Water-soluble polymer composition, production method for water-soluble polymer composition, and application for water-soluble polymer composition

A technology of water-soluble polymers and compositions, applied in chemical instruments and methods, sustainable manufacturing/processing, dissolution, etc., can solve problems such as pipe blockage, increase in water intake and discharge, and decrease in cooling efficiency, so as to avoid Foaming, excellent effect, excellent dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116]

[0117] 650 g of water and 17 g of a 30% sodium hypophosphite aqueous solution were poured into a flask equipped with a stirrer and a capacitor, and the temperature was maintained at 80°C. A liquid obtained by mixing 1,025 g of 80% acrylic acid aqueous solution (hereinafter also referred to as "80%AA") and 180 g of tert-butylacrylamide (hereinafter also referred to as "TBAM") was continuously supplied to the flask for 4 hours each. , and 30% sodium hypophosphite aqueous solution 83g, 30% sodium persulfate aqueous solution 83g, carry out polymerization reaction. After completion of the supply, the reaction liquid was further kept at 80° C. for 1 hour to react. The reaction solution was kept at 80° C., and 48% sodium hydroxide aqueous solution and deionized water were supplied to obtain an aqueous solution (water-soluble polymer composition E1) containing the water-soluble polymer E1 with a solid content concentration of 40% and a pH of 3.0. .

[0118] When the weigh...

Embodiment 2~11 and comparative example 1~4

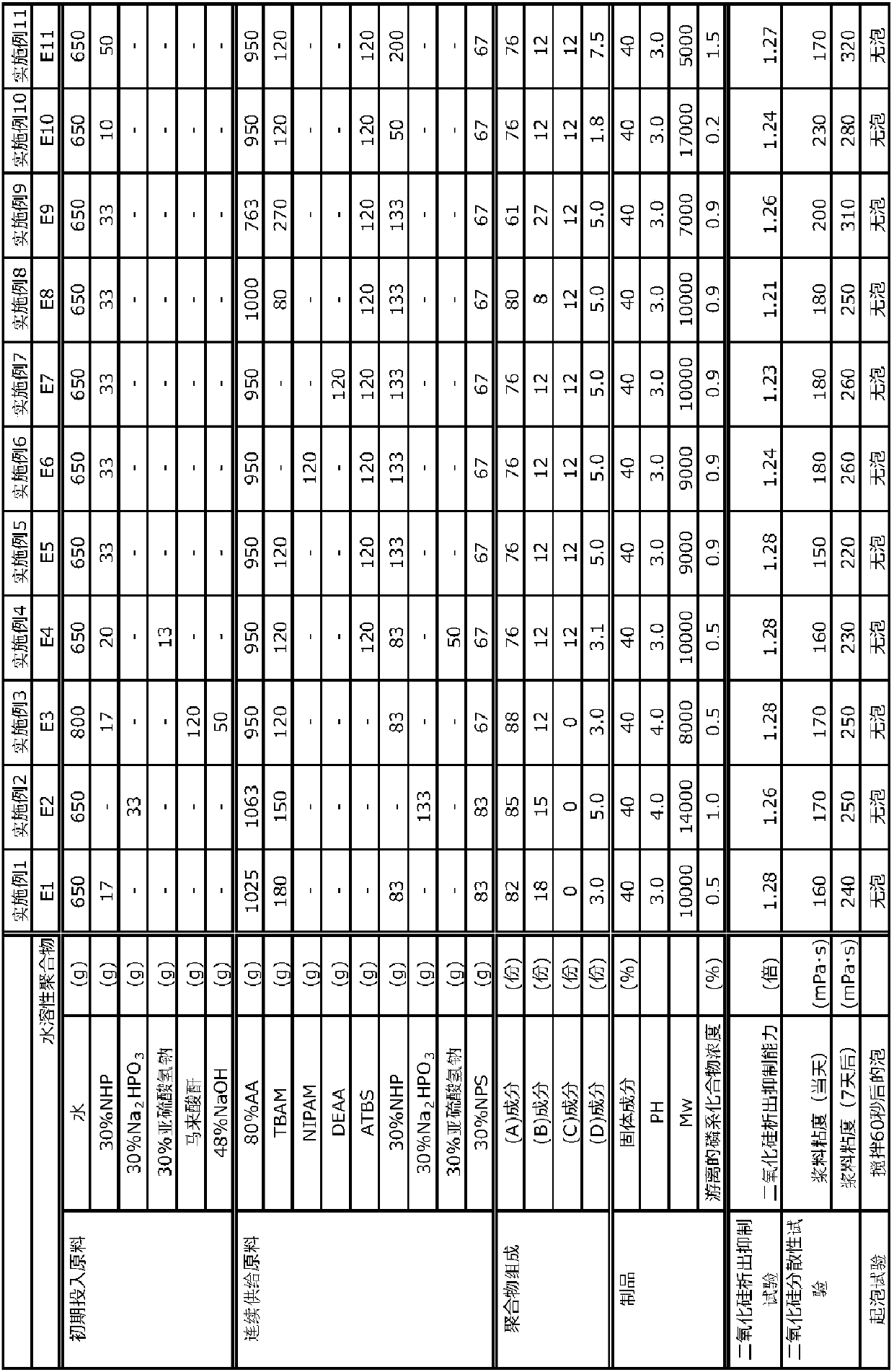

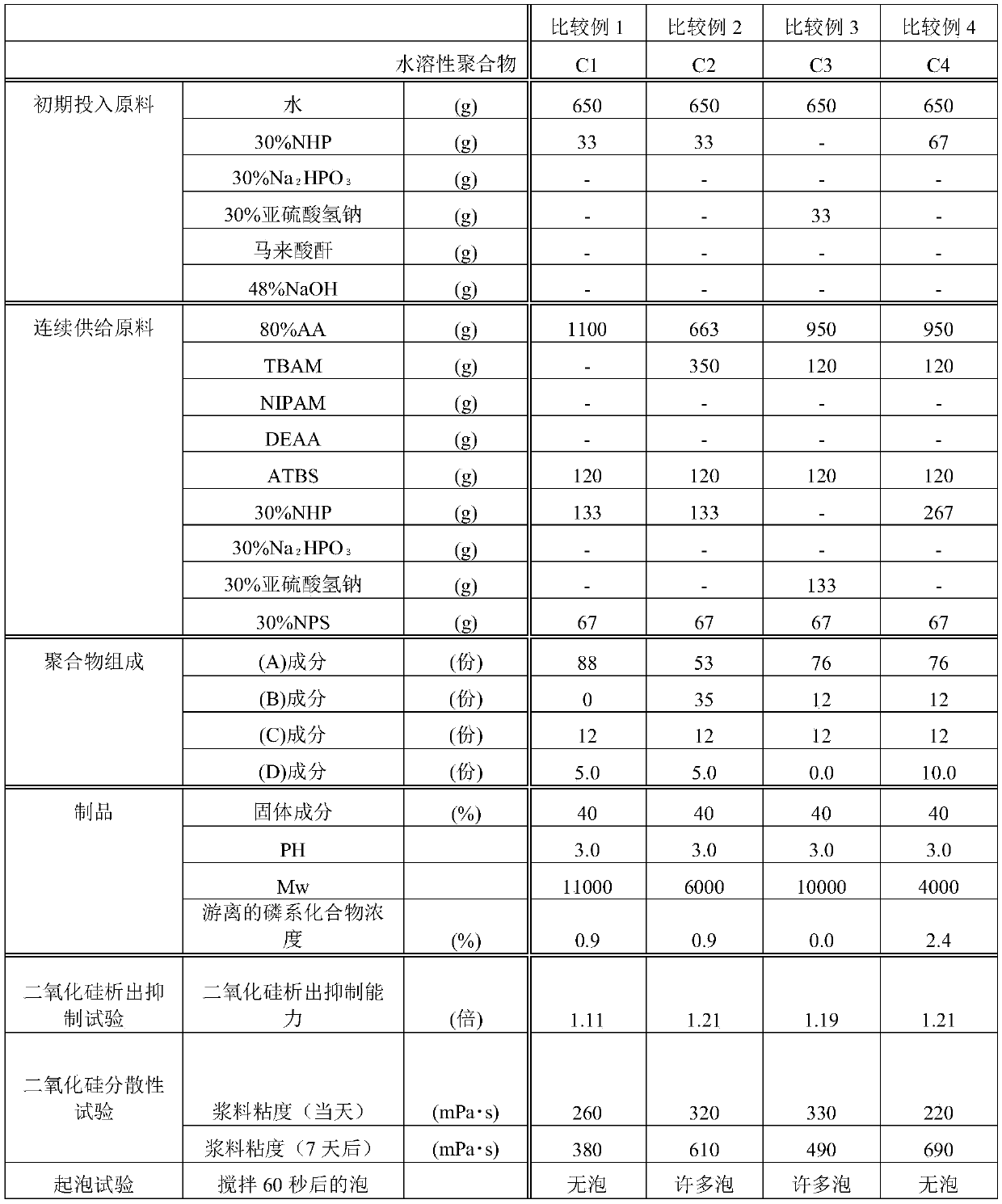

[0130] Except that the types of raw materials and their usage amounts during polymerization were set as in Table 1 and Table 2, the same operation as in Example 1 was carried out to obtain water-soluble polymer compositions E2 to E11 and C1 with a solid content concentration of 40%. ~C4. The weight average molecular weight of each polymer, the pH of 40% aqueous solution, and evaluation as a scale inhibitor and a dispersant were performed similarly to Example 1, and the results are shown in Table 1 and Table 2.

[0131] [Table 1]

[0132]

[0133] [Table 2]

[0134]

[0135] The details of the compounds shown in Table 1 and Table 2 are as follows.

[0136] 30% NHP: 30% sodium hypophosphite aqueous solution

[0137] 30%Na 2 HPO 3 : 30% disodium hydrogen phosphite pentahydrate aqueous solution

[0138] 48% NaOH: 48% sodium hydroxide aqueous solution

[0139] 80% AA: 80% acrylic acid in water

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com