Electrically conductive paste and metal thin film

A technology of conductivity and metal particles, applied in conductive coatings, metal pattern materials, conductive layers on insulating carriers, etc., can solve problems such as insufficient performance and achieve excellent dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

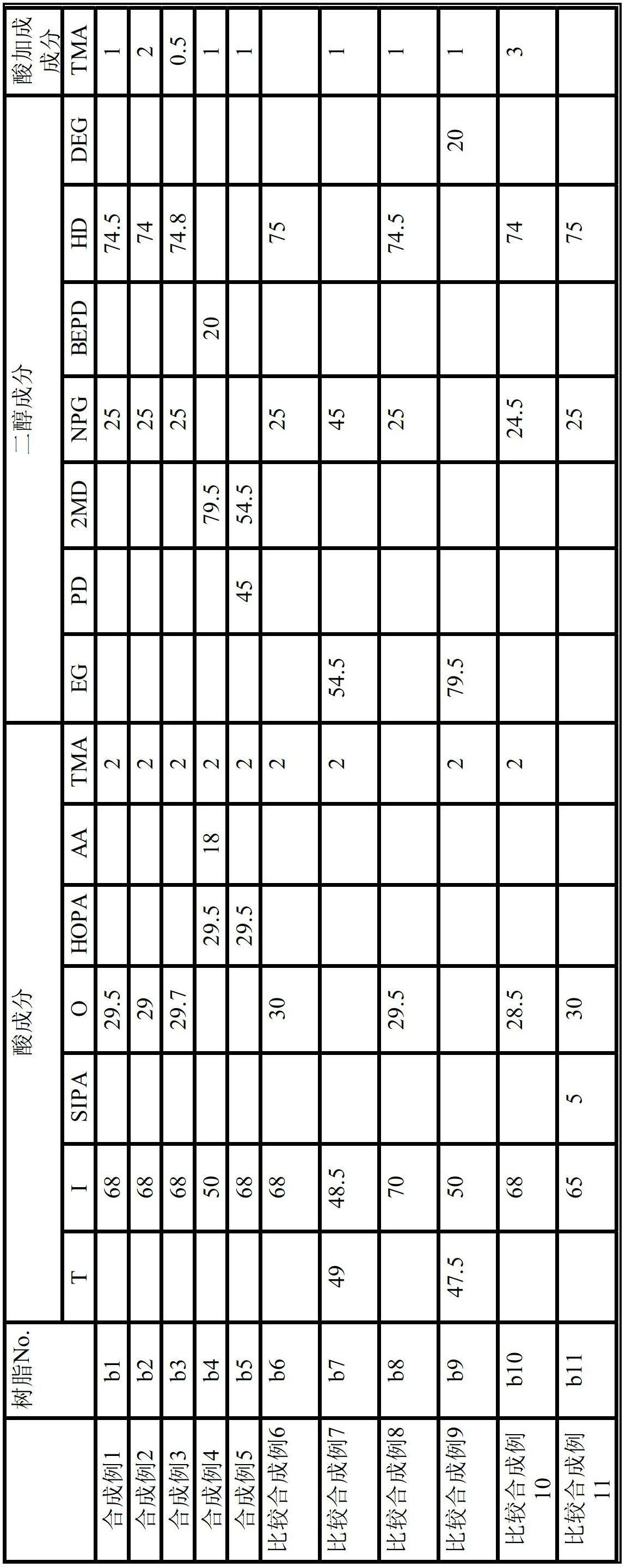

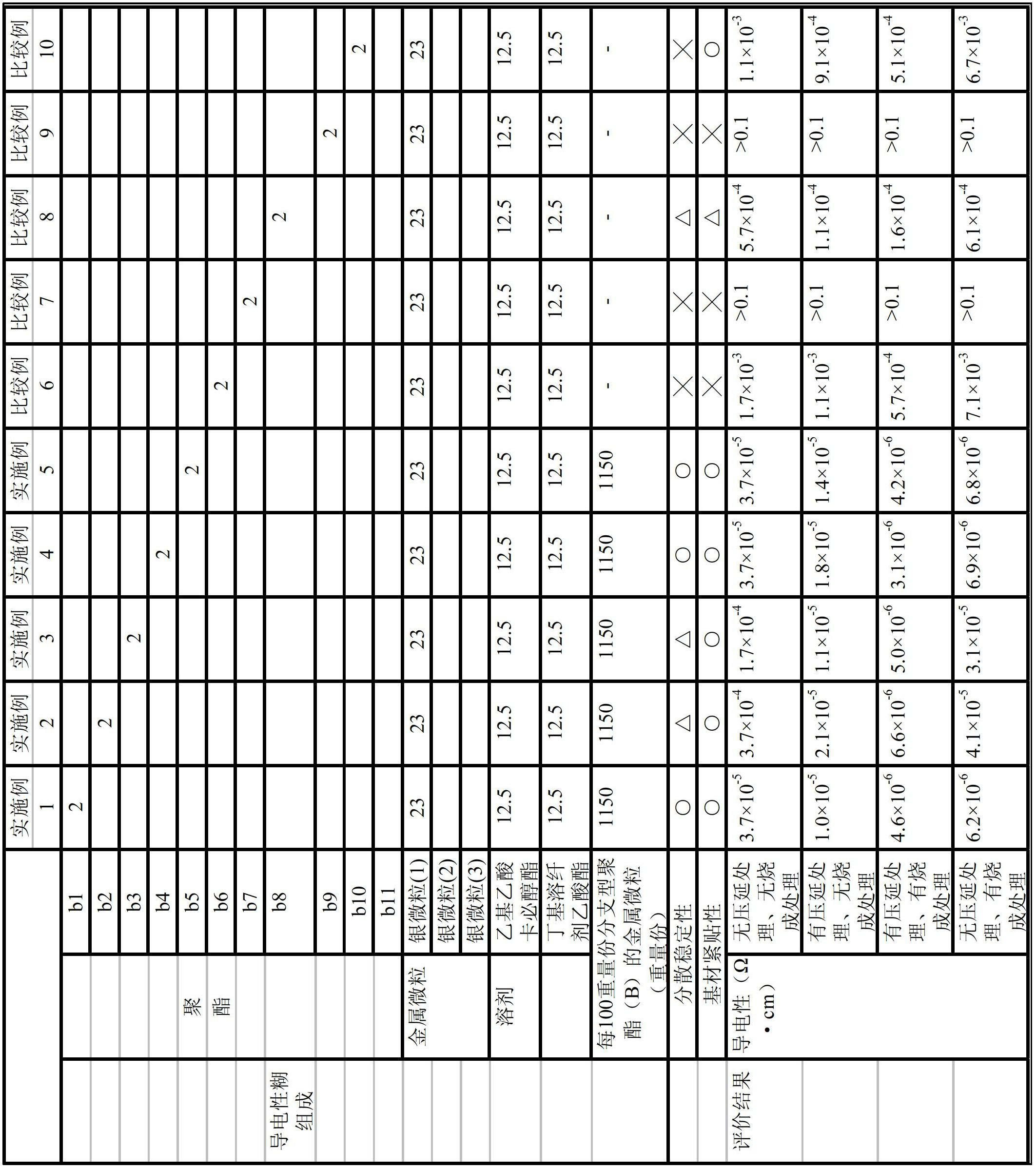

[0049] Hereinafter, examples are given to further describe the present invention in detail, but the present invention is not limited to the examples at all. In addition, the measured value described in an Example is the value measured by the following method. In addition, unless otherwise stated, a part means a weight part.

[0050] Hereinafter, the abbreviations of the compounds shown in this paper and the tables in the examples represent the following compounds respectively:

[0051] T: Terephthalic acid

[0052] I: Isophthalic acid

[0053] O: phthalic acid

[0054] SIPA: Sodium isophthalic acid-5-sulfonate

[0055] HOPA: Hydrogenated phthalic acid

[0056] AA: adipic acid

[0057] SA: Sebacic acid

[0058] TMA: trimellitic anhydride

[0059] NPG: Neopentyl glycol

[0060] EG: ethylene glycol

[0061] PD: 1,5-pentanediol

[0062] HD: 1,6-Hexanediol

[0063] 2MD: 2-methyl-1,3-propanediol

[0064] BEPD: 2-Butyl-2-ethyl-1,3-propanediol

[0065] DEG: diethylene gl...

Synthetic example 1

[0087] Synthesis example 1 Synthesis of carboxyl-containing branched polyester (b1)

[0088] 131.9 parts of dimethyl isophthalate, 48.0 parts of neopentyl glycol, 122.0 parts of 1,6-hexanediol and tetrabutyl titanate were placed in a reaction vessel equipped with a thermometer, a stirrer, and a Liebig cooling tube. 0.1 part of oxyester, heated at 150~230°C for 180 minutes, after transesterification, 43.7 parts of phthalic anhydride and 3.8 parts of trimellitic anhydride were added, and the esterification reaction was carried out at 200~250°C for 60 minutes. Then, while raising the temperature to 260° C., the system was gradually decompressed, and it became 0.3 mmHg or less after 10 minutes. After reacting under these conditions for 60 minutes, the reaction system was returned to normal pressure in a nitrogen atmosphere, and the temperature of the system was set to 220°C. 1.9 parts of trimellitic anhydride was added and stirred at 220° C. for 45 minutes in a nitrogen atmospher...

Synthetic example 2

[0089] Synthesis example 2 Synthesis of carboxyl-containing branched polyester (b2)

[0090] In a reaction vessel equipped with a thermometer, a stirrer, and a Liebig cooling tube, 131.9 parts of dimethyl isophthalate, 48.0 parts of neopentyl glycol, 122.0 parts of 1,6-hexanediol and 0.1 parts of tetrabutoxy titanate were charged Parts, heated at 150~230°C for 180 minutes, after transesterification, 42.9 parts of phthalic anhydride and 3.8 parts of trimellitic anhydride were added, and esterification reaction was carried out at 200~250°C for 60 minutes. Then, while raising the temperature to 260° C., the pressure in the system was gradually reduced to 0.3 mmHg or less after 10 minutes. After reacting under these conditions for 60 minutes, the reaction system was returned to normal pressure in a nitrogen atmosphere, and the temperature of the system was set to 220°C. 3.8 parts of trimellitic anhydride were added, and it stirred at 220 degreeC for 45 minutes in the nitrogen atm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com