Method for preparing light temperature-resistance high surface area alumina and aluminiferous composite oxide

A high surface area, alumina technology, applied in alumina/aluminum hydroxide, aluminum compounds, chemical instruments and methods, etc., can solve the problem of high cost, reduce raw material and production costs, facilitate realization, and achieve the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

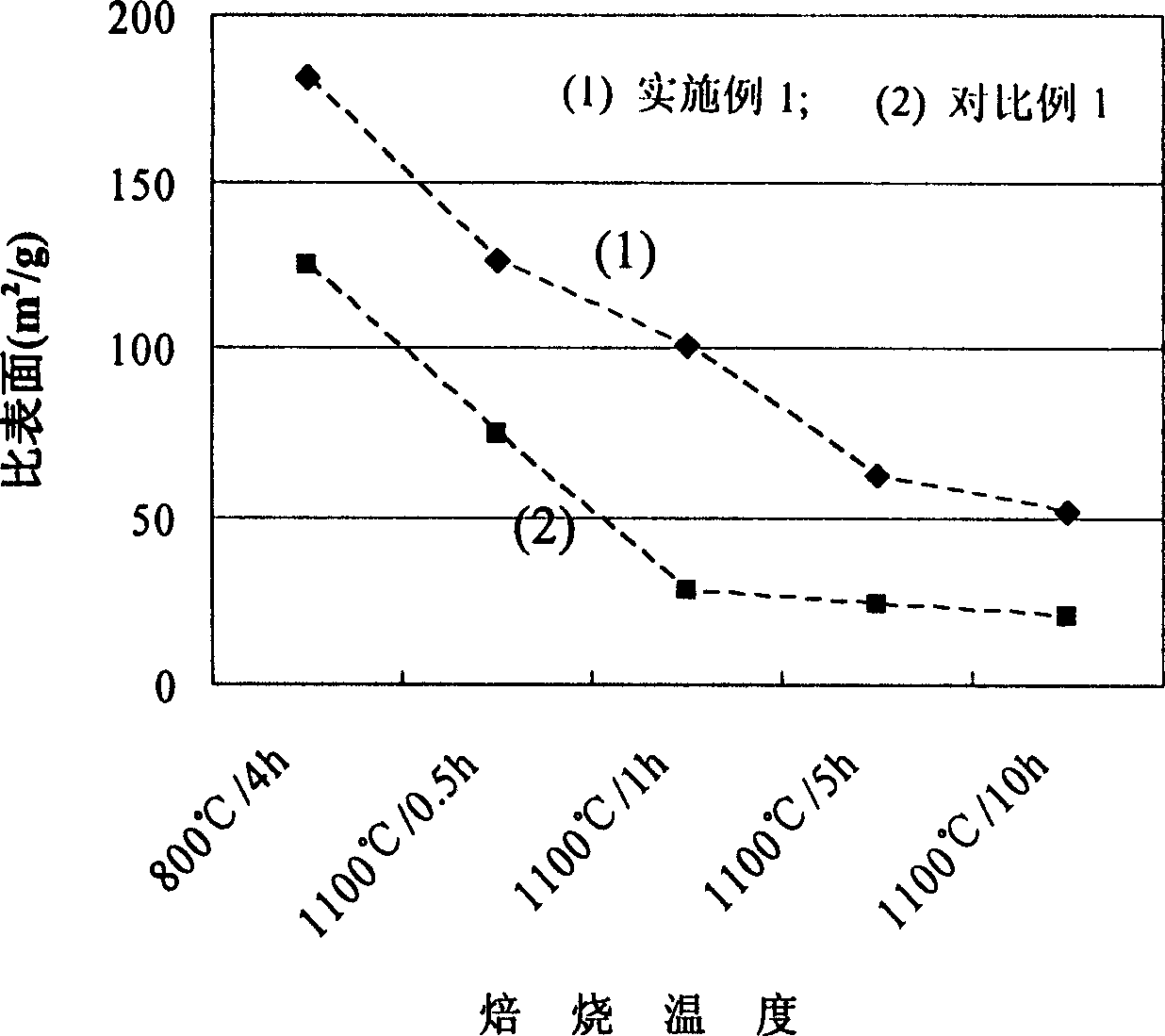

Embodiment 1

[0036] Synthesis of Al by Inverse Microemulsion Method 2 o 3 .

[0037] With polyethylene glycol octyl phenyl ether as surfactant, n-hexanol as co-surfactant, and cyclohexane as oil phase, wherein surfactant / co-surfactant / cyclohexane=5 / 6 / 37( Volume ratio).

[0038] In the preparation process, surfactant, co-surfactant, and cyclohexane are mixed in the above ratio, and after stirring evenly, it is divided into two parts, each part is 430ml, and the nitric acid concentration of 27.3wt% is added dropwise to one of them. Aqueous aluminum solution, the addition is 50ml, stirs while adding dropwise, until clear and transparent, the gained mixture is the inverse microemulsion of aluminum nitrate;

[0039] In the other portion, dropwise add ammoniacal liquor with a concentration of 25-28%, in an amount of 50ml, and stir while adding dropwise, to obtain a light blue clear transparent liquid that is an inverse microemulsion of ammoniacal liquor.

[0040] At room temperature, the rev...

Embodiment 2

[0042] Synthesis of Ba-modified Al by Inverse Microemulsion Method 2 o 3 .

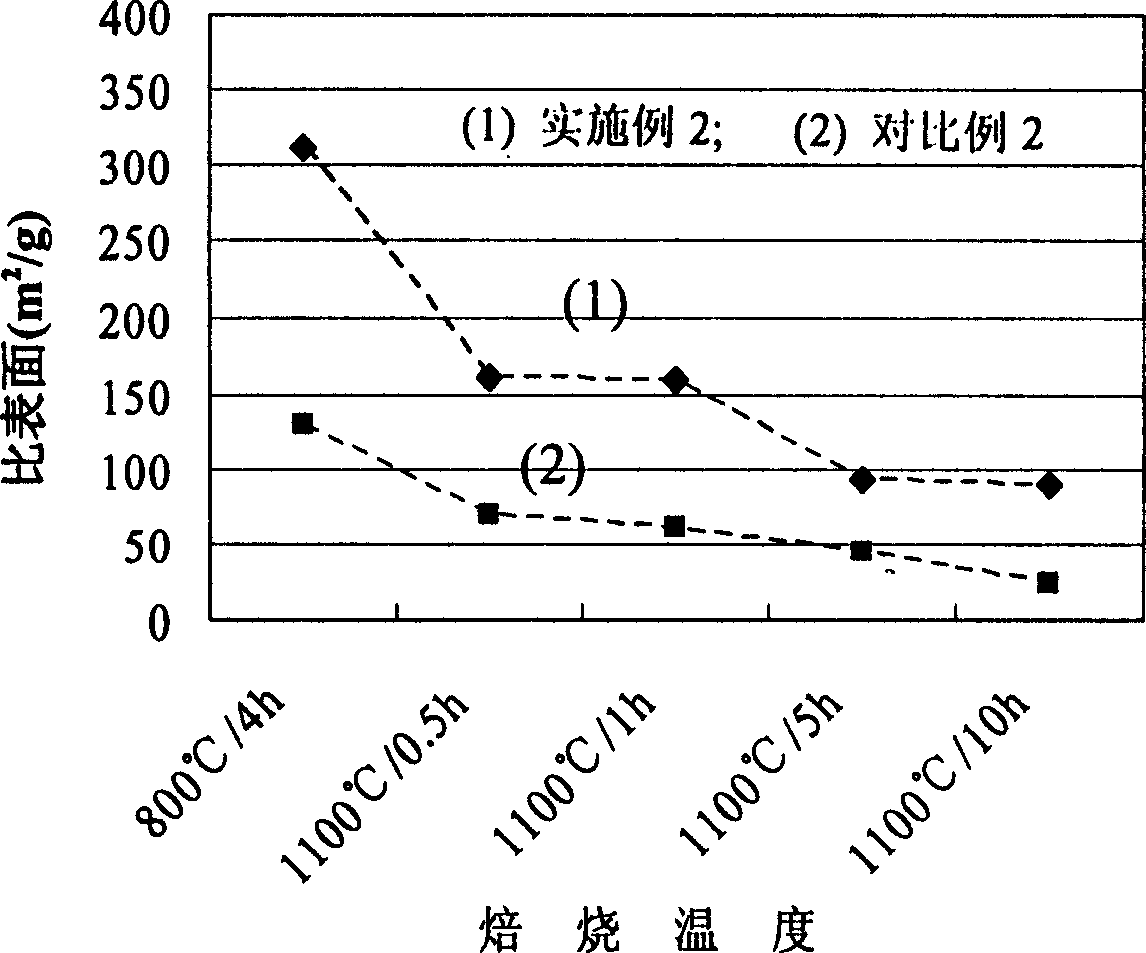

[0043] Adopt the used tensio-active agent of embodiment 1, co-surfactant and oil phase, prepare the inverse microemulsion of aluminum nitrate and ammoniacal liquor in the same ratio, difference is that 0.14g barium nitrate has been added in the aqueous solution of aluminum nitrate. Other synthetic processes are the same as in Example 1. figure 2 (1) is the BET specific surface area of the obtained samples after firing under different conditions. The results showed that the specific surface area was 89.7m after being calcined at 1100°C for 10h. 2 / g, higher than that of pure Al prepared by the same method 2 o 3 specific surface area. Literature (Acta Physicochemical Society, 2001, 17(11): 1036-1039) reported that barium-modified Al 2 o 3 After calcination at 1100℃ for 10h, its surface area is 41m 2 / g; Barium-modified Al prepared by the sol-gel method (Chemical Journal of Chinese Universiti...

Embodiment 3

[0045] Synthesis of silicon-modified Al by inverse microemulsion method 2 o 3 .

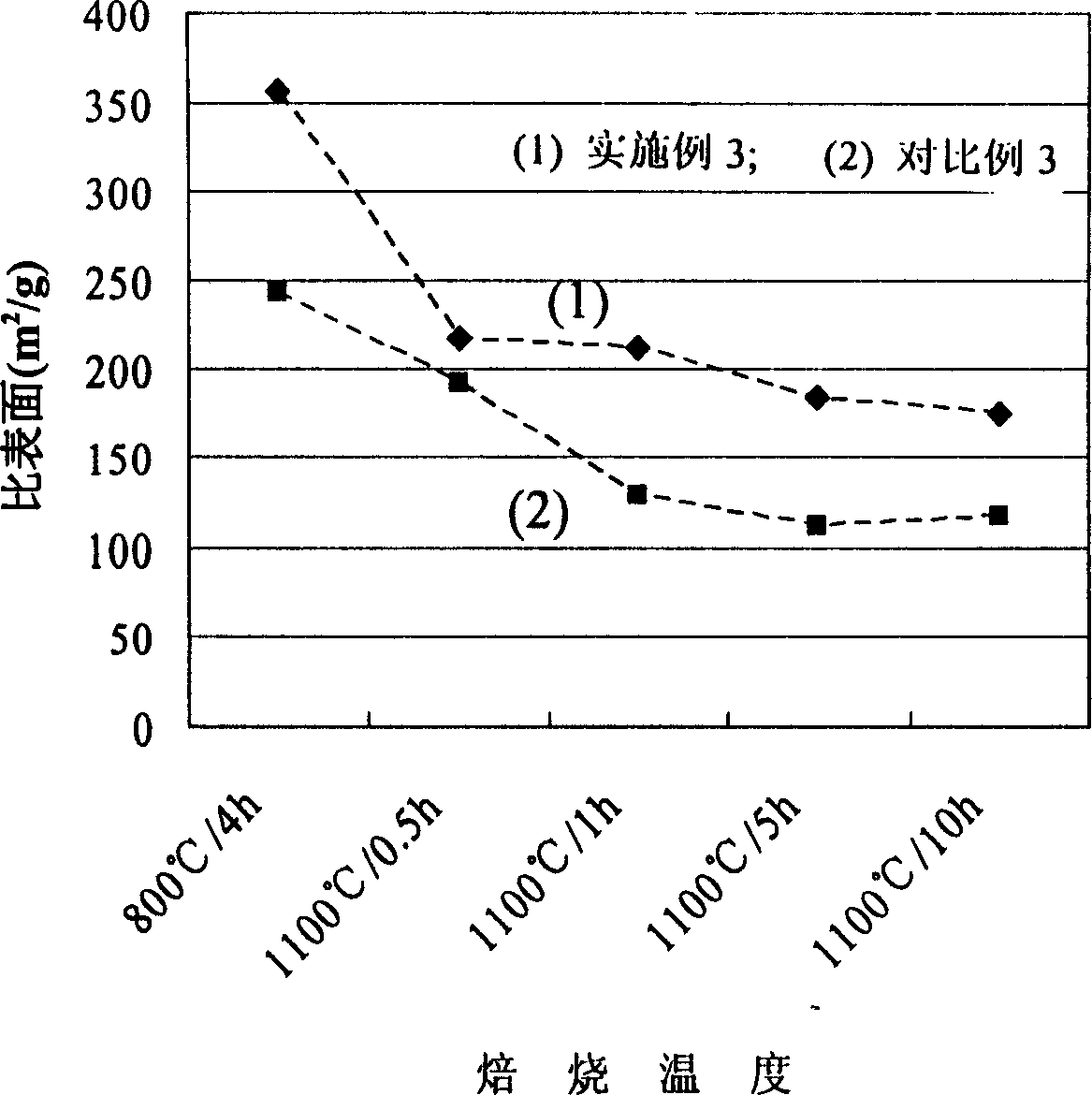

[0046] The surfactant, co-surfactant and oil phase used in Example 1 were used to prepare the inverse microemulsion of aluminum nitrate and ammoniacal liquor in the same proportion, except that 1.3g orthosilicate was added in the aqueous solution of aluminum nitrate ethyl ester. Other synthetic processes are the same as in Example 1. image 3 In (1) is the specific surface area value of the obtained sample after roasting under different conditions. After roasting at 1100°C for 10 hours, the specific surface area can be maintained at 174.9m 2 / g, much higher than that of pure Al prepared by the same method 2 o 3 specific surface area. Silicon-modified Al prepared by sol-gel method 2 o 3 After being treated under the same conditions, its surface area is 116.7m 2 / g (comparative example 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com