Scraping resistance halogen-free flame retardant thermoplastic elastomer composition and preparation method of composition

A technology of thermoplastic elastomers and compositions, which is applied in the field of processing and modification of polymer materials, can solve problems such as scratch resistance of materials that are not mentioned, and reduce the risk of surface precipitation and blooming, reduce energy consumption, and reduce viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

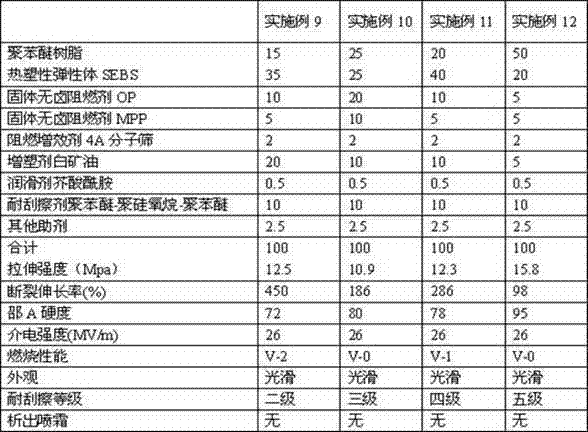

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific embodiments. The following examples are preferred implementation forms of the present invention, but the implementation manners of the present invention are not limited by the following examples.

[0030] Table 1 lists the components required for the preparation of Comparative Example 1 and Examples 1-8. All component amounts are expressed in weight percent. The polyphenylene ether resin has an intrinsic viscosity of 0.45 dl / g, measured in chloroform at 25°C, and is purchased from Japan Asahi Kasei Co., Ltd. as PPE S201A; the styrene-based thermoplastic elastomer SEBS is a linear three-embedded Segment styrene-ethylene / butylene-styrene block copolymer, its polystyrene content is 30%, it is purchased from Kraton Polymer Co., Ltd. with Kraton G1651; Described solid halogen-free flame retardant organic phosphine Salt, purchased from Clariant with OP 1230; the solid halogen-free flame retardant melamine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com