Multifunctional nano zinc oxide suspension and its prepn.

A nano-zinc oxide and suspension technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve problems such as difficulties, changes in application systems, large specific surface and surface energy, etc., and achieve good dispersion stability , easy to operate, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

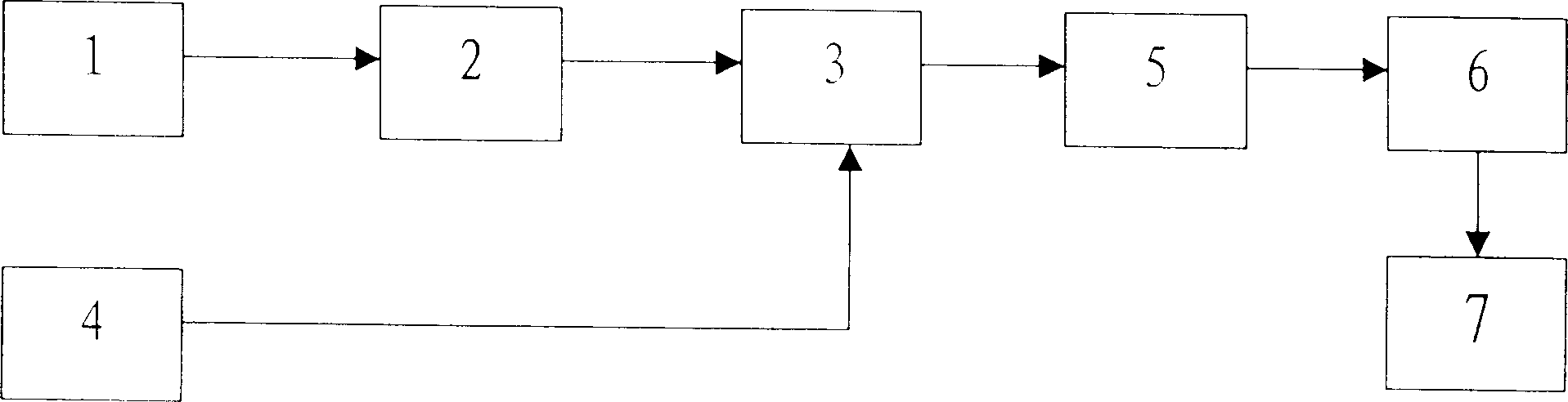

Method used

Image

Examples

Embodiment 1

[0015] This example is a multifunctional nano-zinc oxide suspension and its preparation method

[0016] 1. Preparation method: The different composite components added as required during the preparation process are: modified nano-zinc oxide, non-ionic dispersion stabilizer and different solvents: isopropanol or water. The components and their contents are: Modified nano-zinc oxide: polyethylene glycol: Virahol (or water)=5%: 0.5%: 94.5%, but the ratio sum of each component has satisfied 100% (percentage by weight); earlier the dispersion stabilizer Add it into the solvent and mix evenly, then add the modified nano-zinc oxide while stirring, and stir at room temperature for 0.5 hours after the addition is completed to prepare a stable suspension. Among them, the modified nano-zinc oxide can be organically or / and inorganically modified, and can also be calcium carbonate and mica as a compounding agent. The ratio of the components can also be added: modified nano-zinc oxide: calc...

Embodiment 2

[0019] This example is a multifunctional nano-zinc oxide suspension and its preparation method

[0020] 1. Preparation method: The different composite components added as required during the preparation process are: modified nano-zinc oxide, non-ionic dispersion stabilizer and different solvents: ethyl acetate or water. The components and their contents are: Modified nano zinc oxide: fatty alcohol polyoxyethylene ether: ethyl acetate (or water)=20%: 5%: 75%, but the ratio sum of each component has satisfied 100% (percentage by weight); The stabilizer is added into the solvent and mixed uniformly, then the modified nano-zinc oxide is added while stirring, and after the addition is completed, the mixture is stirred at room temperature for 1 hour to prepare a stable suspension. Wherein, modified nano-zinc oxide can also add titanium dioxide or montmorillonite as a compounding agent in addition to organic or / and inorganic modification, and the formula ratio that can also be added ...

Embodiment 3

[0023] This example is a multifunctional nano-zinc oxide suspension and its preparation method

[0024]1. Preparation method: The different composite components added as required during the preparation process are: modified nano-zinc oxide, polymer dispersion stabilizer and different solvents: xylene or ethylene glycol, and the components and contents are : modified nano zinc oxide: polyacrylic acid salt: xylene (or ethylene glycol)=50%: 10%: 40%, but the ratio sum of each component has satisfied 100% (percentage by weight); first the dispersion is stabilized Add the agent into the solvent and mix evenly, then add the modified nano-zinc oxide while stirring, and stir at room temperature for 2 hours after the addition, to prepare a stable suspension. Wherein, modified nano-zinc oxide can also add silicon dioxide and kaolin as compounding agents except organic or / and inorganic modification, and their formula ratio is: modified nano-zinc oxide: silicon dioxide: kaolin=96.5% : 2%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com