Method for preparing nano fluorescent pigment dispersion

A pigment dispersion and nano-fluorescence technology, applied in the direction of organic dyes, etc., can solve the problems of poor storage stability, uneven particle size distribution of fluorescent pigment paste, easy precipitation, etc., to achieve small particle size, avoid stability decline, and not easy Precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

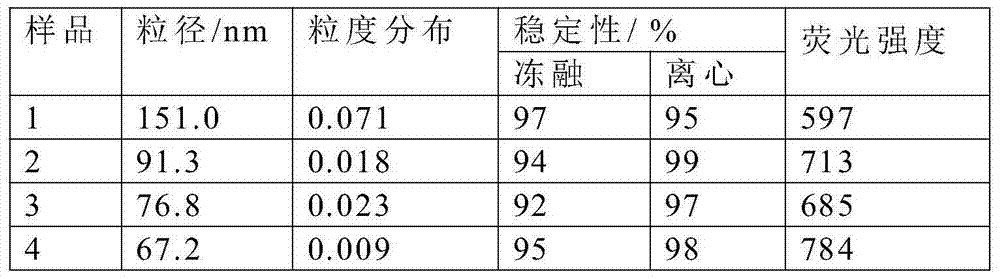

Embodiment 1

[0026] Take 0.2 g of 11-methacryloyloxy sodium undecyl sulfate in 83.1 g of deionized water and stir until completely dissolved to obtain an aqueous phase. Take 0.1g of Fluorescent Yellow 8G in a mixed solution of 5g of styrene, 5g of methyl methacrylate and 1g of acetone, heat and stir until completely dissolved, add 0.5g of hexadecane to obtain an oil phase, and stir at a speed of 1000r / min The oil phase was added dropwise to the water phase in a device, treated in a high-speed emulsifier for 30 minutes, and then placed in an ultrasonic cell pulverizer for ultrasonic treatment in an ice-water bath for 15 minutes to obtain a fine emulsion. Transfer the fine emulsion into the reaction kettle, bring the temperature up to 80°C, slowly add ammonium persulfate (0.1g dissolved in 5g of water) dropwise, keep the reaction for 3 hours, take it out, cool to room temperature, filter with 500nm microporous filter paper to remove impurities, and then adding sodium bicarbonate to adjust th...

Embodiment 2

[0028] Take 0.3 g of sodium propyl tetradecyl maleate sulfonate in 71.5 g of deionized water, and stir until completely dissolved to obtain an aqueous phase. Take 0.1g of Fluorescent Red 5B in a mixed solution of 15g of butadiene, 5g of methyl methacrylate and 2.5g of acetone, heat until it is completely dissolved, add 0.5g of cetyl alcohol to obtain an oil phase, and heat it at a speed of 1000r / min The oil phase was added dropwise to the water phase in a stirrer, treated in a high-speed emulsifier for 30 minutes, and then placed in an ultrasonic cell pulverizer for ultrasonic treatment in an ice-water bath for 15 minutes to obtain a fine emulsion. Transfer the fine emulsion into the reaction kettle, bring the temperature up to 80°C, slowly add ammonium persulfate (0.1g dissolved in 5g of water) dropwise, keep the reaction for 3 hours, take it out, cool to room temperature, filter with 500nm microporous filter paper to remove impurities, and then adding sodium bicarbonate to a...

Embodiment 3

[0030] Take 1.2 g of 11-crotonyloxy sodium undecyl sulfate in 55.6 g of deionized water, stir until completely dissolved, and obtain an aqueous phase. Take 0.9g fluorescent yellow 8G in 20g dicyclopentadiene, 10g butyl methacrylate and 6g propanol mixed solution, heat until completely dissolved, add 1g hexadecane to obtain oil phase The oil phase was added dropwise to the water phase in a stirrer, treated in a high-speed emulsifier for 40 minutes, and then placed in an ultrasonic cell pulverizer for ultrasonic treatment in an ice-water bath for 20 minutes to obtain a fine emulsion. Transfer the fine emulsion into the reaction kettle, bring the temperature up to 80°C, slowly add ammonium persulfate (0.3g dissolved in 5g water) dropwise, keep the reaction for 3 hours, take it out, cool to room temperature, filter with 500nm microporous filter paper to remove impurities, and then adding sodium bicarbonate to adjust the pH to 7-8 to obtain nano fluorescent pigment dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com