Nano-material modified chlorinated polyethylene cable sheath material

A technology of chlorinated polyethylene and cable sheathing materials, which is applied in the direction of rubber insulators and organic insulators, and can solve the problems of mechanical properties, wear resistance, low temperature and other properties that cannot meet the requirements of neoprene and chlorinated polyethylene. Achieve compact structure, small average particle size, and improve material toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

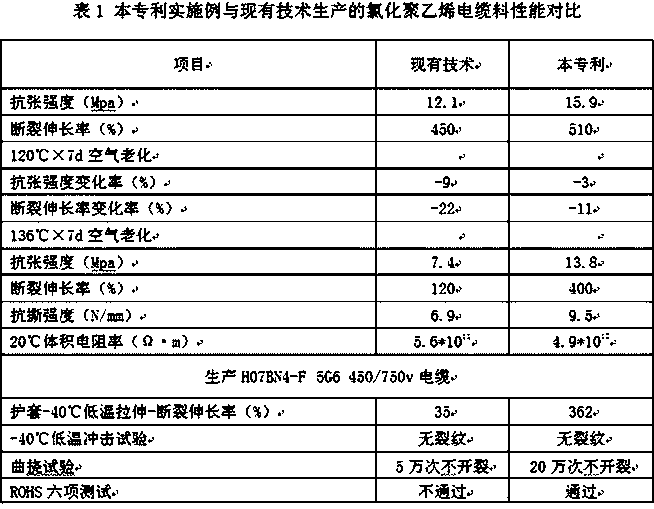

Examples

Embodiment Construction

[0014] The present invention will be further described below by example.

[0015] A kind of nanometer material modified chlorinated polyethylene cable sheathing material, its component and content are as follows:

[0016] 100 parts of chlorinated polyethylene rubber, 1-3 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 10-15 parts of magnesium oxide, 3-6 parts of calcium stearate, Ca -5-10 parts of Zn stabilizer, 1-2 parts of dispersant, 1-2 parts of coupling agent, 1-3 parts of antimony trioxide, 20-30 parts of precipitated white carbon black, 40-60 parts of flake talcum powder 10-15 parts of nano-reinforced powder, 10-15 parts of dioctyl terephthalate, 5-10 parts of dioctyl adipate, 3-4 parts of dicumyl peroxide, triallyl isocyanate 2-3 parts of uric acid ester.

[0017] The dispersant is polyethylene wax, stearic acid, zinc stearate, and surface treatment agent, or a mixture of two or more, the purpose of which is to help disperse the nano-reinforced powder.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com