PVC (polyvinyl chloride) heat shrinking film and preparation method thereof

A heat-shrinkable film and PVC resin technology, applied to flat products, other household appliances, applications, etc., to achieve uniform shrinkage, simple preparation method, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

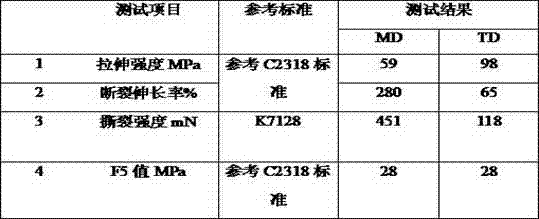

Embodiment 1

[0019] The PVC heat-shrinkable film of the present invention is mainly made of the following raw materials in parts by weight: 90 parts of SG-5 of Shandong Bohui, 1 part of HANKINS NCP-2, 2 parts of ethylene bisstearamide, and 1 part of adipate 2 parts, ESC-1010 antioxidant 2 parts.

[0020] Weigh the raw materials in the above parts by weight; add SG-5, HANKINS NCP-2, ethylene bisstearamide, adipate, ESC-1010 antioxidant into the reactor at 70°C and stir at 160rpm for 5min ;The temperature in the reactor is increased to 280°C, the pressure is lowered to below 90pa, and the polymer melt is obtained by reacting for 1 hour under this condition, and then the prepared polymer melt is extruded, pelletized, and dried to obtain PVC polyester chips; The above-mentioned PVC polyester chips are melt-extruded, die-cast, cast-rolled, biaxially stretched, cooled and shaped, thickness measured, rolled, slitting and rewinding, packaged, and finished. The melt extrusion temperature is 275° C...

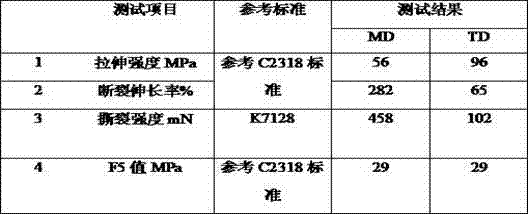

Embodiment 2

[0024] The PVC heat-shrinkable film of the present invention is mainly made of the following raw materials in parts by weight: 100 parts of SG-5 of Shandong Bohui, 5 parts of HANKINS NCP-2, 5 parts of glyceryl monostearate, and 3 parts of adipate parts, 5 parts of ESC-1010 antioxidant.

[0025] Weigh the above raw materials in parts by weight; add SG-5, HANKINS NCP-2, glyceryl monostearate, adipate, ESC-1010 antioxidant into the reaction kettle at 80°C and stir at 220rpm for 10min ;The temperature in the reactor is raised to 300°C, the pressure is lowered to below 90pa, and the polymer melt is obtained by reacting for 3 hours under this condition, and then the prepared polymer melt is extruded, pelletized, and dried to obtain PVC polyester chips; The above-mentioned PVC polyester chips are melt-extruded, die-cast, cast-rolled, biaxially stretched, cooled and shaped, thickness measured, rolled, slitting and rewinding, packaged, and finished. The melt extrusion temperature is 2...

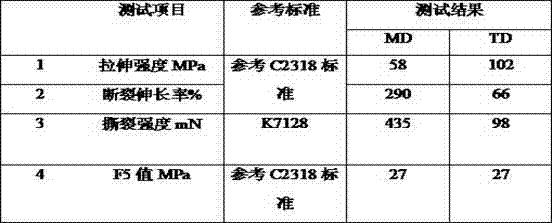

Embodiment 3

[0029] The PVC heat-shrinkable film of the present invention is mainly made of the following raw materials in parts by weight: 95 parts of SG-5 from Shandong Bohui, 3 parts of HANKINS NCP-2, 3 parts of stearyl alcohol, 2 parts of adipate, ESC -1010 antioxidant 3 parts.

[0030] Weigh the above raw materials in parts by weight; add SG-5, HANKINS NCP-2, stearyl alcohol, adipate, ESC-1010 antioxidant into the reaction kettle at 75°C and stir at 195rpm for 7min; The temperature in the kettle is raised to 295°C, and the pressure drops below 90pa. Under these conditions, react for 2 hours to obtain a polymerized melt, and then extrude, pelletize and dry the prepared polymerized melt to obtain PVC polyester chips; Polyester chip melt extrusion, die casting, casting sheet winding, biaxial stretching, cooling and setting, thickness measurement, winding, slitting and rewinding, packaging, and finished products. The melt extrusion temperature is 277° C., the biaxial stretching temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com