Ultrasonic-assisted method for preparing polymer functionalized graphene

An ultrasonic-assisted, polymer technology, applied in the direction of dyeing polymer organic compound treatment, dyeing physical treatment, fibrous filler, etc., can solve the problem of low content of grafted polystyrene, achieve good dispersibility, simple and easy operation , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In the present embodiment, adopt the following steps to prepare PVA functionalized graphene:

[0033] (1) PVA is dissolved in deionized water, mechanically stirred, and obtaining concentration is the PVA aqueous solution of 50g / L;

[0034] (2) measure this PVA aqueous solution of 50ml in container, then add 5mg graphene, continue to stir for 1 hour, obtain the mixed aqueous solution of PVA and graphene;

[0035] (3) Put the mixed aqueous solution of PVA and graphene in the ultrasonic equipment, discharge the air in the container with high-purity nitrogen, turn on the ultrasonic, set the power to 200W, control the temperature at 20°C, the frequency is 15kHz, and the ultrasonic treatment time For 2 hours, the ultrasonic treatment product was obtained;

[0036] (4) After filtering and washing the ultrasonically treated product with a solvent to remove free PVA, obtain PVA functionalized graphene after drying.

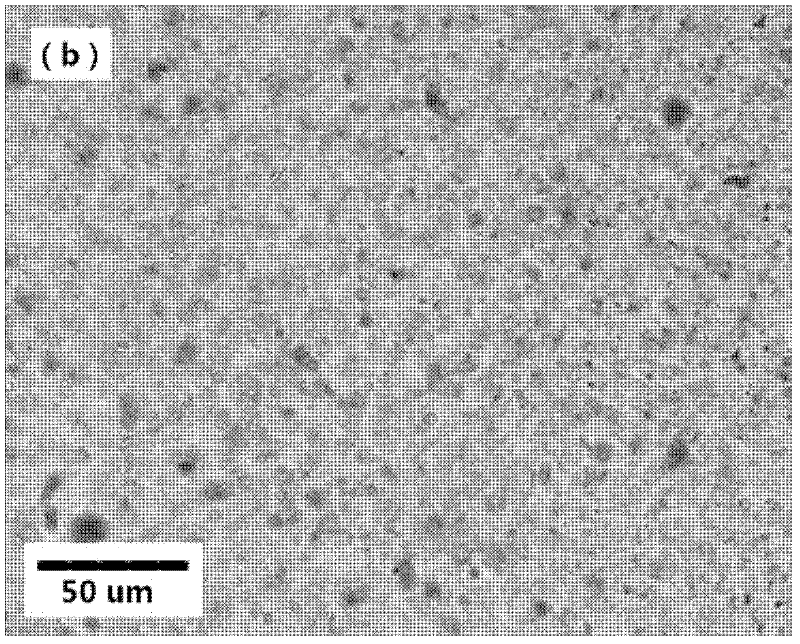

[0037] A solubility experiment was performed on the PVA func...

Embodiment 2

[0048] In the present embodiment, adopt the following steps to prepare PVA functionalized graphene:

[0049] (1) is exactly the same as the step (1) in embodiment 1, obtains the PVA aqueous solution that concentration is 50g / L;

[0050] (2) exactly the same as step (2) in embodiment 1, obtain the mixed aqueous solution of PVA and graphene;

[0051] (3) Put the mixed aqueous solution of PVA and graphene in the ultrasonic equipment, use high-purity nitrogen to discharge the air in the container, turn on the ultrasonic, set the power to 500W, control the temperature at 60°C, the frequency is 18kHz, and the ultrasonic treatment time For 5 hours, the ultrasonic treatment product was obtained;

[0052] (4) is exactly the same as step (2) in embodiment 1, obtains the graphene of PVA functionalization.

[0053] Solubility experiments on the PVA unfunctionalized graphene prepared above show that the PVA functionalized graphene can be uniformly dispersed in water to form a black dispe...

Embodiment 3

[0057] In the present embodiment, adopt the following steps to prepare PVA functionalized graphene:

[0058] (1) is exactly the same as the step (1) in embodiment 1, obtains the PVA aqueous solution that concentration is 50g / L;

[0059] (2) exactly the same as step (2) in embodiment 1, obtain the mixed aqueous solution of PVA and graphene;

[0060] (3) Put the mixed aqueous solution of PVA and graphene in the ultrasonic equipment, use high-purity nitrogen to discharge the air in the container, turn on the ultrasonic, set the power to 1000W, control the temperature at 80°C, the frequency is 27kHz, and the ultrasonic treatment time For 8 hours, the ultrasonic treatment product was obtained;

[0061] (4) is exactly the same as step (2) in embodiment 1, obtains the graphene of PVA functionalization.

[0062] Solubility experiments on the PVA unfunctionalized graphene prepared above show that the PVA functionalized graphene can be uniformly dispersed in water to form a black disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com