Preparation method of carbon reinforced metal/metal oxide composite powder

A composite powder and metal matrix composite technology, which is applied in the field of preparation of carbonaceous reinforced metal/metal oxide composite powder, can solve the problem of affecting the excellent performance of carbonaceous reinforced metal/metal oxide powder, affecting the uniformity and stability of product performance , large specific gravity difference and size difference, etc., to achieve the effect of controllable particle size distribution, high sphericity and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

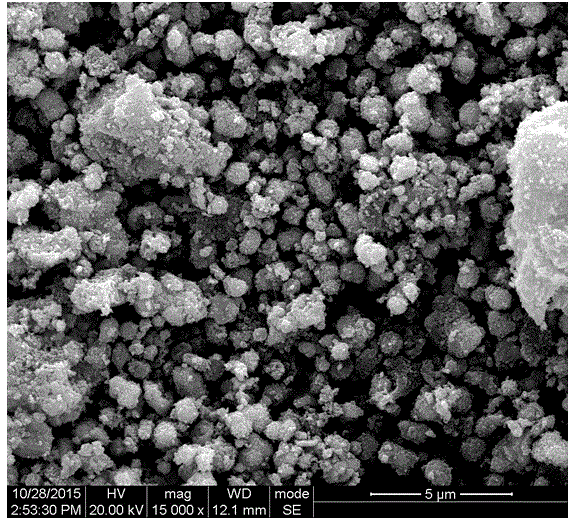

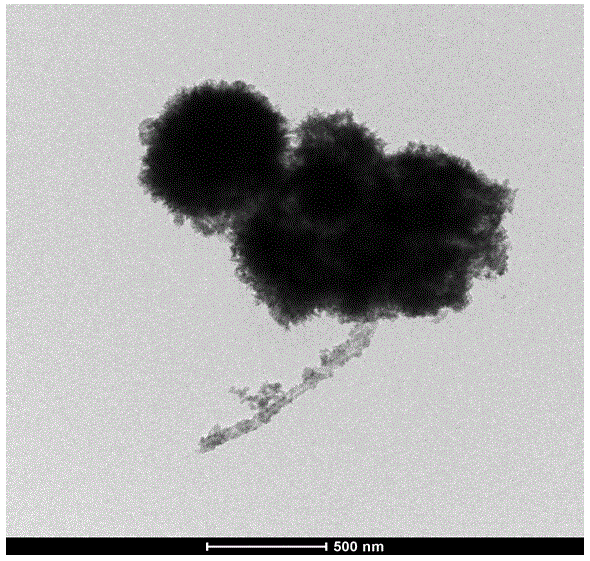

[0028] This example provides the preparation method of carbonaceous reinforced metal / metal oxide composite powder:

[0029] (1) Weigh 50g of copper acetate solution and put it into 5000ml of deionized water to obtain a copper acetate solution, weigh 1g of carbon nanotubes and disperse them into 1000ml of water to obtain a carbon nanotube dispersion;

[0030] (2) Fully stir the copper acetate solution and the carbon nanotube dispersion prepared in step (1) and mix them evenly to obtain a precursor solution. Pour the precursor solution into the storage box of the ultrasonic atomization device and connect it to the At the outlet and the inlet of the high-temperature chamber (which has been heated up to 450°C by resistance heating and kept at a constant temperature), turn on the atomization device and start atomization;

[0031] (3) Turn on the dust collection system for collection, and collect the composite powder produced by pyrolysis through cyclone dust collection to obtain ca...

Embodiment 2

[0033] This example provides the preparation method of carbonaceous reinforced metal / metal oxide composite powder:

[0034] (1) Weigh 100g of copper nitrate solution and put it into 1000ml of deionized water to obtain copper nitrate solution, weigh 1g of graphene and disperse it into 800ml of water to obtain graphene dispersion;

[0035] (2) Fully stir the copper nitrate solution and the graphene dispersion prepared in step (1) and mix them evenly to obtain a precursor solution, pour the precursor solution into the storage box of the ultrasonic atomization device, and connect the outlet of the atomization device and the inlet of the high-temperature chamber (which has been heated up to 600°C by induction heating and kept at a constant temperature), turn on the atomization device and start atomization;

[0036] (3) Turn on the dust collection system for collection, and collect the composite powder produced by pyrolysis through bag dust collection to obtain graphene-enhanced cop...

Embodiment 3

[0038] This example provides the preparation method of carbonaceous reinforced metal / metal oxide composite powder:

[0039] (1) Weigh 50g of cobalt chloride solution and put it into 2000ml of deionized water to obtain a cobalt chloride solution, weigh 1g of fullerene and disperse it into 1000ml of water to obtain a fullerene dispersion;

[0040] (2) Fully stir the cobalt chloride solution and fullerene dispersion prepared in step (1) and mix them evenly to obtain a precursor solution, pour the precursor solution into the storage box of the ultrasonic atomization device, and connect the atomization device At the outlet of the high-temperature chamber (which has been heated to 550°C by microwave heating and kept at a constant temperature) at the inlet, turn on the atomization device and start atomization;

[0041] (3) Turn on the dust collection system for collection, and collect the composite powder produced by pyrolysis through electrostatic dust collection to obtain fullerene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com