Spherical metal powder and preparation method thereof

A metal powder and spherical technology, which is applied in the field of spherical metal powder and its preparation, can solve the problems of powder dependence on the original powder particle size, difficulty in mass production, difficulty in fine powder agglomeration, powder delivery, etc., to achieve narrow particle size distribution, reliable technology, and product particle size easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

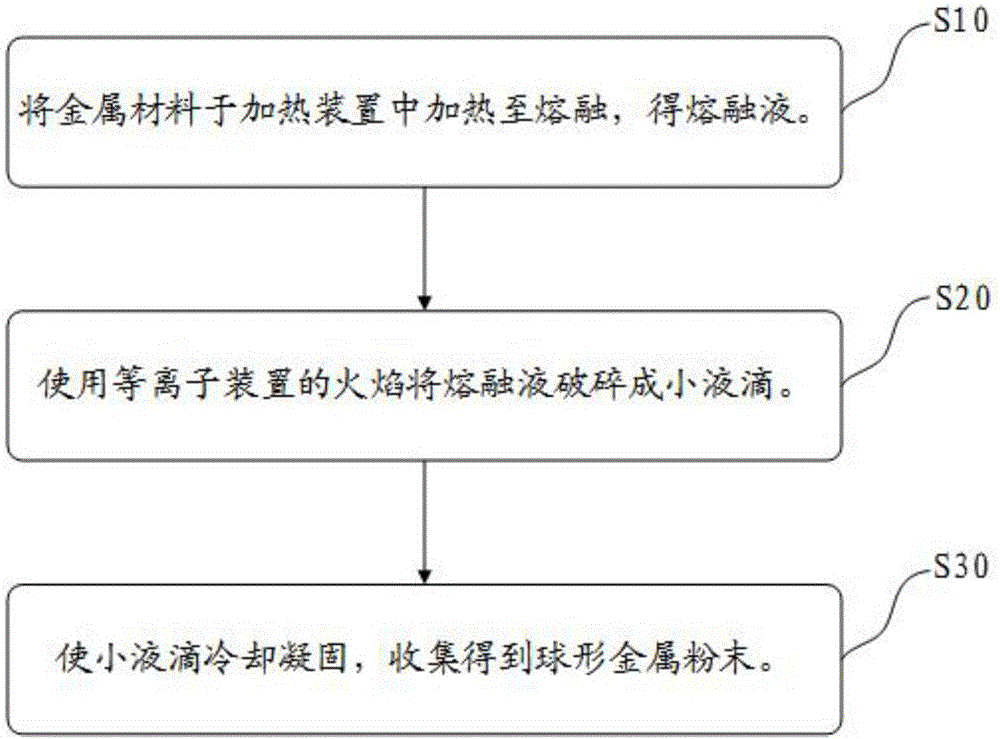

[0042] Such as figure 1 Shown, a kind of preparation method that can prepare the spherical metal powder that particle size is less than 53 μ m and does not contain satellite particle, comprises the following steps:

[0043] S10: heating the metal bar in a heating device until it melts to obtain a molten liquid;

[0044] S20: Using the flame of the plasma device to break the molten liquid into small liquid droplets;

[0045] S30: cooling and solidifying the small droplets, and collecting spherical metal powder.

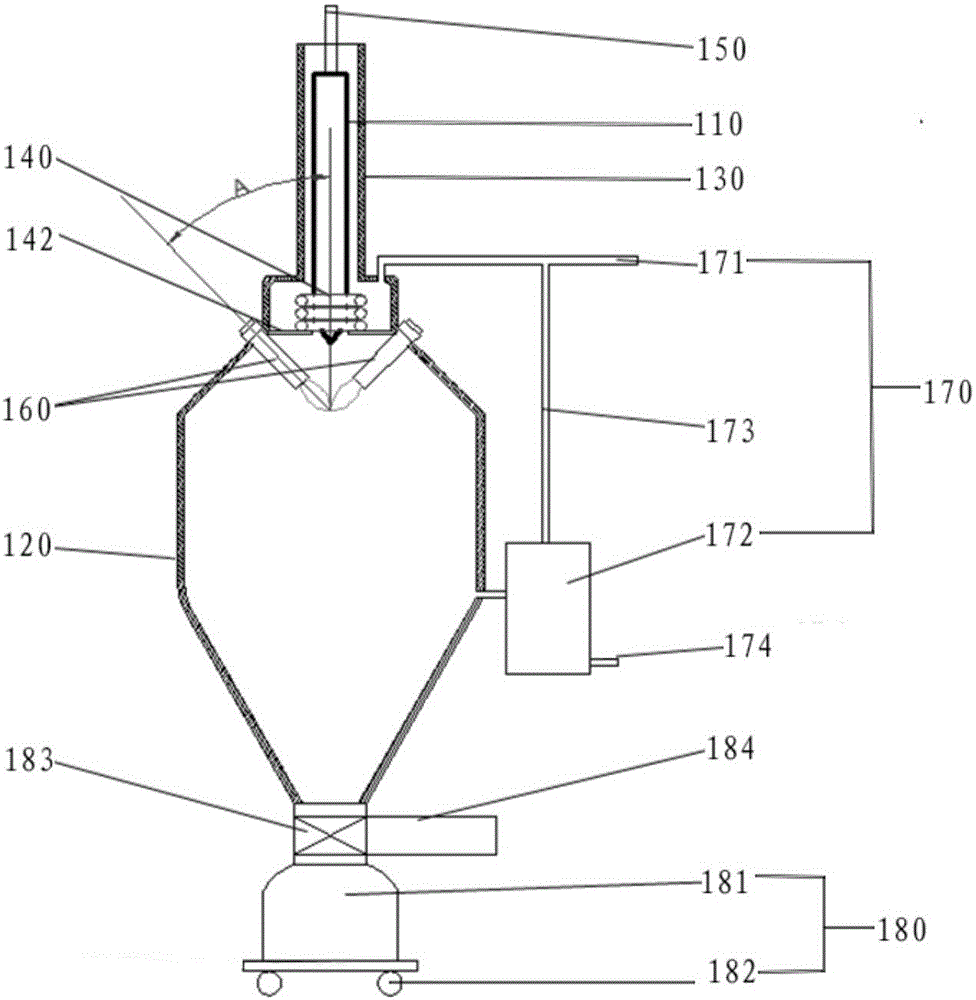

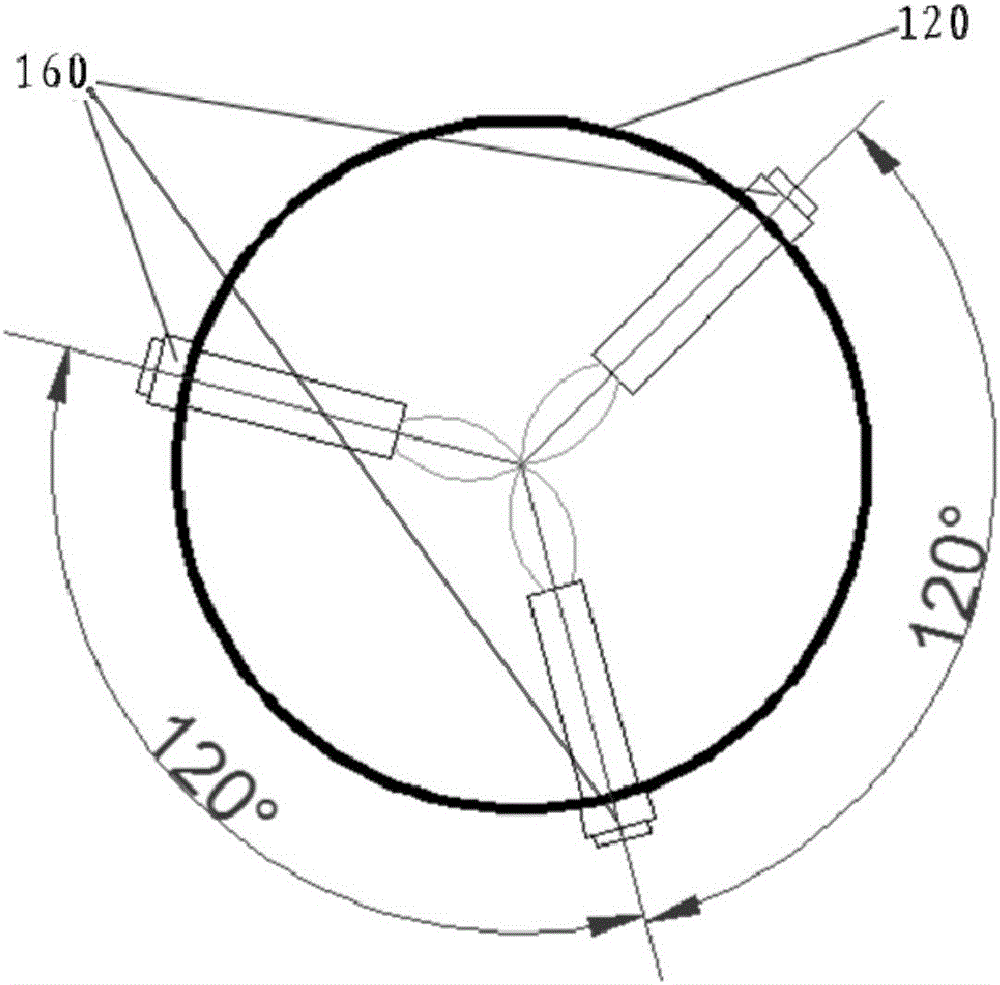

[0046] Such as figure 2 As shown, the spherical metal powder preparation device according to one embodiment of the method of the present application includes a metal rod 110 , an atomizing tower 120 , a tower neck 130 , a heating device 140 , a conveying device 150 and a plasma device 160 .

[0047] Metal rod 110, one end is tapered; atomization tower 120, has an atomization chamber for atomizing metal rod 110, the two ends of the atomization chamber are respective...

Embodiment 1

[0056] This embodiment is a preparation process of industrial pure titanium powder for 3D printing of spherical metal powder. The gas source 171 is filled with inert gas. Turn on the heating device 140 to heat and make the pure titanium rod melt to form a molten liquid, and adjust the angle between the axis of the plasma flame sent by the plasma device 160 and the axis of the metal rod 110 to be 44°, and the top of the plasma flame of the plasma device 160 is conical with the rod. The end distance is 54mm, the molten liquid falls to the plasma flame of the plasma device 160 and is broken into small droplets, the output power of the plasma device is 14-15KW, the working gas is high-purity argon, and the jet velocity is 850-1000m / s. The argon gas pressure in the atomization tower 120 is kept at 0.3-0.5 MPa, and the small droplets after plasma crushing are cooled and solidified in the argon environment, and collected and taken out after cooling to room temperature. Then use an u...

Embodiment 2

[0060] This embodiment is a preparation process of TC4 titanium alloy powder for spherical metal powder 3D printing. The specific operation is as follows: after removing surface impurities and oxides on the special Ti6Al4V rod with a lathe, put it into the conveying device 150, turn on the inert gas Source 171, filled with inert gas. Turn on the heating device 140 to heat the Ti6Al4V rod to melt to form a melt, adjust the angle between the axis of the plasma flame sent by the plasma device 160 and the axis of the metal rod 110 to be 46 °, the top of the plasma flame of the plasma device 160 and the tapered end of the rod The distance is 50mm, the molten liquid falls to the plasma flame of the plasma device 160 and is broken into small droplets, the output power of the plasma device is 14-15KW, the working gas is high-purity argon, and the jet velocity is 850-1000m / s. The argon gas pressure in the atomization tower 120 is kept at 0.3-0.5 MPa, and the small droplets after plasma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com