A straw crushing device

A straw pulverizing and straw technology is applied in the field of straw pulverizing devices, which can solve the problems of poor material adaptability, high labor intensity, monotonous process, etc., and achieve the effects of long service life of the machine, high pulverization efficiency, and continuous feeding and discharging of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

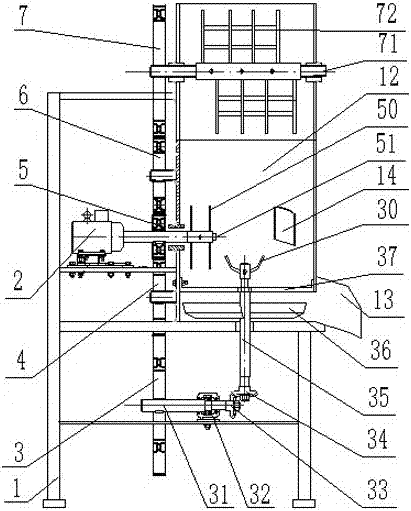

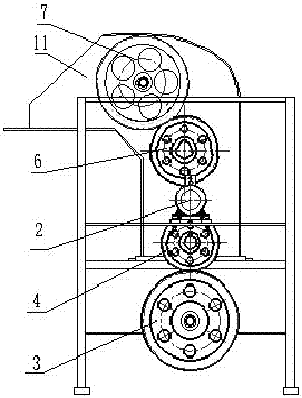

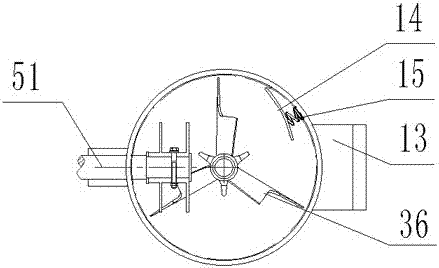

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0023] A straw crushing device, comprising: a frame 1, a drive motor 2 placed on the frame 1, a feed port 11 for receiving straw, a discharge port 13 for releasing chopped straw, and a crushing device for crushing and stirring the straw. The barrel 12 is connected between the feeding port 11 and the crushing barrel 12 and is connected to the feeding transmission assembly of the drive motor 2, placed in the crushing barrel 12 and connected to the stirring assembly of the drive motor 2, placed in the crushing barrel 12 and The crushing assembly connected to the drive motor 2 is placed in the crushing barrel 12 and used to limit the straw material within the contact range of the crushing assembly. The guide assembly is connected between the crushing barrel 12 and the discharge port 13 and connected to the drive motor 2 pusher components. As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com