Preparation method of amorphous SiOC ceramic powder

A ceramic powder and amorphous technology, which is applied in the field of preparation of amorphous SiOC ceramic powder, can solve the problems of high-purity amorphous SiOC ceramic powder, low purity of amorphous SiOC ceramic powder, and difficulty in industrial application. Achieve the effect of controllable powder particle size distribution, solve the problem of high cost of raw materials, and easy control of structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of amorphous SiOC ceramic powder, comprising the following steps:

[0032] 1) Using 10.08wt% oxygen, the main chain is Si-CH 2 -Si, and Si and CH in the main chain at the same time 3 The linear polycarbosilane (LPCS) with the group connected to the H group is used as a precursor polymer, and the precursor is 2 Under the atmosphere, from room temperature, the temperature was raised to 190°C at a rate of 10°C / min, kept for 1 hour for cross-linking and curing, and then the cross-linked and cured product was crushed and passed through a 60-mesh sieve to obtain precursor particles;

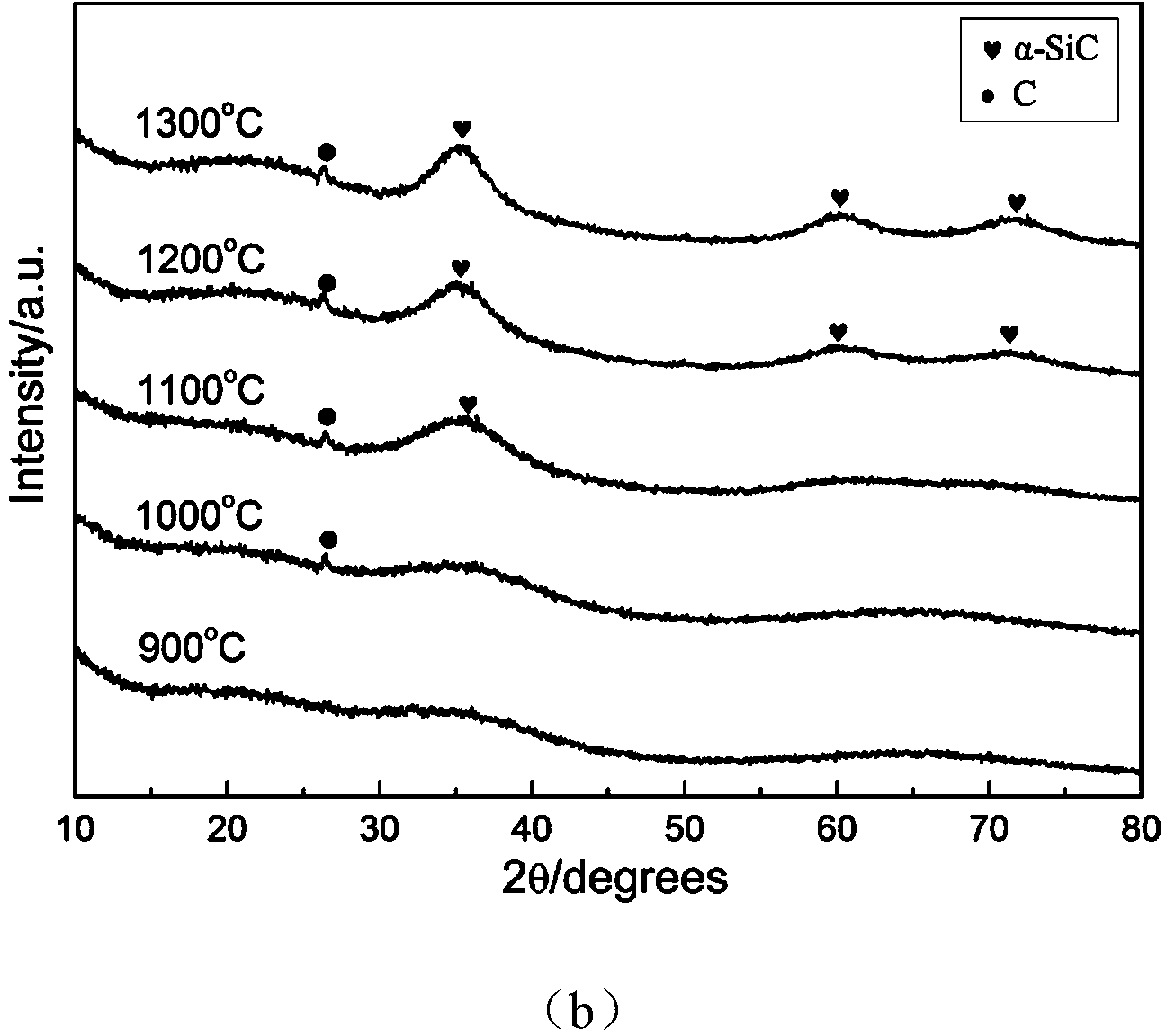

[0033] 2) Put the precursor particles in the tube furnace, under N 2 Under the atmosphere, from room temperature to 900 °C at a rate of 2 °C / min, keep the temperature for 1 hour, and cool to room temperature with the furnace after the heat preservation is over, to obtain pyrolytic ceramic particles with a particle size of 60 μm-2 mm and irregular particle shape ;

[0034...

Embodiment 2

[0038] A preparation method of amorphous SiOC ceramic powder, comprising the following steps:

[0039] 1) Using 10.08wt% oxygen, the main chain is Si-CH 2 -Si, and Si and CH in the main chain at the same time 3 The linear polycarbosilane (LPCS) whose group is connected to the H group and the main chain is Si-O-Si, and Si in the main chain is simultaneously with CH 3 The group is connected to the H group, and the linear polysiloxane (LPSO) with an average relative molecular weight of 1700-3200 is used as a precursor polymer, and the mass ratio of polycarbosilane and polysiloxane is: 75:25 Mixing, magnetic stirring for 20min, the precursor in N 2 Under the atmosphere, from room temperature, the temperature was raised to 190°C at a rate of 10°C / min, kept for 1 hour for cross-linking and curing, and then the cross-linked and cured product was crushed and passed through a 60-mesh sieve to obtain precursor particles;

[0040] 2) Put the precursor particles in the tube furnace, un...

Embodiment 3

[0045] A preparation method of amorphous SiOC ceramic powder, comprising the following steps:

[0046] 1) Using 10.08wt% oxygen, the main chain is Si-CH 2 -Si, and Si and CH in the main chain at the same time 3 The linear polycarbosilane (LPCS) whose group is connected to the H group and the main chain is Si-O-Si, and Si in the main chain is simultaneously with CH 3 The group is connected to the H group, and the linear polysiloxane (LPSO) with an average relative molecular weight of 1700-3200 is used as a precursor polymer, and polycarbosilane and polysiloxane are mixed in a mass ratio of 60:40 , magnetic stirring for 20min, the precursor in N 2 Under the atmosphere, from room temperature, the temperature was raised to 190°C at a rate of 10°C / min, and kept for 1 hour for cross-linking and curing, and then the cross-linked and cured product was crushed and passed through a 40-mesh sieve to obtain precursor particles;

[0047] 2) Put the precursor particles in the tube furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

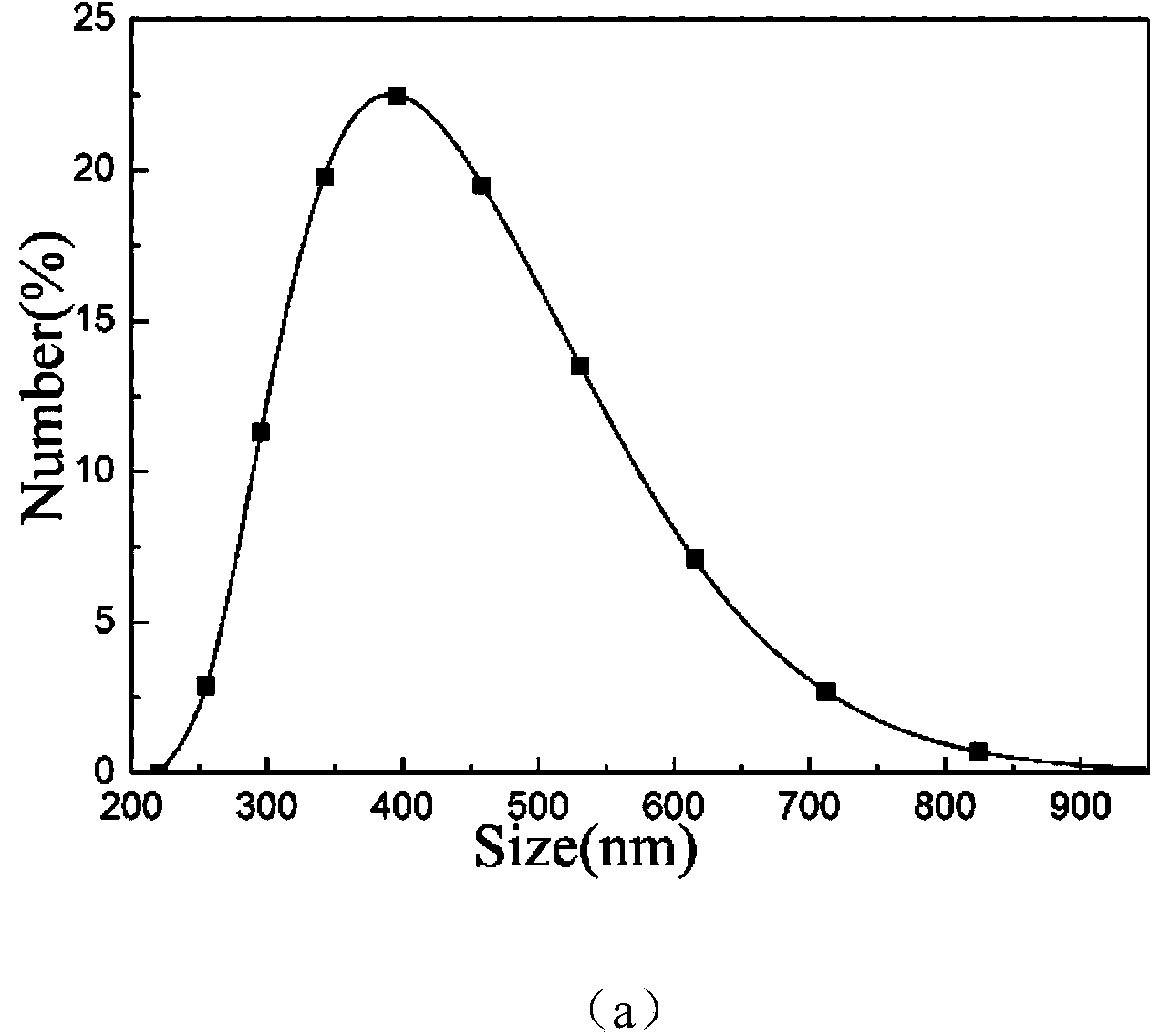

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com