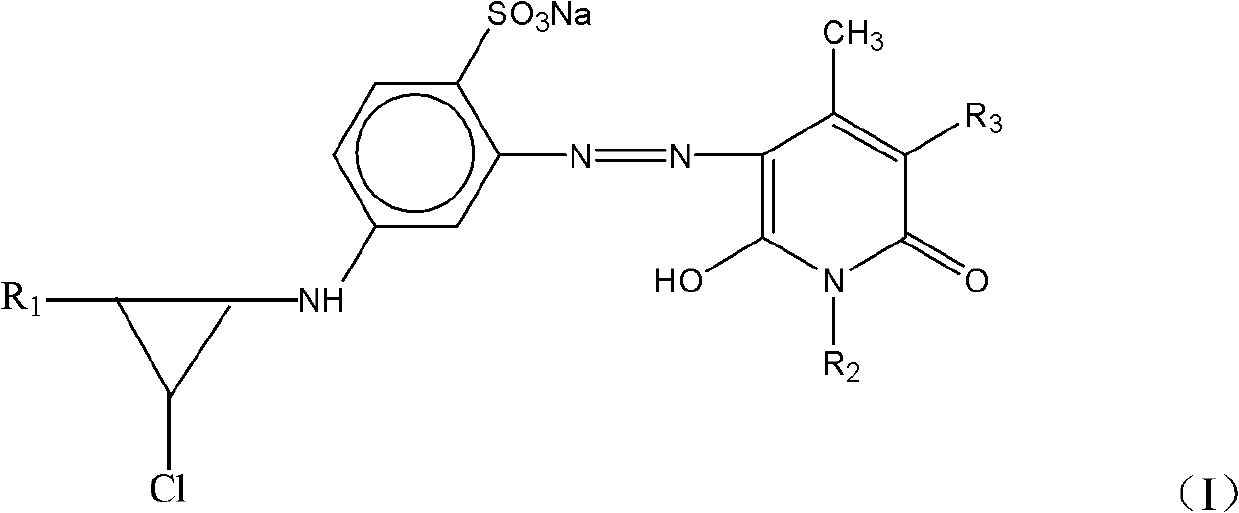

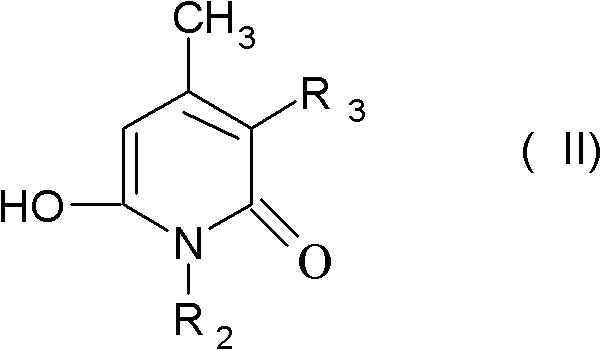

Yellow dye, as well as preparation method and application thereof

A technology of yellow dyes and dyes, applied in dyeing methods, azo dyes, organic dyes, etc., can solve the problems of large average particle size of dyes, low coloring rate, high salt content, etc., and achieve bright color and low salt content , The effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

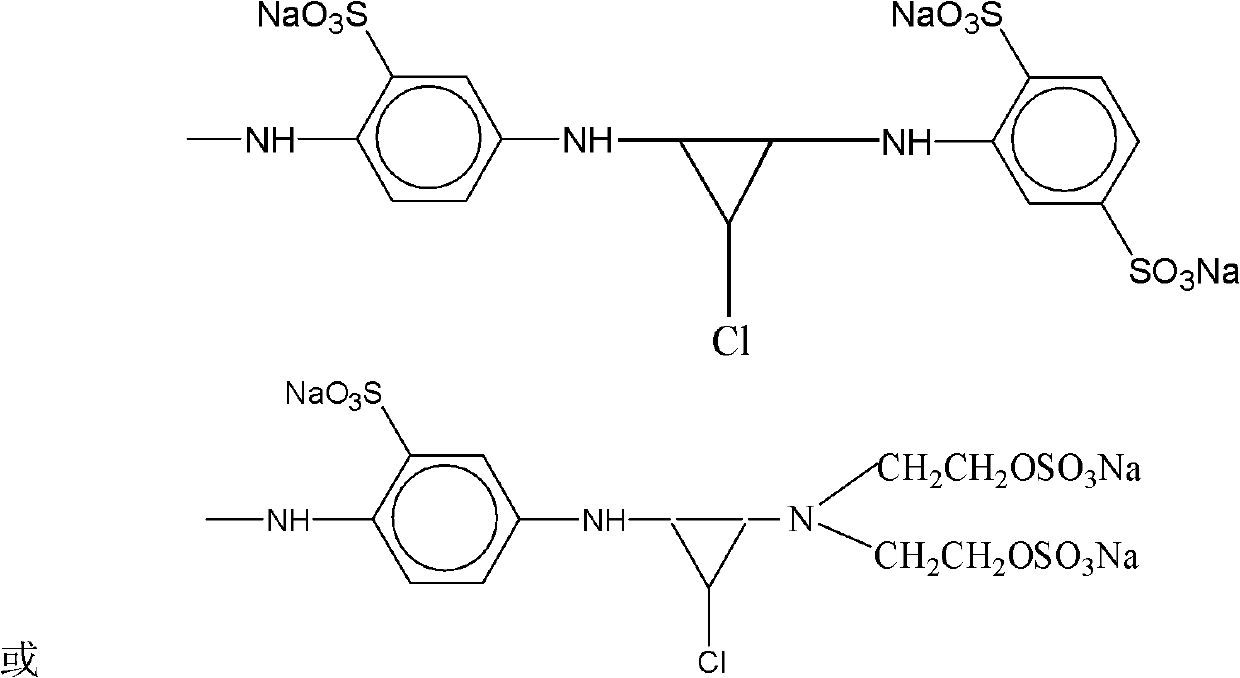

Method used

Image

Examples

Embodiment 1

[0043] a. Preparation of condensate

[0044] a-1-1, the preparation of the shrinkage

[0045] Add a small amount of bottom water to the beaker, 25.3 grams of 100% aniline-2,5 disulfonic acid, and use NaHCO 3 Neutralize pH=6.0-7.0, for later use;

[0046] Take another beaker, add a small amount of ice water and ice grinding aid in the beaker, then add 18.5 grams of 100% cyanuric chloride, and mix the materials evenly. Pour aniline-2,5 disulfonic acid solution, and react for 4 hours at T=0-5°C, pH=4.0-5.0 to obtain a condensate, add 2,5-diaminobenzene to the condensate 21.0 grams of sodium sulfonate, adjust T=30-40°C, pH=5.0-6.0, and react for 6 hours. cool down, spare,

[0047] a-1-2. Add a small amount of ice water and ice grinding aid to the beaker, and then add 18.5 grams of cyanuric chloride to mix the materials evenly. Pour into the final condensation solution of a-1-1, T=0-5°C, pH=4.0-5.0, dropwise, then react for 5 hours, add 2,4-diaminobenzenesulfonic acid to the c...

Embodiment 2

[0060] a. Preparation of condensate

[0061] a-1-1. Add a small amount of bottom water and 10.5 g of 100% diethanolamine to a beaker, and neutralize it with 30% HCL to pH=7.0-8.0 to obtain a diethanolamine solution for later use.

[0062] Take another beaker, add a small amount of ice water and ice grinding aid in the beaker, then add 18.5 grams of 100% cyanuric chloride, and mix the materials evenly. Add diethanolamine solution dropwise, and react for 4 hours under the conditions of T=0-5°C and pH=4.0-5.0 to obtain a condensate, and add 21.0 g of sodium 2,5-diaminobenzenesulfonate to the condensate, Adjust T=30-40°C, pH=5.0-6.0, and react for 6 hours. cool down, spare,

[0063] a-1-2. Add a small amount of ice water and ice grinding aid in a beaker, and then add 18.5 grams of 100% cyanuric chloride to mix the materials evenly. Pour the final condensation solution obtained in a-1-1, maintain T=0-5°C, pH=4.0-5.0, then react for 5 hours, add 21.0 grams of sodium 2,4-diaminobe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com