Polymer coated inorganic pigment paste for color modulation of production line and preparation method thereof

A technology of inorganic pigments and polymers, which is applied in the treatment of pigment pastes and dyeing polymer organic compounds, etc. It can solve the problems of low adsorption force of dispersants, decreased coloring power of inorganic pigment pastes, and easy foaming, etc. small diameter, high tinting strength and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

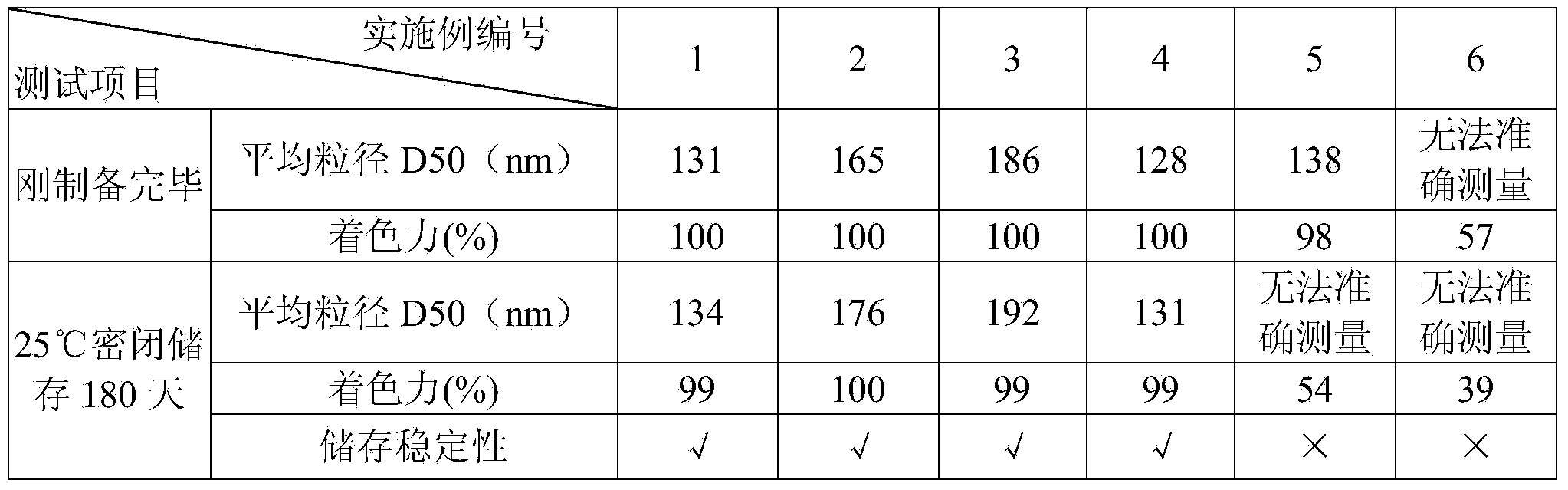

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing the above-mentioned polymer-coated inorganic pigment color paste for color matching in the production line, which includes the following steps:

[0041]a) Disperse the inorganic pigment accounting for 40-80% of the mass ratio of the low-boiling point solvent into the low-boiling point solvent, and sequentially add the silane coupling agent accounting for 5-15% of the mass ratio of the inorganic pigment, accounting for silane coupling agent mass ratio of 50-100% deionized water, react while stirring to get the initial inorganic pigment slurry;

[0042] b) adding a polymer accounting for 10-40% of the mass fraction of the inorganic pigment to the initial inorganic pigment slurry, after grinding and dispersing on a sand mill, adding deionized water accounting for 80-200% of the mass ratio of the low boiling point solvent, and then Adjusting the pH value to 8-9, mixing evenly, and filtering to obtain a polymer-coate...

Embodiment 1

[0052] Disperse 65 grams of carbon black into 160 grams of acetone, then add 4.5 grams of silane coupling agent KH-550, 5 grams of KH-602 and 5 grams of deionized water dropwise, and react at room temperature for 6 hours at a stirring speed of 500r / min , then add 6.5 grams of styrene-acrylic resin, after grinding and dispersing 3 times on a small sand mill in the laboratory, add 128 grams of deionized water, then add a certain amount of triethanolamine, stir evenly, and make the pH of the system be 8 After mixing evenly, the acetone and part of the water in the system were distilled off under reduced pressure at 30°C and 0.02MPa pressure, so that the styrene-acrylic resin was deposited and coated on the surface of the carbon black pigment, and finally 130 grams of polymer were obtained. Coated carbon black pigment concentrate.

[0053] Add 3 grams of sodium lauryl sulfate, 20 grams of glycerol, 10 grams of ethylene glycol, 0.15 grams of polysiloxane defoamer, and 0.015 grams o...

Embodiment 2

[0055] Disperse 50 grams of iron oxide red pigment into 100 grams of ethanol, then add 5 grams of silane coupling agent KH-570 and 4 grams of deionized water dropwise, and react for 24 hours at a stirring speed of 800 r / min, then add 5 grams of benzene Ethylene-itaconic acid copolymer, stir evenly, grind and disperse 10 times on a small sand mill in the laboratory, add 200 grams of deionized water and an appropriate amount of 30% NaOH aqueous solution to make the system p The H value is 8. After mixing evenly, the ethanol and part of the water in the system are removed by vacuum distillation at 40°C and 0.08MPa pressure, so that the styrene-itaconic acid copolymer is deposited and coated on the surface of the iron oxide red pigment , 77 grams of polymer-coated iron oxide red pigment concentrates were obtained.

[0056] Add 2 grams of Tween80, 10 grams of tetraethylene glycol, 10 grams of ethylene glycol, 10 grams of propylene glycol, 0.3 grams of polyether defoamer, 0.03 grams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com