Liposome and preparation method thereof

A liposome and system technology, which is applied in the directions of liposome delivery, pharmaceutical formulations, and non-active ingredients medical preparations, etc. problems such as poor properties, and achieve good dispersion and stability, good liposome quality, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

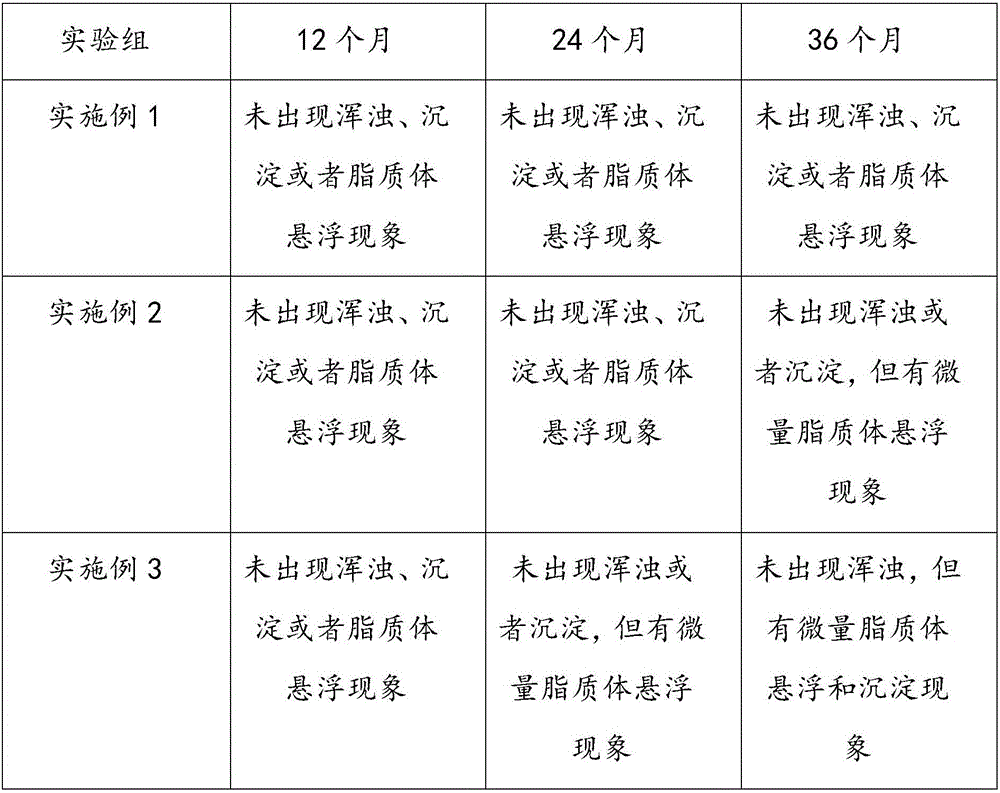

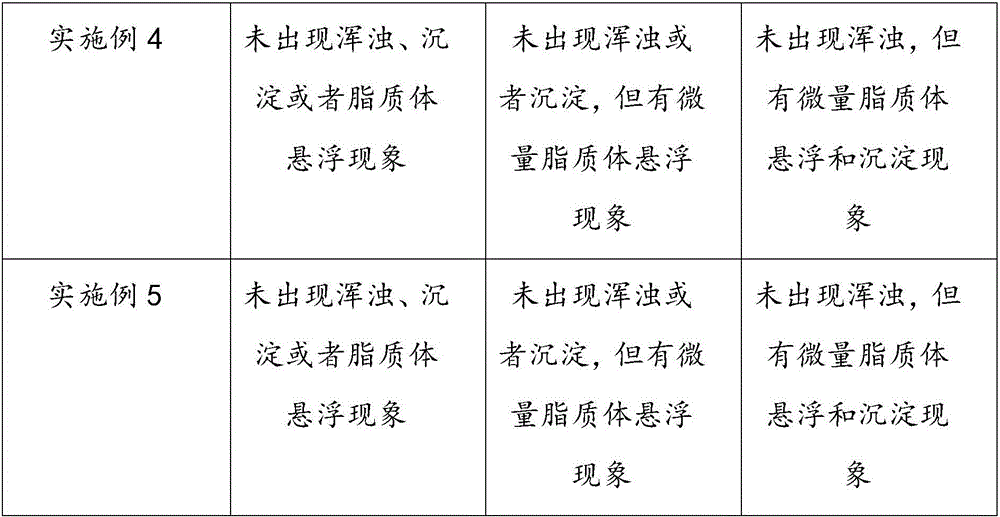

Examples

Embodiment 1

[0042] The liposomes of Example 1 were prepared according to the method described below:

[0043] (1) Under the condition of 20~30℃, according to the ratio of the volume of water to the mass of phospholipid at a ratio of 100:10, add water to the phospholipid and stir and mix for 30 minutes;

[0044] (2) Introduce the mixed system obtained after stirring and mixing into a grinder, and grind for 4 to 5 minutes at 20-40°C;

[0045] (3) The mixed system obtained after grinding is introduced into a grinding machine, and the liposome of Example 1 is obtained by grinding at a temperature of 25-30° C. for 25-35 min.

[0046] At the same time, during the preparation of liposomes in Example 1, turbidity or precipitation was not found in the reaction system; after the liposomes prepared in Example 1 were placed for 60 minutes, no precipitation occurred.

Embodiment 2

[0048] The liposome of Example 2 was prepared according to the method described below:

[0049] (1) Under the condition of 20~30℃, according to the ratio of the volume of water to the mass of phospholipid at a ratio of 100:50, add water to the phospholipid and stir and mix for 30 minutes;

[0050] (2) Introduce the mixed system obtained after stirring and mixing into a grinder, and grind for 4 to 5 minutes at 20-40°C;

[0051] (3) The mixed system obtained after grinding is introduced into a grinding machine, and the liposomes of Example 2 are obtained by grinding at a temperature of 25-30° C. for 25-35 minutes.

[0052] At the same time, during the preparation of liposomes in Example 2, turbidity or precipitation was not found in the reaction system; after the liposomes prepared in Example 2 were placed for 60 minutes, no precipitation occurred.

Embodiment 3

[0054] The liposomes of Example 3 were prepared according to the method described below:

[0055] (1) Under the condition of 20~30℃, according to the ratio of the volume of water to the mass of phospholipid in grams of 100:80, add water to the phospholipid, and stir and mix for 30 minutes;

[0056] (2) Introduce the mixed system obtained after stirring and mixing into a grinder, and grind for 4 to 5 minutes at 20-40°C;

[0057] (3) The mixed system obtained after grinding is introduced into a grinding machine, and the liposomes of Example 3 are obtained by grinding at a temperature of 25-30° C. for 25-35 minutes.

[0058] At the same time, during the preparation of liposomes in Example 3, no turbidity or precipitation was found in the reaction system; after the liposomes prepared in Example 3 were placed for 60 minutes, no precipitation occurred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com