Continuous preparation process of high purity nanometer alumina

A nano-alumina, preparation technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of unstable product quality and low product purity, achieve the effect of improving conversion rate, overcoming low product purity, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

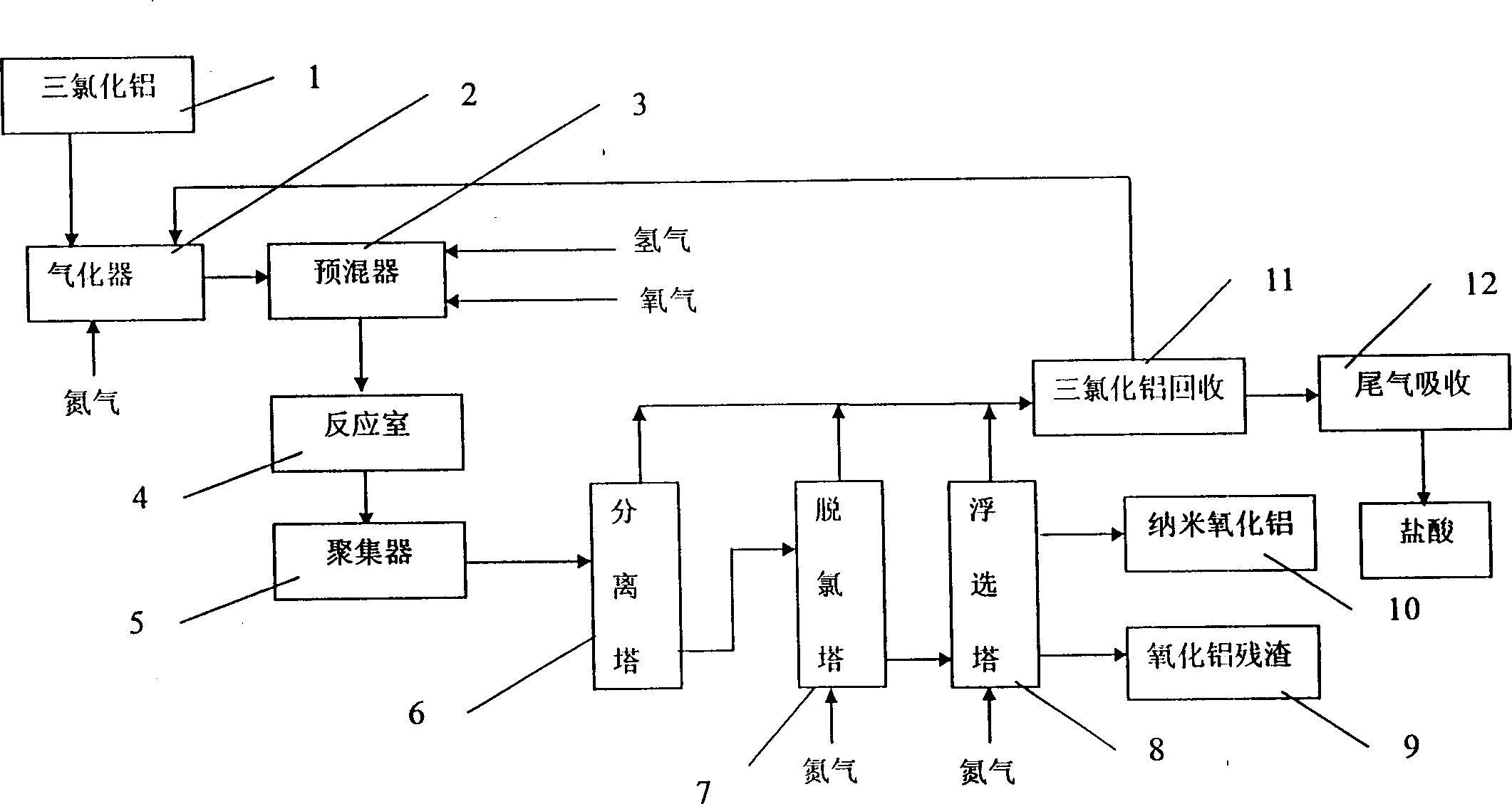

Image

Examples

Embodiment 1

[0022] Press the aluminum trichloride, hydrogen, and air to 5.5m 3 / h, 9.0m 3 / h、23.0m 3 The flow rate of / h (standard volume) is input to the premixer, and the reaction is carried out according to the above process. The temperature at the bottom of the reaction chamber (the entrance of the accumulator) is 950℃, the temperature in the first half of the accumulator is 950~600℃, and the temperature in the second half is 600~ 300°C. The temperature of the dechlorination tower is 350~500℃. The obtained nano alumina indicators are as follows:

[0023] Alumina content (%) 99.85 (atomic absorption spectrophotometer method)

[0024] Average particle size of primary particles (nm) 30 (electron microscope statistical method)

[0025] Chlorine content (%) 0.012 (potentiometric titration)

Embodiment 2

[0027] Press the aluminum trichloride, hydrogen, and air to 5.5m 3 / h、10m 3 / h、28m 3 The flow rate of / h (standard volume) is input to the premixer, and the reaction is carried out according to the above process. The temperature at the bottom of the reaction chamber (at the entrance of the accumulator) is 800℃, the temperature in the first half of the accumulator is 800~550℃, and the temperature in the second half is 550~ 300°C. The temperature of the dechlorination tower is 350~500℃. The obtained nano alumina indicators are as follows:

[0028] Alumina content (%) 99.90 (atomic absorption spectrophotometer method)

[0029] Average particle size of primary particles (nm) 12 (electron microscope statistical method)

[0030] Chlorine content (%) 0.018 (potentiometric titration).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com