Nitrogen-doped mesoporous hollow carbon sphere loaded metal-based nano-catalyst and preparation method thereof

A nano-catalyst and hollow carbon sphere technology, applied in the field of nano-materials, can solve the problems of poor catalytic performance and high surface energy, and achieve the effects of high yield, inhibition of agglomeration, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Step 1, the preparation method of nitrogen-doped mesoporous hollow carbon sphere carrier, the specific steps are:

[0043] Step 1.1 Preparation of the silica hard template: Add tetraethylorthosilicate to the reaction medium of water and ethanol, and use the sol-gel method to synthesize and synthesize nano-silica beads at 30°C.

[0044] In step 1.2, add the nano-silica beads prepared in step 1.1 to tris buffer solution, place in ultrasonic treatment, and the ultrasonic treatment time is 1h, wherein the nano-silica beads are buffered in tris The concentration of the solution is 2-100 mg / mL; then add dopamine hydrochloride to carry out polymerization reaction, at 25 ° C, the polymerization reaction time is 24 hours, the mass ratio of dopamine hydrochloride and nano-silica beads is (0.25-5): 1, The precursor was obtained by centrifugal washing and drying.

[0045] Step 1.3: Put the precursor in step 1.2 into a tube furnace for calcination under a nitrogen atmosphere and ke...

Embodiment 1

[0057] Direct synthesis method Pd@NHCS-600°C (wherein Pd: 2.5wt%, silica: dopamine hydrochloride = 1:1) catalyst preparation: Weigh 500mg of nano-silica pellets and add 50mL tris to buffer The solution was subjected to ultrasonic treatment for 1 hour, then 500 mg of dopamine hydrochloride was added for polymerization and stirred for 30 minutes, 77.8 mg of potassium tetrachloropalladate was added, and stirring was continued for 24 hours. The precursor was obtained by centrifugal washing and drying. The precursor was placed in a tube furnace and fired at 10° / min to 600°C under a nitrogen atmosphere and held for 1 h. The calcined sample was placed in a 5 mol / L sodium hydroxide solution and stirred at 60°C for 6 hours, and the silica template was etched to obtain a metal-based nanocatalyst Pd@NHCS-600°C supported by nitrogen-doped mesoporous hollow carbon spheres.

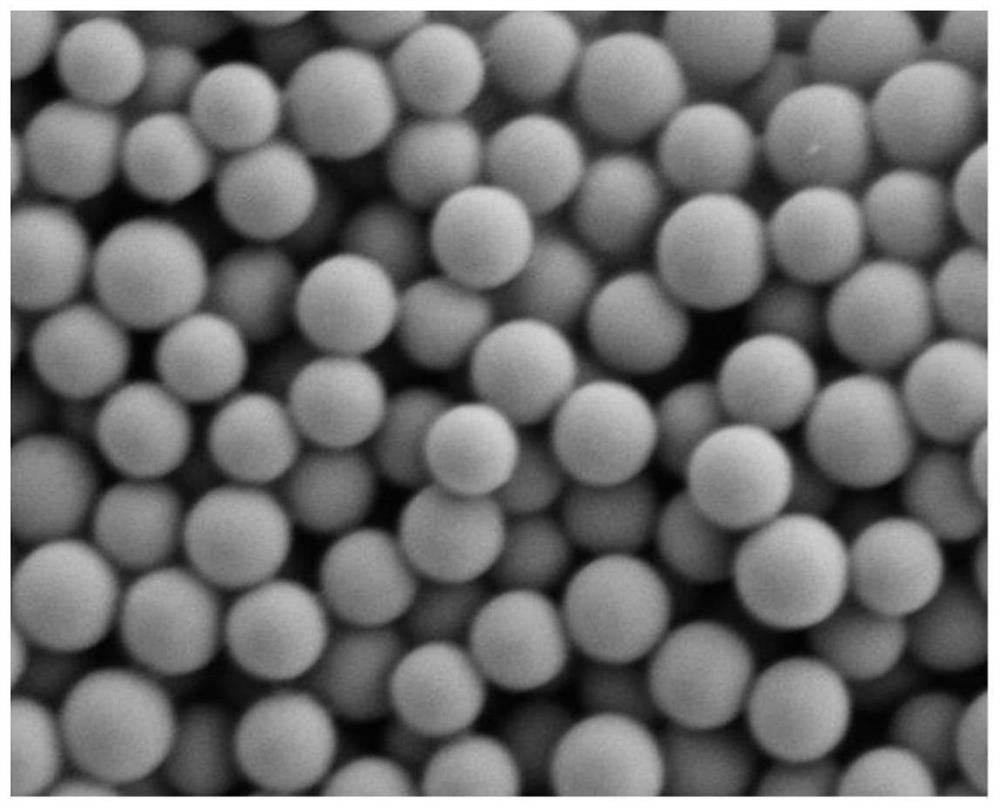

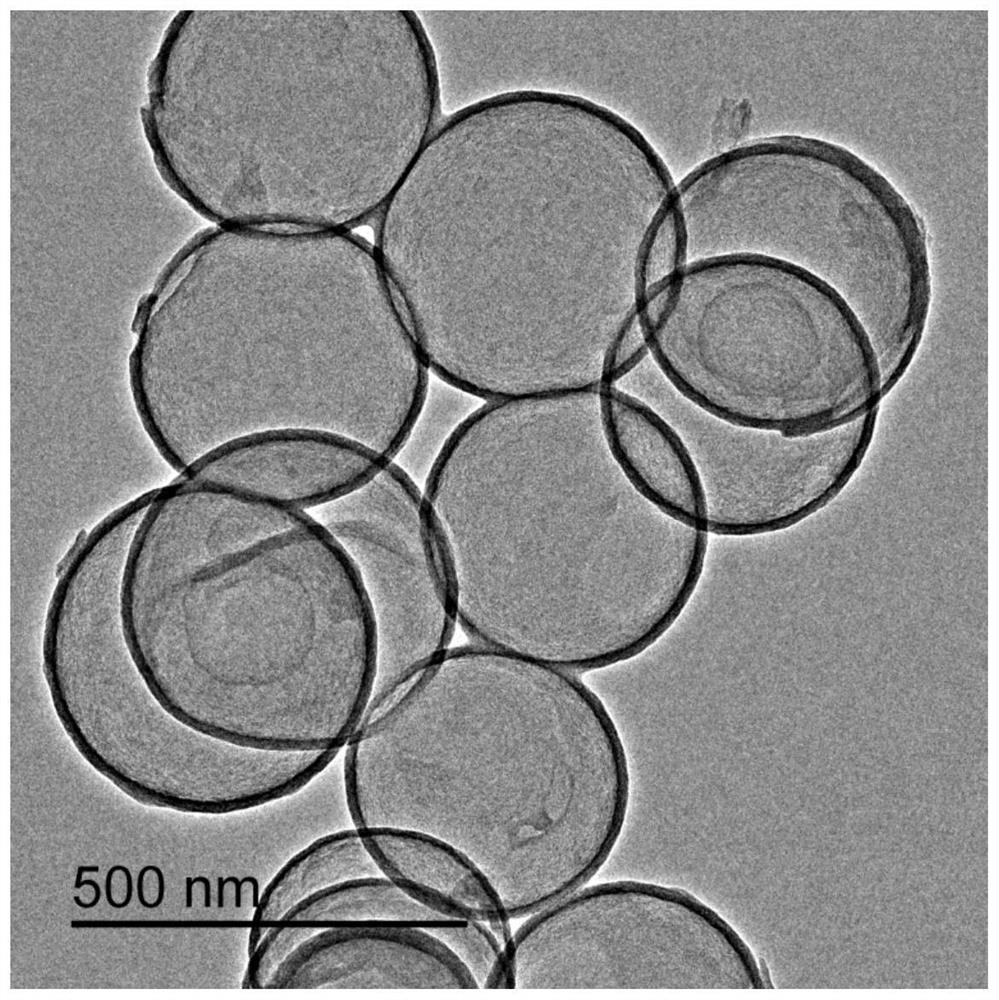

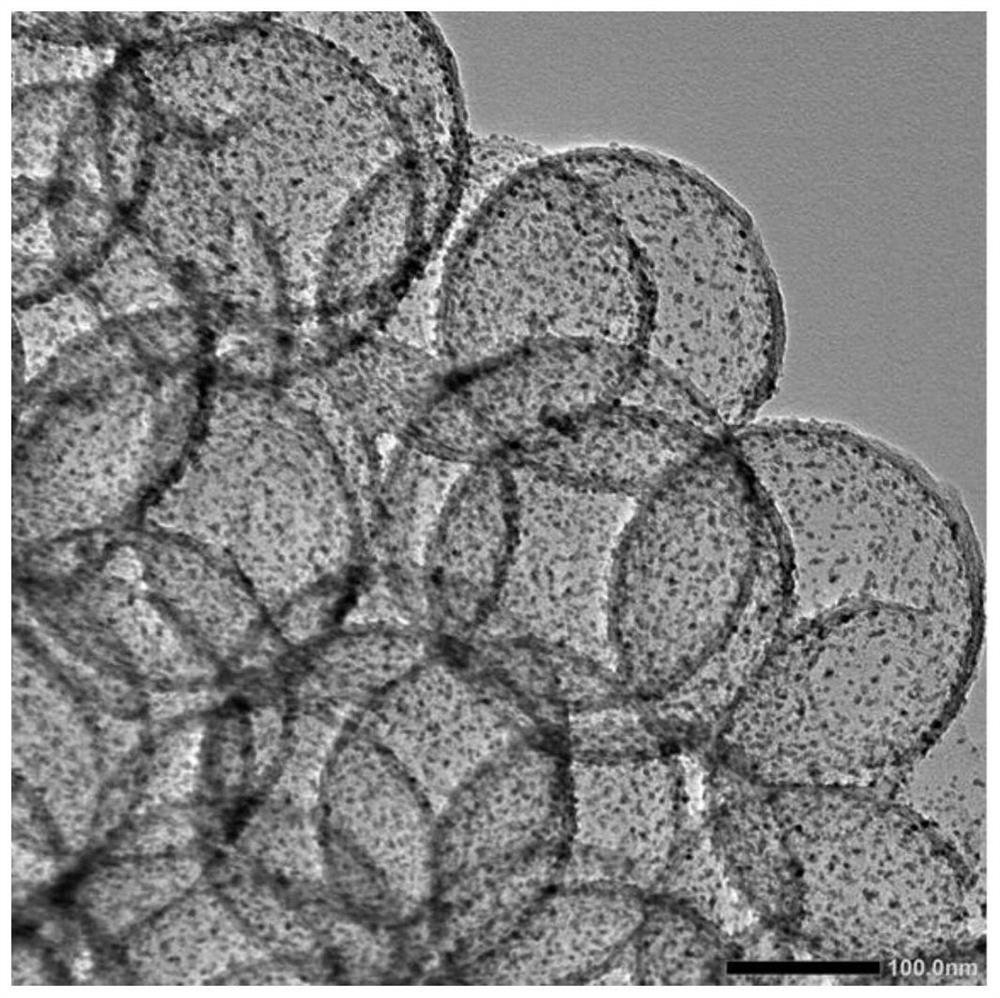

[0058] figure 1 It is a scanning electron microscope photo of a hard template silica ball; from the SEM image, it c...

Embodiment 2

[0061] Direct synthesis method Pd@NHCS-900°C (wherein Pd: 1.5wt%, silica: dopamine hydrochloride = 2:1) catalyst preparation: Weigh 500mg nano-silica pellets and add 50mL Tris buffer The solution was subjected to ultrasonic treatment for 1 hour, then 250 mg of dopamine hydrochloride was added to polymerize and stirred for 30 minutes, 35 mg of potassium tetrachloropalladate was added, the mixture was stirred for 24 hours, and the precursor was obtained by centrifugal washing and drying. The precursor was placed in a tube furnace and fired at 10° / min to 900°C under a nitrogen atmosphere and held for 1 h. The calcined sample was placed in a 5 mol / L sodium hydroxide solution and stirred at 60°C for 6 hours, and the silica template was etched to obtain a metal-based nanocatalyst Pd@NHCS-900°C supported by nitrogen-doped mesoporous hollow carbon spheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com