Copolymerization transparent nylon and preparation method for same

A transparent and copolymerized technology, applied in the field of nylon materials, can solve the problems of reduced processing performance and resin fluidity, and achieve the effects of reduced regularity, low water absorption, and reduced interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

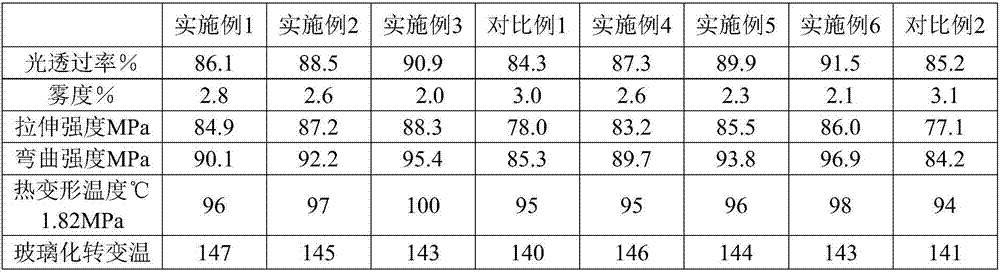

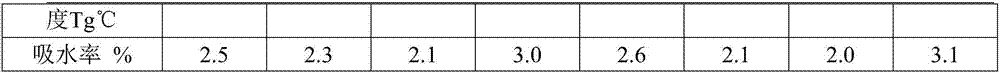

Examples

Embodiment 1

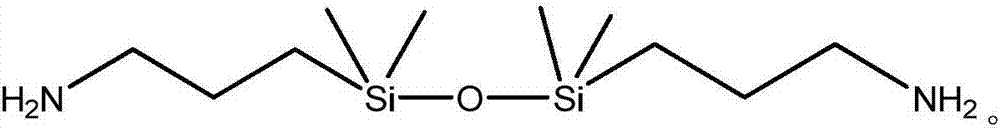

[0031] A copolymerized transparent nylon of the present invention is mainly formed by polycondensation of component A and component B; wherein, component A is formed by polymerization of terephthalic acid and 2-methylpentamethylenediamine in a molar ratio of 1:1 Component B is a salt formed by the polymerization of 1,3-bis(3-aminopropyl)-tetramethyldisiloxane and adipic acid in a molar ratio of 1:1; wherein, component A The mass ratio to component B is 70%:30%.

[0032] The preparation method of the copolymerized transparent nylon of the present embodiment comprises the following steps:

[0033] (1) Put terephthalic acid and 2-methylpentamethylenediamine with a molar ratio of 1:1 into an automatic control polymerization kettle with a stirrer, and react under a pressure of 1 bar, a temperature of 80°C and a nitrogen atmosphere , to obtain component A;

[0034] (2) Adipic acid and 1,3-bis(3-aminopropyl)-tetramethyldisiloxane with a molar ratio of 1:1 are put into an automatic ...

Embodiment 2

[0037] A copolymerized transparent nylon of the present invention is mainly formed by polycondensation of component A and component B; wherein, component A is formed by polymerization of terephthalic acid and 2-methylpentamethylenediamine in a molar ratio of 1:1 Component B is a salt formed by the polymerization of 1,3-bis(3-aminopropyl)-tetramethyldisiloxane and adipic acid in a molar ratio of 1:1; wherein, component A The mass ratio to component B is 80%:20%.

[0038] The preparation method of the copolymerized transparent nylon of the present embodiment comprises the following steps:

[0039] (1) Put terephthalic acid and 2-methylpentamethylenediamine with a molar ratio of 1:1 into an automatic control polymerization kettle with a stirrer, and react under a pressure of 1 bar, a temperature of 80°C and a nitrogen atmosphere , to obtain component A;

[0040] (2) Adipic acid and 1,3-bis(3-aminopropyl)-tetramethyldisiloxane with a molar ratio of 1:1 are put into an automatic ...

Embodiment 3

[0043] A copolymerized transparent nylon of the present invention is mainly formed by polycondensation of component A and component B; wherein, component A is formed by polymerization of terephthalic acid and 2-methylpentamethylenediamine in a molar ratio of 1:1 Component B is a salt formed by the polymerization of 1,3-bis(3-aminopropyl)-tetramethyldisiloxane and adipic acid in a molar ratio of 1:1; wherein, component A The mass ratio to component B is 90%:10%.

[0044] The preparation method of the copolymerized transparent nylon of the present embodiment comprises the following steps:

[0045] (1) Put terephthalic acid and 2-methylpentamethylenediamine with a molar ratio of 1:1 into an automatic control polymerization kettle with a stirrer, and react under a pressure of 1 bar, a temperature of 80°C and a nitrogen atmosphere , to obtain component A;

[0046] (2) Adipic acid and 1,3-bis(3-aminopropyl)-tetramethyldisiloxane with a molar ratio of 1:1 are put into an automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com