Method for preparing B4C nano-powder through in-situ combustion synthesis

A nano-powder, in-situ combustion technology, used in chemical instruments and methods, sustainable manufacturing/processing, carbon compounds, etc., can solve the problem of difficult control of reaction process and product morphology, low raw material utilization, and low product purity problem, to achieve the effect of controllable particle size distribution, low cost of raw materials and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

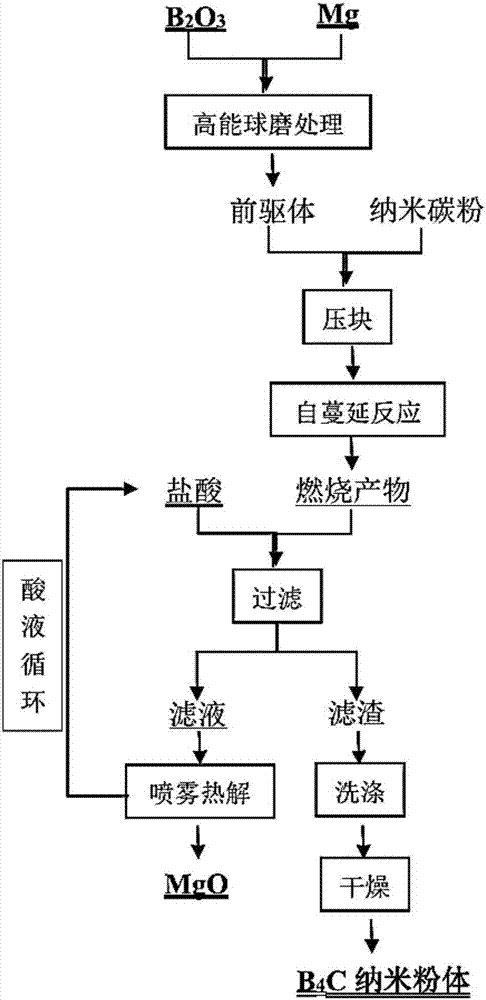

[0049] A kind of in situ combustion synthesis preparation B 4 The method of C nanometer powder, its process flow chart sees figure 1 , specifically follow the steps below:

[0050] Step 1: Mechanical Activation

[0051] Boron oxide and magnesium powder are mixed in a molar ratio, put into a high-energy ball mill for mechanical activation treatment, and a boron-containing precursor mixture is obtained; wherein, in a molar ratio, B 2 o 3 : Mg=1:3; the process parameters of the high-energy ball mill are: the mass ratio of material to ball is 1:10, the ball milling speed is 300rpm, and the ball milling time is 30min.

[0052] Step 2: Self-propagating synthesis

[0053] The boron-containing precursor mixture and carbon nanopowder are mixed evenly in molar ratio, put into a mold, pressed into a block blank at 10MPa, placed in a self-propagating reaction furnace, and the self-propagating reaction is initiated by the local ignition method, and the temperature Control at 500°C to ...

Embodiment 2

[0062] A kind of in situ combustion synthesis preparation B 4 The method of C nanometer powder, carry out as follows:

[0063] Step 1: Mechanical Activation

[0064] Boron oxide and magnesium powder are mixed in a molar ratio, put into a high-energy ball mill for mechanical activation treatment, and a boron-containing precursor mixture is obtained; wherein, in a molar ratio, B 2 o 3 : Mg=1:2.5; The process parameters of the high-energy ball mill are: the mass ratio of material to ball is 1:15, the ball milling speed is 200rpm, and the ball milling time is 60min.

[0065] Step 2: Self-propagating synthesis

[0066] Mix the boron-containing precursor mixture and carbon nanopowder evenly in molar ratio, put it into the mold, press it into a block billet at 20MPa, place it in the self-propagating reaction furnace and use the local ignition method to initiate the self-propagating reaction, the temperature Control at 800°C to obtain the reaction material, and after the reaction ...

Embodiment 3

[0075] A kind of in situ combustion synthesis preparation B 4 The method of C nanometer powder, carry out as follows:

[0076] Step 1: Mechanical Activation

[0077] Boron oxide and magnesium powder are mixed in a molar ratio, put into a high-energy ball mill for mechanical activation treatment, and a boron-containing precursor mixture is obtained; wherein, in a molar ratio, B 2 o 3 : Mg=1:3; The technological parameters of the high-energy ball mill are: the mass ratio of material to ball is 1:20, the ball milling speed is 400rpm, and the ball milling time is 100min.

[0078] Step 2: Self-propagating synthesis

[0079] The boron-containing precursor mixture and carbon nanopowder are mixed evenly in molar ratio, put into a mold, pressed into a block billet at 40MPa, placed in a self-propagating reaction furnace, and the self-propagating reaction is initiated by the local ignition method, and the temperature Control at 800°C to obtain the reaction material, and after the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com