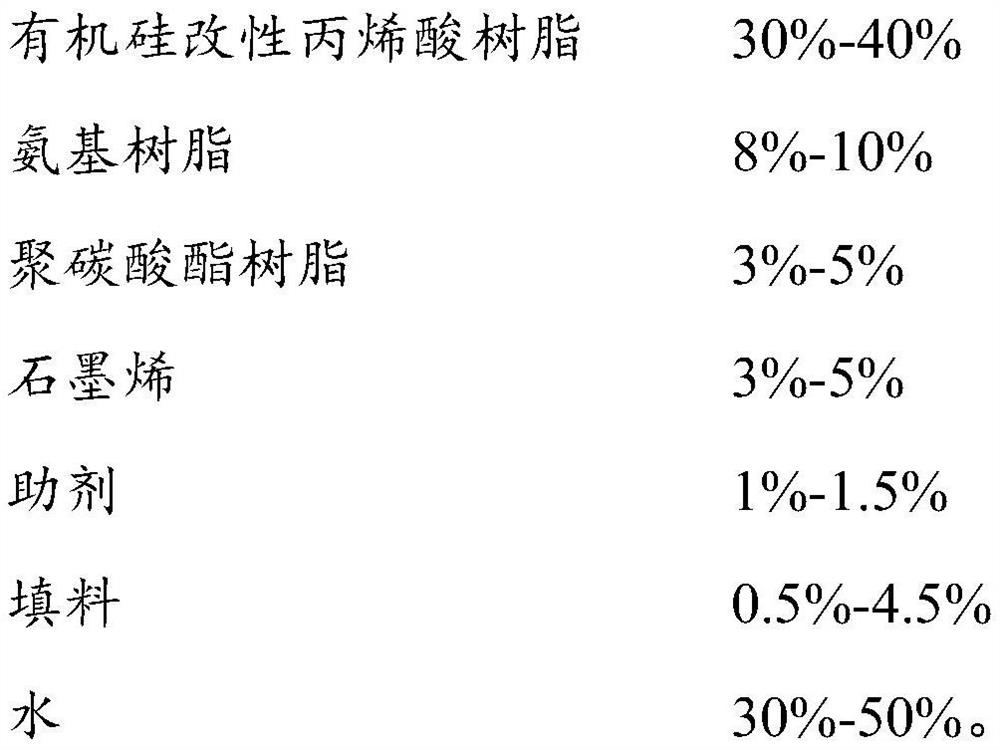

[0041] S1. Provide silicone-modified acrylic resin, amino resin, polycarbonate resin, graphene, additives, fillers and water;

[0042] S2. Mix silicone-modified acrylic resin, amino resin, polycarbonate resin, graphene, additives, fillers and water to obtain a coating.

[0043] In the preparation method of the graphene heat-dissipating coating provided in the embodiment of the present invention, the graphene heat-dissipating coating with the above-mentioned functions can be obtained by mixing the raw materials according to a specific ratio, which has the advantages of simple preparation method and easy implementation .

[0044] Specifically, in S1, prepare materials according to the components and contents provided in the above-mentioned graphene heat dissipation coating.

[0045] In S2, the graphene heat dissipat...

Embodiment 1

[0056] A kind of graphene heat-dissipating coating, its preparation method comprises the steps:

[0057] (1) material preparation: organic silicon-modified acrylic resin, polycarbonate resin, amino resin, graphene, auxiliary agent (BYK-190, 0.3 produced by 0.2wt% defoamer TEGO 902W, 0.5wt% BYK company wt% polyether modified siloxane), deionized water, and fillers are prepared according to the following weight ratio;

[0058]

[0059]

[0060] (2) Mixing: Stir deionized water and additives (TEGO 902W and BYK-190) until completely dissolved, then add fillers (glass powder, ceramic powder and wax powder in a ratio of 3:4:3), Silicone modified acrylic resin (AD-1680 produced by Dongguan Aide Synthetic Materials Co., Ltd.), polycarbonate resin (T5652 produced by Asahi Kasei Co., Ltd.), amino resin (CYMEL303 produced by Cytec Corporation of the United States), graphene ( The model produced by Changzhou Sixth Element Materials Technology Co., Ltd. is SE1231 graphene), polyethe...

Embodiment 2

[0062] A kind of graphene heat-dissipating coating, its preparation method comprises the steps:

[0063] (1) raw material: with silicone modified acrylic resin, polycarbonate resin, amino resin, graphene, auxiliary agent (BYK-190, 0.3wt produced by 0.2wt% defoamer TEGO 902W, 1wt% BYK company % polyether modified siloxane), deionized water, and fillers are prepared according to the following weight ratio;

[0064]

[0065] (2) Mixing: Stir deionized water and additives (TEGO 902W and BYK-190) until completely dissolved, then add fillers (glass powder, ceramic powder and wax powder in a ratio of 3:4:3), Silicone modified acrylic resin (AD-1680 produced by Dongguan Aide Synthetic Materials Co., Ltd.), polycarbonate resin (T5652 produced by Asahi Kasei Co., Ltd.), amino resin (CYMEL303 produced by Cytec Corporation of the United States), graphene ( The model produced by Changzhou Sixth Element Materials Technology Co., Ltd. is SE1231 graphene), polyether modified siloxane, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com