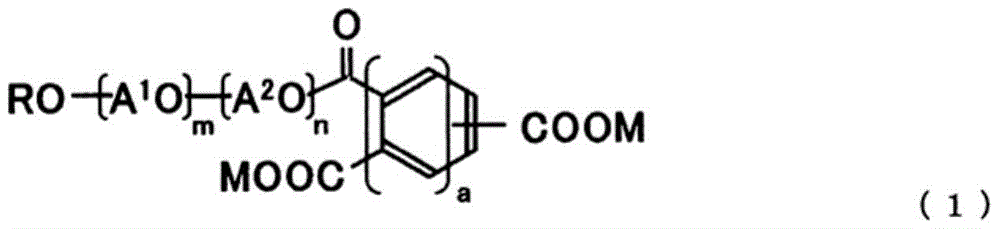

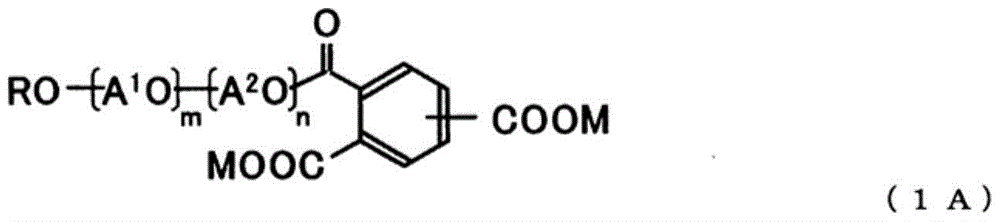

Nonaqueous dispersant and nonaqueous dispersion composition

A non-aqueous dispersant and carbon number technology, which is applied in the field of non-aqueous dispersion compositions, can solve the problems that the effect of the composition is not completely satisfactory, and the non-aqueous dispersion composition cannot fully meet the effect, and achieve excellent dispersion The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0078] Next, the present invention will be described in further detail through examples and comparative examples.

Synthetic example 1

[0079] (Synthesis example 1: Synthesis of polyether ester compound 1)

[0080]Add 288g (2mol) 3,5,5- Trimethyl-1-hexanol (trade name: NONANOL, manufactured by KHneochem Co., Ltd.) and 2 g of potassium hydroxide were heated up to 120°C while stirring after nitrogen substitution. Under the conditions of 120° C. and 0.05 to 0.50 MPa (gauge pressure) under stirring, 705 g (16 mol) of ethylene oxide was added under pressure with nitrogen from a separately prepared pressure vessel through a gas blowing tube. After the addition was completed, it was reacted to a constant internal pressure under the same conditions. Then, in the method, 349 g (6 mol) of propylene oxide was added, and after the addition was completed, it was reacted to a constant internal pressure under the same conditions. Then, the reactant was taken out from the pressure vessel, neutralized to pH 6-7 with hydrochloric acid, and subjected to a reduced-pressure treatment at 100° C. for 1 hour to remove contained wat...

Embodiment 1~5、 comparative example 1~3

[0090] Using polyether ester compounds 1 to 8 as dispersants, non-aqueous dispersion compositions were prepared in the following manner.

[0091] In a 50mL threaded tube, weigh 20.0g of barium titanate powder (average particle size: 0.05μm, measured by electron microscopy using SEM), 5.0g of propylene glycol monomethyl ether acetate, and 1.4g of a dispersant, and use a rotary The revolving mixer was used to stir for 5 minutes to perform pre-dispersion. Then, using 0.5 mm zirconia beads, dispersion was carried out with a bead mill for 4 hours to obtain a slurry-like non-aqueous dispersion composition. In addition, the SP value of propylene glycol monomethyl ether acetate is 8.7 (cal / cm 3 ) 1 / 2 .

[0092] The non-aqueous dispersion compositions obtained using the polyether ester compounds 1-5 were used as Examples 1-5, and the non-aqueous dispersion compositions obtained using the polyether ester compounds 6-8 were referred to as Comparative Examples 1-3.

[0093] (dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Sp value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com