Method for preparing Nano silver grain, and prepared Nano silver grain

A technology of silver nanoparticles and silver nitrate, applied in botany equipment and methods, chemical instruments and methods, dyeing polymer organic compound treatment, etc., can solve the problems of low solubility of silver nanoparticles, limited use of silver nanoparticles, insolubility, etc. , to achieve good water solubility and biocompatibility, no toxic side effects, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

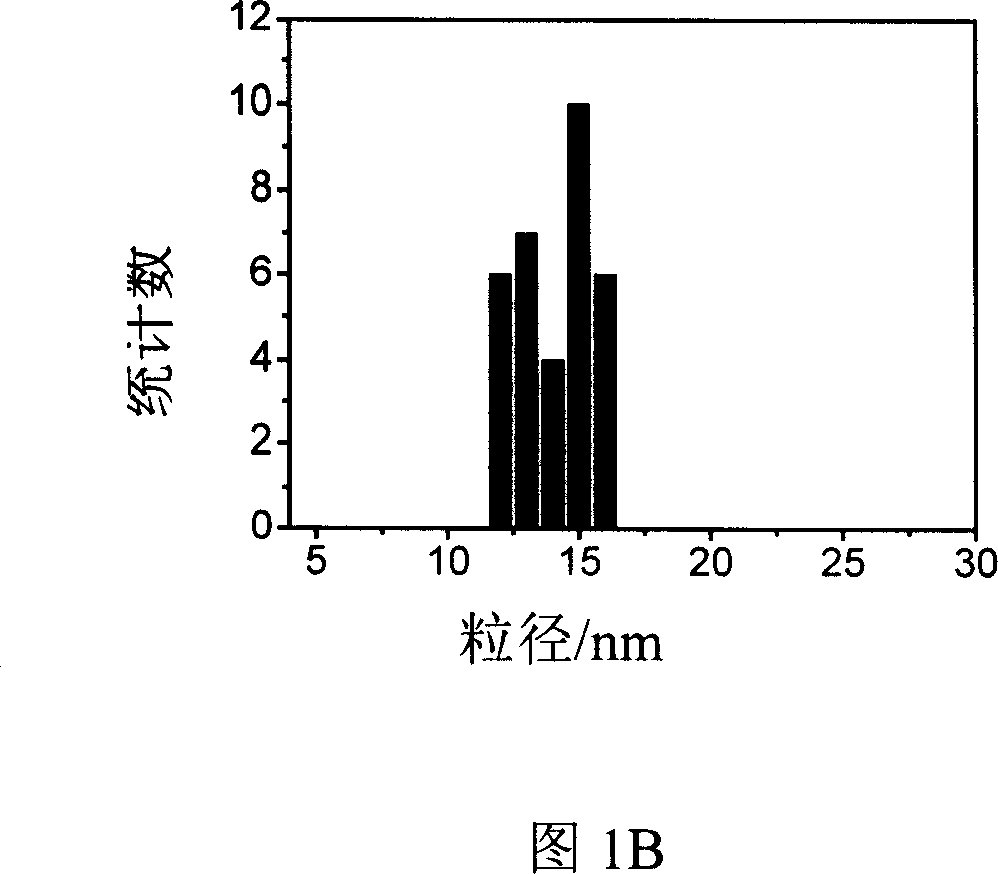

[0037] Dissolve the above-mentioned chitosan with a deacetylation degree ≥ 70% and an average molecular weight of about 20,000 in 0.02% acetic acid, and then mix the solution with silver nitrate solution to obtain a mixed solution, which contains 0.005wt% chitosan sugar and 2.0 x 10 -3 mol.L -1 of silver nitrate. The mixed solution was adjusted to pH 3.0 with acetic acid; 60 The Co source was irradiated, and the irradiation dose was 10kGy to obtain a brownish-yellow solution; the solution was dropped on a copper grid to dry, and then scanned with a transmission electron microscope. As shown, the particle size distribution is shown in Fig. 1B.

[0038] The result shows: as can be seen from Fig. 1A, the particle diameter of the silver nano-particle that preparation method of the present invention makes is relatively uniform, and Fig. 1B also can prove that particle diameter is uniformly distributed, and average particle diameter is 16nm.

Embodiment 2

[0040] Dissolve the above-mentioned chitosan with a deacetylation degree ≥ 70% and an average molecular weight of about 20,000 in 0.01% acetic acid, and then mix the solution with silver nitrate solution to obtain a mixed solution, which contains 0.005wt% chitosan sugar and 1.0 x 10 -3 mol.L -1 silver nitrate, the mixed solution was adjusted to pH 3.0 with acetic acid; 60The Co source was irradiated, and the irradiation dose was 10kGy to obtain a yellow solution; the solution was dropped on a copper grid to dry, and then scanned with a transmission electron microscope. The result is shown in Figure 2A (magnified by 40,000 times, and the scale bar in the figure is 50nm). , the particle size distribution is shown in Fig. 2B.

[0041] The result shows: as can be seen from Fig. 2A, the particle diameter of the silver nanoparticle that preparation method of the present invention makes is more uniform, Fig. 2B also can prove that particle diameter is uniform distribution, and the ...

Embodiment 3

[0043] Dissolve the above-mentioned chitosan with a deacetylation degree ≥ 70% and an average molecular weight of about 15,000 in 0.03% acetic acid, and then mix the solution with silver nitrate solution to obtain a mixed solution, which contains 0.005wt% chitosan sugar and 5.0 x 10 -4 mol.L -1 silver nitrate, the mixed solution was adjusted to pH 3.0 with acetic acid; 60 The Co source was irradiated, and the irradiation dose was 10kGy to obtain a bright yellow solution; the solution was dropped on a copper grid to dry, and then scanned with a transmission electron microscope. As shown, the particle size distribution is shown in Fig. 3B.

[0044] The result shows: as can be seen from Fig. 3A, the particle diameter of the silver nanoparticle that preparation method of the present invention makes is relatively uniform, and Fig. 3B also can prove that particle diameter is uniform distribution, and the average particle diameter of silver nanoparticle is 8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com