Ultrasonic micro-reactor preparation method of nano-drug

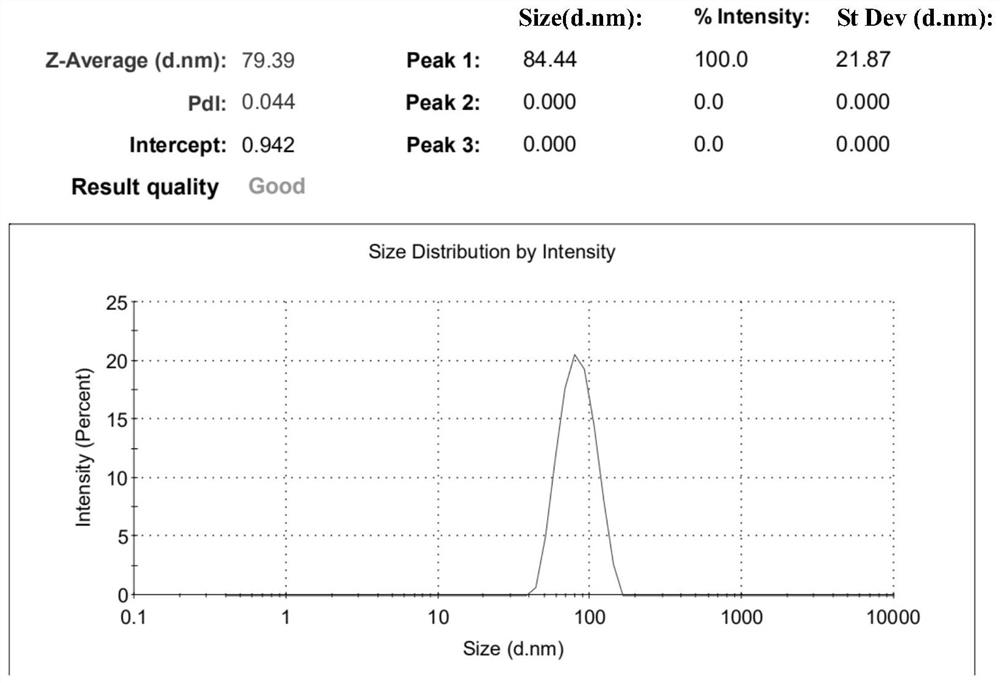

A micro-reactor and nano-drug technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc. Good monodispersity, preventing clogging of channels, and small average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0029] Embodiment 1-4, preparation of lipid nanoparticle nanomedicine (siRNA)

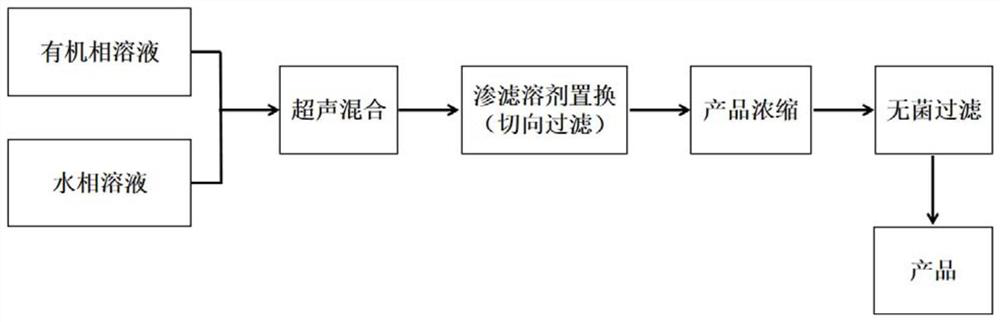

[0030] The experimental procedure follows figure 2 The process flow shown. Among them, the nano-drug precursors are selected from DOTAP ((2,3-dioleoyl-propyl)-trimethylamine, cationic lipid), DSPC (distearoylphosphatidylcholine, structural lipid), cholesterol, PEG2000-DMG (1,2-Dimyristoyl-rac-glycerol-3-methoxypolyethylene glycol 2000, modified with polyethylene glycol lipid) system as a lipid substance, wherein the content of each component DOTAP: DSPC: cholesterol : PEG2000-DMG=50:10:38.5:1.5 (molar ratio); wherein DOTAP, DSPC, and cholesterol are analytically pure and purchased from AVT, and PEG2000-DMG is purchased from Avanti. Lipids were dissolved in absolute ethanol as an organic phase solution, and the aqueous phase solution was double-stranded siRNA (19nt) (purchased from General Biology) dissolved in citrate buffer (10mM, pH=4.0); siRNA and lipid The molar ratio of the species is 1:8,...

Embodiment 5-6

[0031] Embodiment 5-6, polymer nanoparticle nano drug preparation

[0032] The experimental procedure follows figure 2 The process flow shown. Among them, the nano drug precursor is selected from mPEG5K-PLGA10K (methyl polyethylene glycol 10k polylactic acid-glycolic acid 5k-block copolymer, purchased from Shanghai Yayi Biotechnology Company), and the active ingredient of the drug is selected from curcumin (purchased from Shanghai Mike Lin Biochemical Technology Co., Ltd.), wherein mPEG5K-PLGA10K and curcumin are dissolved in dimethylformamide as an organic phase solution, the molar ratio of curcumin and mPEG5K-PLGA10K is 1:5, and the aqueous phase solution is a phosphate buffer solution (20mM , pH=7.4), the flow ratio of the organic phase solution to the aqueous phase solution is 1:3, and the residence time in the ultrasonic microreactor at room temperature is 0.5s. The buffer solution is a phosphate buffer solution (20mM, pH=7.4), the mixed product is diluted 10 times in ...

Embodiment 7-8

[0033] Embodiment 7-8, preparation of lipid nanoparticle nanomedicine (mRNA)

[0034] The experimental procedure follows figure 2 The process flow shown. Among them, the nano-drug precursors are selected from DOTAP ((2,3-dioleoyl-propyl)-trimethylamine, cationic lipid), DSPC (distearoylphosphatidylcholine, structural lipid), cholesterol, PEG2000-DMG (1,2-Dimyristoyl-rac-glycerol-3-methoxypolyethylene glycol 2000, modified with polyethylene glycol lipid) system as a lipid substance, wherein the content of each component DOTAP: DSPC: cholesterol : PEG2000-DMG=50:10:38.5:1.5 (molar ratio); wherein DOTAP, DSPC, and cholesterol are analytically pure and purchased from AVT, and PEG2000-DMG is purchased from Avanti. Lipids were dissolved in absolute ethanol as an organic phase solution, and the aqueous phase solution was ARCA EGFP mRNA (mRNA of enhanced green fluorescent protein modified with ARCA) (purchased from Blue Que Bio) dissolved in citrate buffer ( 10mM, pH=4.0); the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com