Method for preparing catalyst carrier Al2O3 powder by activating and hydrolyzing metallic aluminium under ultrasound-electric field coupling

A catalyst carrier, electric field coupling technology, applied in catalyst carrier, catalyst activation/preparation, alumina/hydroxide preparation, etc., to achieve the effects of great economic development prospects, high activity, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

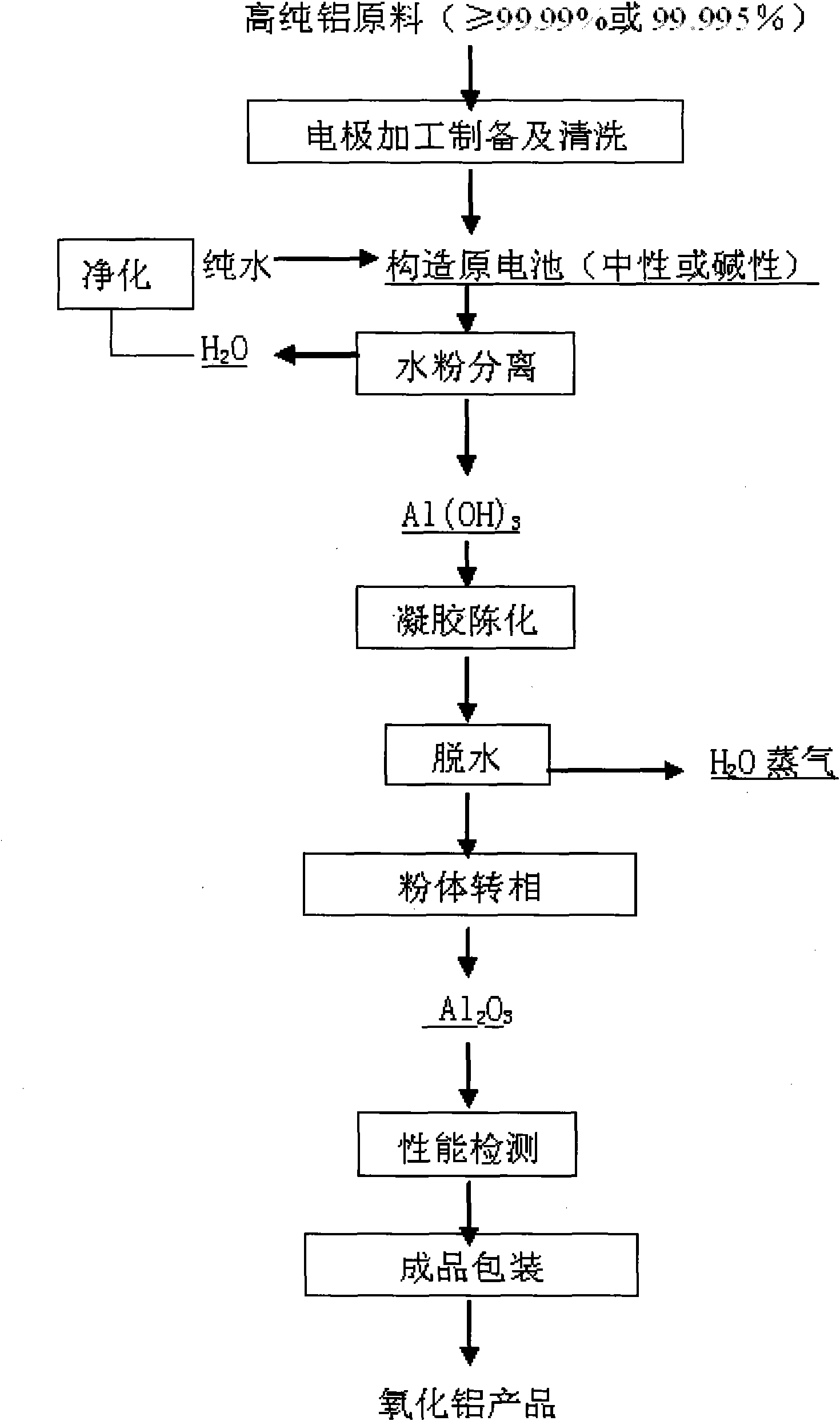

Method used

Image

Examples

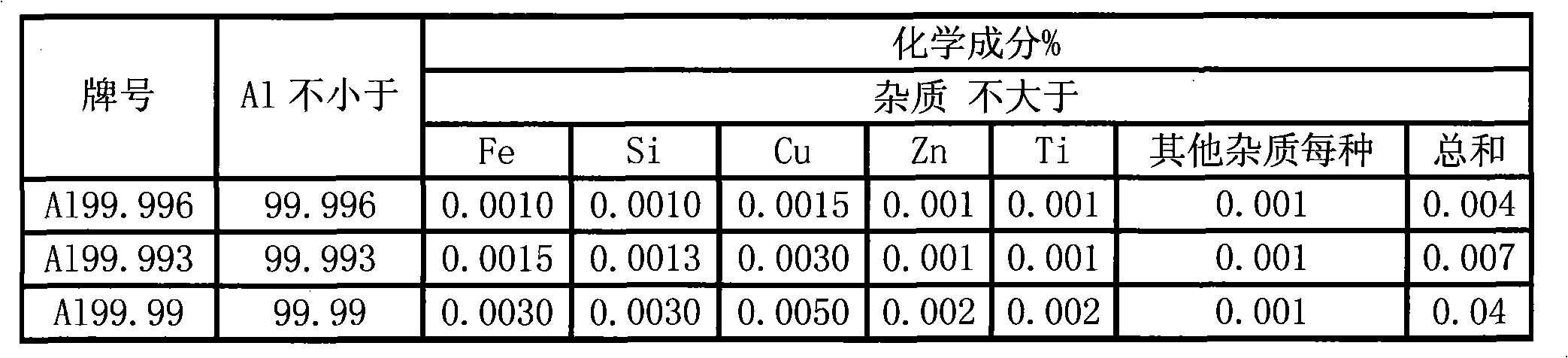

Embodiment 1

[0046] Example 1: Use a high-purity aluminum sheet with a purity of 99.999% and a size of 5×3×0.1 as raw material, electrolytically degrease, soak in 5% NaOH aqueous solution for 10 minutes, take out pure water and rinse three times, and clean The pH value is measured as neutral. Put the aluminum sheet in a 1000ml beaker to form a primary battery with the metal platinum sheet. The size of the metal platinum sheet is: 6×6×0.08, and the pure water is 750ml (resistivity: 10MΩ.cm). The water temperature is 90°C, the stirring rate is 80 rpm, and the ultrasonic generator with an ultrasonic frequency of 20KHZ and a power of 100W is started at the same time. Discharge, react for about 6 hours without bubbles, the reaction basically stops, stop stirring and ultrasonic, cut off the connection of the original battery, and cool down. Afterwards, put the reaction product into a centrifuge for dehydration, then dry it below 200°C, and perform phase inversion treatment at 1000-1100°C to obta...

Embodiment 2

[0047] Example 2: Roll 15kg of high-purity aluminum ingot with a purity of 99.99% to a sheet with a thickness of 0.5mm, cut it into an aluminum foil electrode size: 6×4×0.5, electrolytically degrease, and then pass through a 5% NaOH aqueous solution Soak for 10 minutes, take out the pure water and rinse it three times. The pH value of the cleaning is also measured as neutral. Place it directly in a 5000ml beaker with 3000ml of pure water (resistivity: 10MΩ.cm), and the platinum-plated titanium anode The grid constitutes the primary battery, the size of the platinum-coated titanium anode grid is: 6×6×0.08, (the effective area ratio of the aluminum foil electrode and the platinum-coated titanium anode grid is 1:4), the water temperature is 90°C, the stirring rate is 80 rpm, and it starts at the same time An ultrasonic generator with an ultrasonic frequency of 40KHZ and a power of 30W puts the probe in a beaker. During the stirring and ultrasonic process, the metal aluminum powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com