Scraping-resistant UV matt varnish applied to matt membranes and preparation method thereof

A technology of scratch resistance and matte oil, applied in the field of UV matt oil, can solve the problems of easy scratching, poor scratch resistance, poor adhesion of matte film, etc. Simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

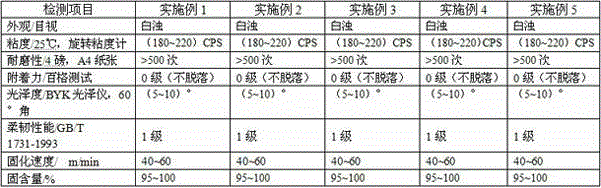

Examples

Embodiment 1

[0041] The preparation method of the anti-scratch UV dumb oil for dumb film of the present embodiment comprises the following preparation steps:

[0042] a. Add 39 parts of 1,6 hexanediol diacrylate and 15 parts of organic matting agent into the mixing pot for pre-dispersion, mix and stir evenly, the stirring speed is 700r / min, and the stirring time is 35min;

[0043] b, then continue to add 5 parts of bisphenol A epoxy acrylic resin, 35 parts of modified polyurethane acrylic resin, 26 parts of tripropylene glycol diacrylate, 3 parts of benzophenone, 4 parts of tertiary amine co-initiator, 4 parts of 2-hydroxy-2-methyl-1-phenylacetone, 4 parts of 1-hydroxycyclohexyl benzophenone, 2 parts of silicone leveling agent, 3 parts of silicone defoamer, mix well, stir Rotating speed is 900r / min, and the time of stirring is 80min, makes oil plant;

[0044] c. Filter the oil with a 320-mesh filter bag to obtain scratch-resistant UV dumb oil for the dumb film.

Embodiment 2

[0046] The preparation method of the anti-scratch UV dumb oil for dumb film of the present embodiment comprises the following preparation steps:

[0047] a. Add 20 parts of 1,6 hexanediol diacrylate and 12 parts of organic matting agent into the stirring pot for pre-dispersion, mix and stir evenly, the stirring speed is 750r / min, and the stirring time is 32min;

[0048]b, then continue to add 8 parts of bisphenol A epoxy acrylic resin, 30 parts of modified polyurethane acrylic resin, 40 parts of tripropylene glycol diacrylate, 2 parts of benzophenone, 5 parts of tertiary amine co-initiator, 3 parts 2-hydroxy-2-methyl-1-phenylacetone, 4 parts 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 2 parts silicone leveling agent, 2 parts silicone Antifoaming agent, mixing and stirring evenly, the rotating speed of stirring is 850r / min, the time of stirring is 85min, makes oil plant;

[0049] c. Filter the oil with a 320-mesh filter bag to obtain scratch-resistant UV dumb oil for the d...

Embodiment 3

[0051] The preparation method of the anti-scratch UV dumb oil for dumb film of the present embodiment comprises the following preparation steps:

[0052] a. Add 24 parts of 1,6 hexanediol diacrylate and 10 parts of organic matting agent into the mixing pot for pre-dispersion, mix and stir evenly, the stirring speed is 800r / min, and the stirring time is 30min;

[0053] b, then continue to add 10 parts of bisphenol A epoxy acrylic resin, 28 parts of modified polyurethane acrylic resin, 32 parts of tripropylene glycol diacrylate, 3 parts of benzophenone, 3 parts of tertiary amine co-initiator, 3 parts of 1-hydroxycyclohexyl benzophenone, 4 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1 part of silicone leveling agent, 2 parts of silicone defoamer, mix and stir Uniformly, the rotating speed of stirring is 800r / min, and the time of stirring is 90min, makes oil plant;

[0054] c. Filter the oil with a 320-mesh filter bag to obtain scratch-resistant UV dumb oil for the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com