Method for preparing spheroid manganous-manganic oxide from manganese sulfate solution

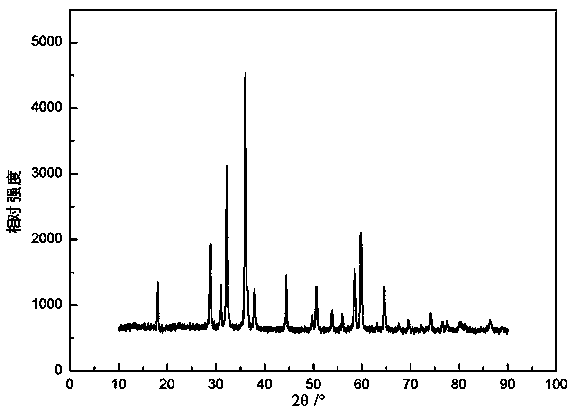

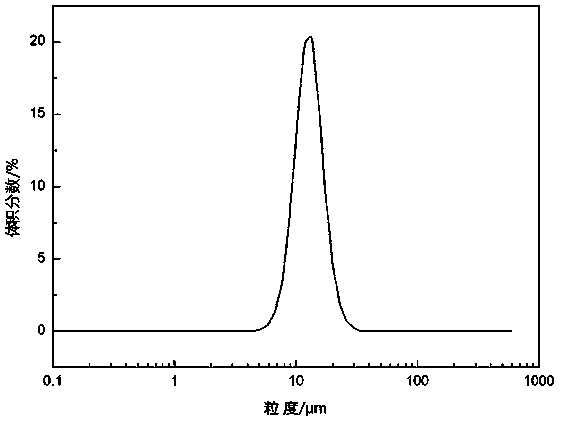

A technology of manganese sulfate solution and manganese tetraoxide, which is applied in the direction of manganese oxide/manganese hydroxide, can solve the problems of large specific surface area of manganese tetraoxide, easy formation of basic manganese sulfate, irregular shape, etc., and achieve production The effect of low cost, low specific surface area and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Add 110g of electrolytic manganese metal flakes and 2000mL of pure water into the dissolution tank, add 110mL of industrial concentrated sulfuric acid with a mass percentage of 98% to the dissolution tank for reaction, and after the dissolution of the manganese flakes is completed, use manganese powder to adjust the pH value of the solution to 3.0 ~4.0, add 5mL hydrogen peroxide, stir for 30min, then add 0.5g ammonium sulfide, continue stirring for 30min, and finally filter to obtain manganese sulfate solution;

[0036] (2) Prepare 2000mL of 2.5mol / L ammonia water and 200mL of 15g / L cyclopentasiloxane solution with deionized water;

[0037] (3) Add deionized water into the reaction kettle as the bottom liquid, the volume of deionized water is just enough to submerge the stirring paddle, and the water bath is heated to 70°C; under the stirring condition, the stirring speed is 300r / min, and the above-mentioned The manganese sulfate solution, ammonia water and cyclopen...

Embodiment 2

[0041] (1) Add 220g of electrolytic manganese metal flakes and 2000mL of deionized water into the dissolving tank, add 220mL of industrial concentrated sulfuric acid with a mass percentage of 98% to the dissolving tank for reaction, and adjust the pH of the solution to 3.5-4.5, add 10mL hydrogen peroxide, stir for 30min, then add 1.0g ammonium sulfide, continue stirring for 30min, and finally filter to obtain manganese sulfate solution;

[0042] (2) Prepare 2000mL of 5.0mol / L ammonia water and 200mL of 20g / L cetyltrimethylammonium bromide solution with deionized water;

[0043] (3) Add deionized water into the reaction kettle as the bottom liquid. The volume of deionized water just submerges the stirring paddle, and the water bath is heated to 70°C; under stirring conditions, the stirring speed is 250r / min, and the above-mentioned The manganese sulfate solution that step obtains, ammoniacal liquor and cetyltrimethylammonium bromide solution are added in the reactor, and mangan...

Embodiment 3

[0047] (1) Add 275g of electrolytic manganese metal flakes and 2000mL of deionized water into the dissolving tank, add 272mL of industrial concentrated sulfuric acid with a mass percentage of 98% to the dissolving tank for reaction, and adjust the pH of the solution to 4.0~5.0, add 15mL hydrogen peroxide, stir for 30min, then add 1.5g sodium thiocarba, continue stirring for 30min, and finally filter to obtain manganese sulfate solution;

[0048] (2) Prepare 2000mL of 6mol / L ammonia water and 200mL of 5g / L ethyl acetate solution with deionized water;

[0049] (3) Add deionized water into the reaction kettle as the bottom liquid, the volume of deionized water is just enough to cover the stirring paddle, and the water bath is heated to 80°C; under the stirring condition, the stirring speed is 300r / min, and the above-mentioned The manganese sulfate solution that step obtains, ammoniacal liquor and ethyl acetate solution are added in the reactor, and manganese sulfate solution feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com