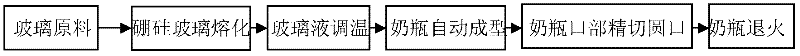

Production method for automatically machining borosilicate glass series feeding bottles

A technology of borosilicate glass and its production method, which is applied in glass blowing machines, feeding bottles, etc., can solve the problems of poor rapid heat and rapid cooling resistance of calcium glass, difficulty in guaranteeing the quality of feeding bottles, and low efficiency of manual operation, achieving chemical Good stability, easy cleaning and inspection, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to examples. It should be understood that the examples described here are only used to explain the present invention, and are not intended to limit the present invention.

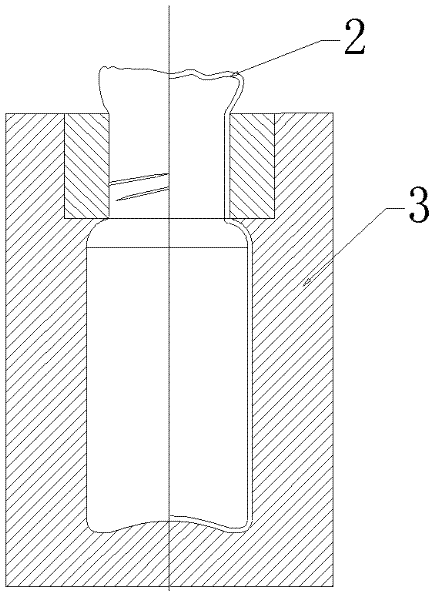

[0020] The borosilicate glass series feeding bottles of the present invention can be in various shapes, 1-waist type; 2-pagoda type; 3-waist pagoda type; 4-ball type; It is divided into three types: large (500)ml, medium (350ml) and small (210ml).

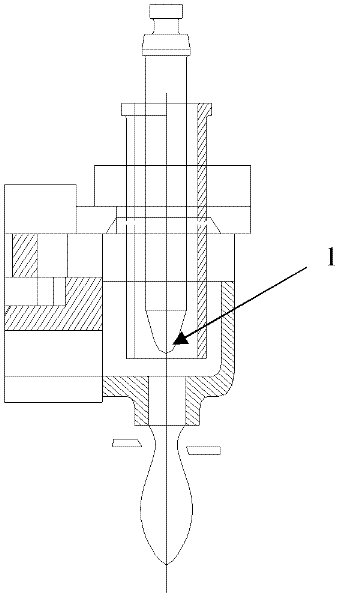

[0021] The manufacturing method of this borosilicate glass automatic mechanism series feeding bottle, the steps of this method are:

[0022] (1) Accurately weigh various raw materials according to the composition requirements of borosilicate glass, pour them into the mixer in turn for mixing, and the mixing uniformity reaches 95% for later use;

[0023]

[0024] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com