Method for producing nano-titanium dioxide by gelation method

A technology of nano-titanium dioxide and gelation, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of particle size, difficult distribution, harsh conditions of gas phase method, high cost of raw materials, etc., to achieve easy surface treatment, The effect of simple equipment and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

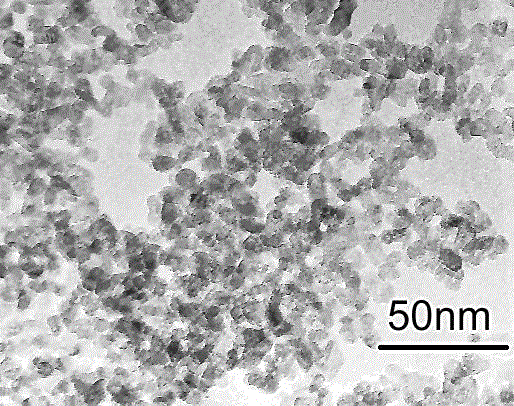

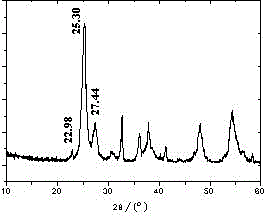

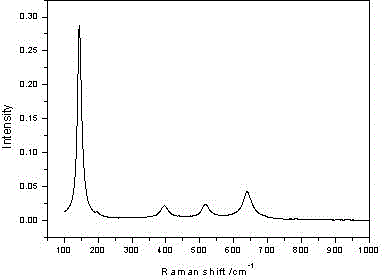

Embodiment 1

[0053] 20Kg of TiCl 4 Put it into a 50L reactor, continuously feed air at a rate of 60L / h, slowly inject 3600g of distilled water with a large needle under stirring, and stir for 10 minutes. The gas discharged from the reactor is introduced into the absorption system for treatment. The material taken out from the reactor was transferred to a container with a suction device for further hydrolysis into puffy products, and then calcined at 300°C for 15 minutes. During calcination, air was introduced at a rate of 40L / h to maintain the oxidizing atmosphere of the system. For the grading treatment of the burned out, tens to tens of nanometers can be obtained, mainly sharp nano-TiO 2 particle.

Embodiment 2

[0055] 15Kg of TiCl 4 Put it into a 50L reaction kettle, and continuously feed air. Dissolve 60g of ZnCl in 2.8 liters of deionized water 2 , Slowly inject the solution into the reaction kettle with a large needle under stirring, and stir for 15 minutes. The gas discharged from the reactor is sent to the absorption system for treatment. Transfer the material to a container with an air extraction device to further absorb an appropriate amount of water vapor to make it bulky. Then calcined at 500°C for 20min. Air should also be introduced during calcination to maintain the oxidizing atmosphere of the system. For the grading treatment of the burned out, tens of nanometers of TiO mainly rutile can be obtained 2 particle.

Embodiment 3

[0057] 35Kg of TiCl 4 Put it into a 50L reactor, and continuously feed air at a rate of 60L / h. Dissolve 74g KNO with 4700g distilled water 3 and 42g of phosphoric acid, mix well, and slowly inject the solution into the reactor with a needle under stirring. Agitate for 15 minutes. The gas discharged from the reactor is sent to the absorption system for treatment. Transfer the material taken out from the reaction kettle to a container with a suction device, and further absorb an appropriate amount of water to make it bulky. Then calcined at 400°C for 30min. During calcination, air is introduced at a rate of 40L / h to maintain the oxidizing atmosphere of the system, and the gas and air released from the reaction should be introduced into the absorption system for treatment. For the classification treatment of the burned out, tens to tens of nanometers of sharp TiO2 particles can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com