Preparation method for asphalt hard carbon negative electrode material for lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unfavorable large-scale production, poor safety performance, and high equipment requirements, and achieve controllable particle size distribution and excellent lithium intercalation. , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

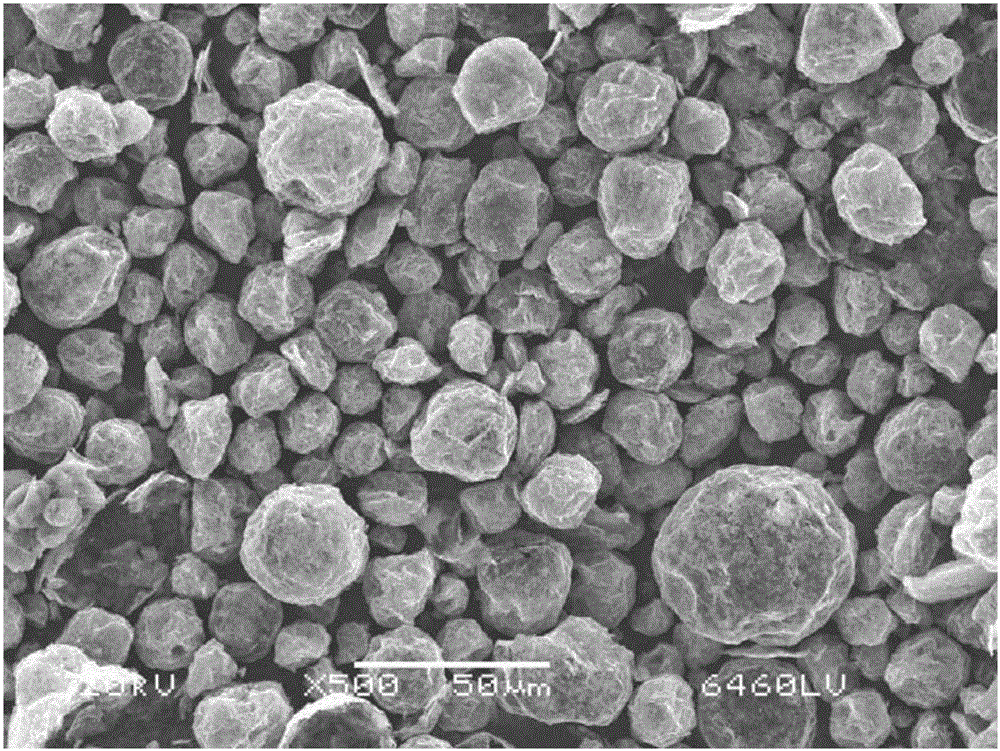

Image

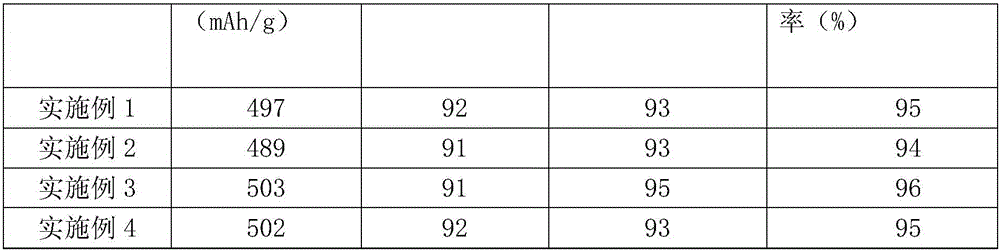

Examples

Embodiment 1

[0017] A preparation method of pitch hard carbon negative electrode material for lithium ion battery, comprising the following steps:

[0018] 1) Commercial sulfonated asphalt and deionized water were prepared as asphalt solution according to the mass ratio of 1:400, and after stirring at 500r / min for 5h, undissolved asphalt particles were filtered to obtain a clear water-soluble asphalt solution; The water solubility of the commercial sulfonated bitumen is 100%, the pH value is 7-8, and the density is greater than 0.95g / cm 3 , The softening point is greater than 150 degrees.

[0019] 2) Add the graphite micropowder to the asphalt solution obtained in step 1), stir it at a speed of 500r / min for 0.5h, and then add it into a sand mill whose speed is 2800r / min, and add 0.4 micron of oxide The zirconium beads are ground for 1 hour to obtain a graphite pitch solution; the graphite is at least one of artificial graphite or natural graphite powder; the mass ratio of the graphite pow...

Embodiment 2

[0023] A preparation method of pitch hard carbon negative electrode material for lithium ion battery, comprising the following steps:

[0024] 1) Prepare commercial sulfonated asphalt and deionized water at a mass ratio of 1:50 to make an asphalt solution, stir at 2000r / min for 0.5h, filter out undissolved asphalt particles, and obtain a clear water-soluble asphalt solution; The water solubility of the commercial sulfonated pitch is 50%, the pH value is 7-8, and the density is greater than 0.95g / cm 3 , The softening point is greater than 150 degrees.

[0025] 2) Add graphite micropowder to the asphalt solution obtained in step 1), stir at 2000r / min for 0.5h, and then add it into a sand mill with a speed of 2800r / min, and add 0.3um oxide The zirconium beads were ground for 8 hours to obtain a graphite pitch solution; the graphite was artificial graphite; the mass ratio of the graphite micropowder to the pitch in the pitch solution was 1:100.

[0026] 3) The graphite pitch sol...

Embodiment 3

[0029] A preparation method of pitch hard carbon negative electrode material for lithium ion battery, comprising the following steps:

[0030] 1) Prepare commercial sulfonated asphalt and deionized water at a mass ratio of 1:100 to make an asphalt solution, stir at 1000r / min for 3.5 hours, filter out undissolved asphalt particles, and obtain a clear water-soluble asphalt solution; The water solubility of the commercial sulfonated asphalt is 60%, the pH value is 7-8, and the density is greater than 0.95g / cm 3 , The softening point is greater than 150 degrees.

[0031] 2) Add the graphite micropowder to the asphalt solution obtained in step 1), stir for 4.5 hours at a speed of 1000r / min, and then add it to a sand mill whose speed is 2500r / min, and add 0.3um oxide The zirconium beads were ground for 6 hours to obtain a graphite pitch solution; the graphite was a fine powder of natural graphite; the mass ratio of the graphite fine powder to the pitch in the pitch solution was 1:5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com