Black ceramic ink and preparation method thereof

A black ceramic and ink technology, applied in inks, household appliances, applications, etc., can solve the problems of worn printer nozzles, unstable sol, easy agglomeration, etc., and achieve the effect of improving tinting strength and excellent dispersion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

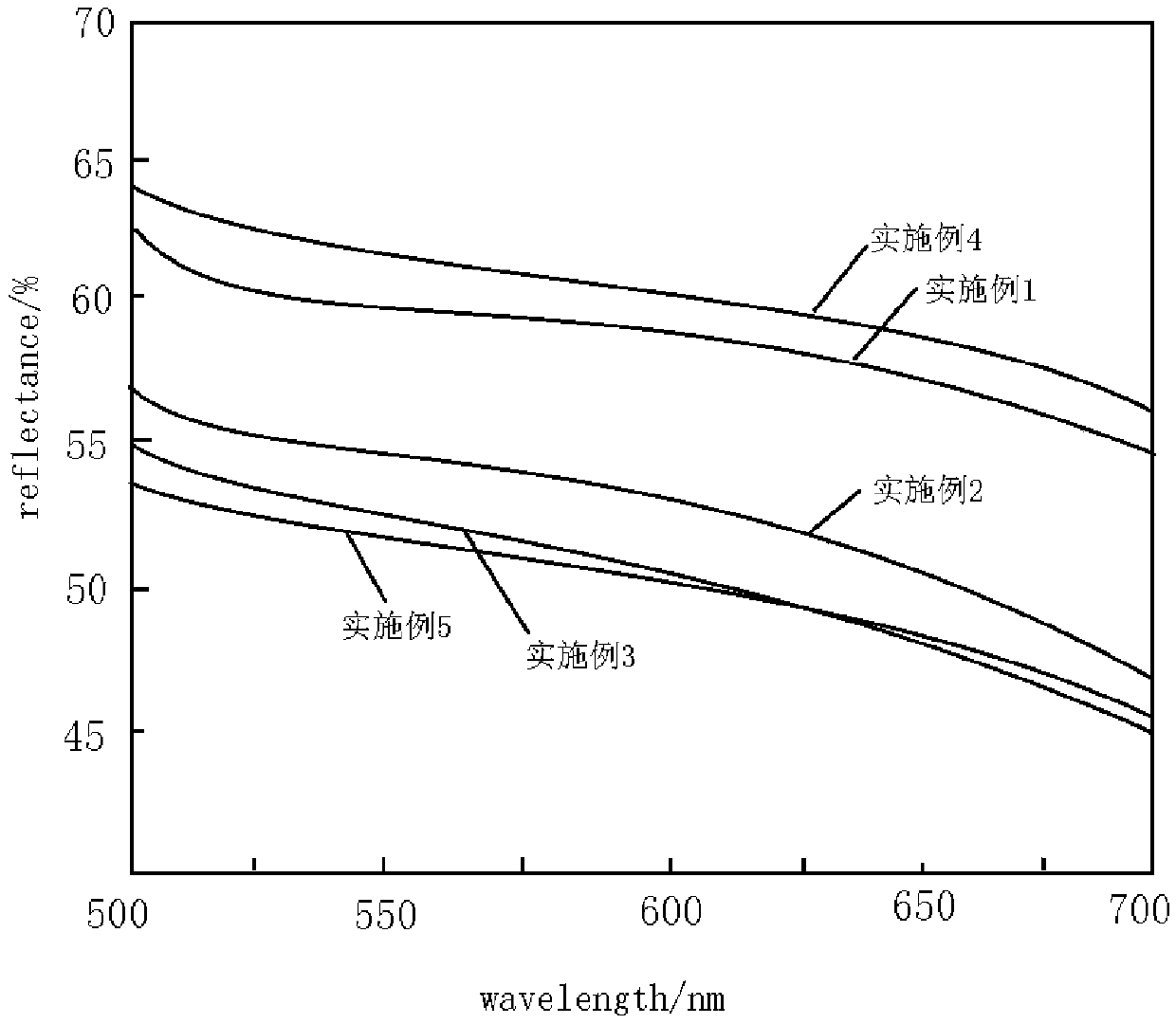

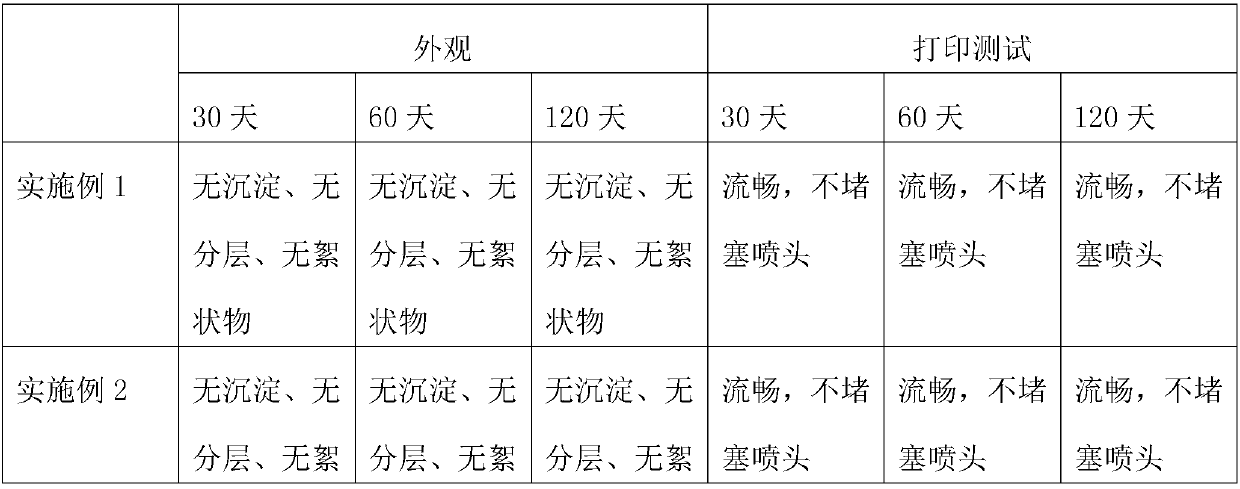

Embodiment 1

[0028] A kind of black ceramic ink, which includes various components by mass percentage: black colorant 25%; solvent 60%; dispersant BYK-2055 5%; organic bentonite 3%; wetting agent Anti-terra-U 0.6 %; surfactant 6%; defoamer 0.4%; the black pigment is copper chrome black doped with a small amount of alumina, and the molar ratio of copper chrome black to alumina is 1:0.02; the surface active The solvent is a mixture of perfluorooctanoic acid and fluorocarbon oil at a mass ratio of 1:1; the solvent includes the following raw materials in parts by weight: 7 parts of dimethyl carbonate and 12 parts of ethylene glycol ether. Wherein, the particle diameters of the copper chrome black and alumina are both ≤1.5 μm.

[0029] The preparation method of above-mentioned black ceramic ink, comprises the following steps:

[0030] (1) Prepare all raw materials according to weight percentage; add dispersant, solvent, organic bentonite, wetting agent, and surfactant into the container togeth...

Embodiment 2

[0035]A kind of black ceramic ink, which includes various components by mass percentage: black pigment 28%; solvent 56%; dispersant BYK-2055 3%; organic bentonite 4.4%; wetting agent Anti-terra-U 0.8 %; surfactant 7%; defoamer 0.8%; the black pigment is copper chrome black doped with a small amount of alumina, and the molar ratio of copper chrome black to alumina is 1:0.03; the surface active The solvent is a mixture of perfluorooctanoic acid and fluorocarbon oil at a mass ratio of 1:1; the solvent includes the following raw materials in parts by weight: 9 parts of dimethyl carbonate and 15 parts of ethylene glycol ether. Wherein, the particle diameters of the copper chrome black and alumina are both ≤1.5 μm.

[0036] The preparation method of above-mentioned black ceramic ink, comprises the following steps:

[0037] (1) Prepare all raw materials according to weight percentage; add dispersant, solvent, organic bentonite, wetting agent, and surfactant into the container togeth...

Embodiment 3

[0042] A kind of black ceramic ink, which includes various components by mass percentage: black pigment 26%; solvent 59%; dispersant BYK-2055 6%; organic bentonite 3%; wetting agent Anti-terra-U 0.3 %; surfactant 5%; defoamer 0.7%; the black pigment is copper chrome black doped with a small amount of alumina, and the molar ratio of copper chrome black to alumina is 1:0.04; the surface active The solvent is a mixture of perfluorooctanoic acid and fluorocarbon oil at a mass ratio of 1:1; the solvent includes the following raw materials in parts by weight: 10 parts of dimethyl carbonate and 18 parts of ethylene glycol ether. Wherein, the particle diameters of the copper chrome black and alumina are both ≤1.5 μm.

[0043] The preparation method of above-mentioned black ceramic ink, comprises the following steps:

[0044] (1) Prepare all raw materials according to weight percentage; add dispersant, solvent, organic bentonite, wetting agent, and surfactant into the container togeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com