A kind of multistage porous sapo-11 molecular sieve and its synthesis method and application

A SAPO-11, molecular sieve technology, applied in the direction of molecular sieve and alkali exchange phosphate, containing molecular sieve catalyst, molecular sieve characteristic silicoaluminophosphate, etc. The effect of low cost and reduced waste liquid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

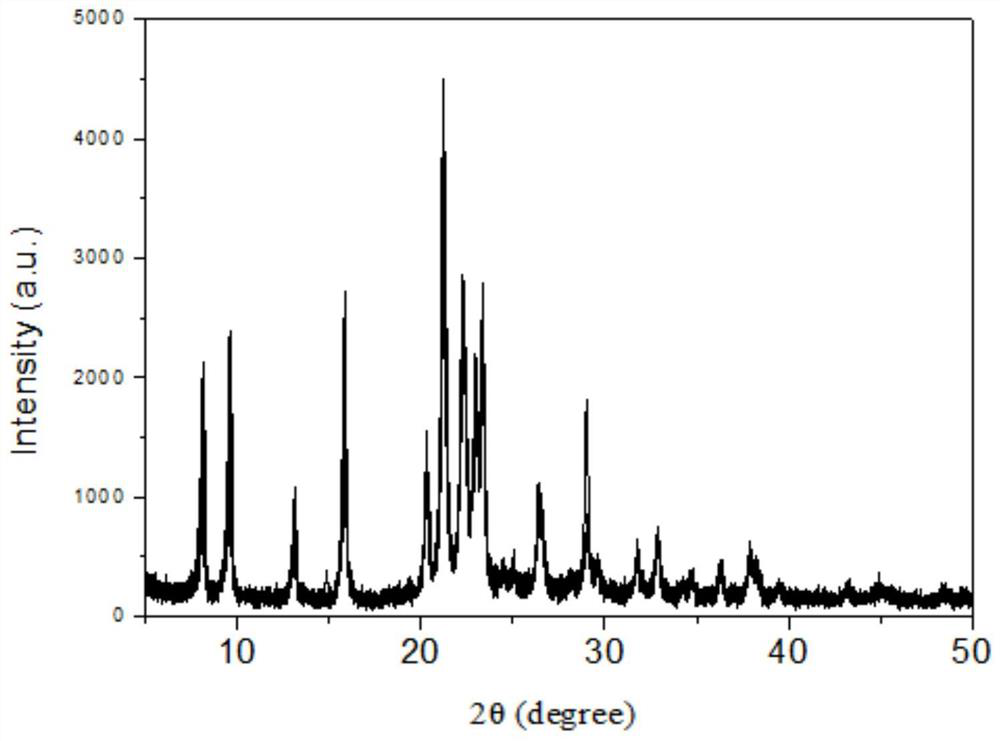

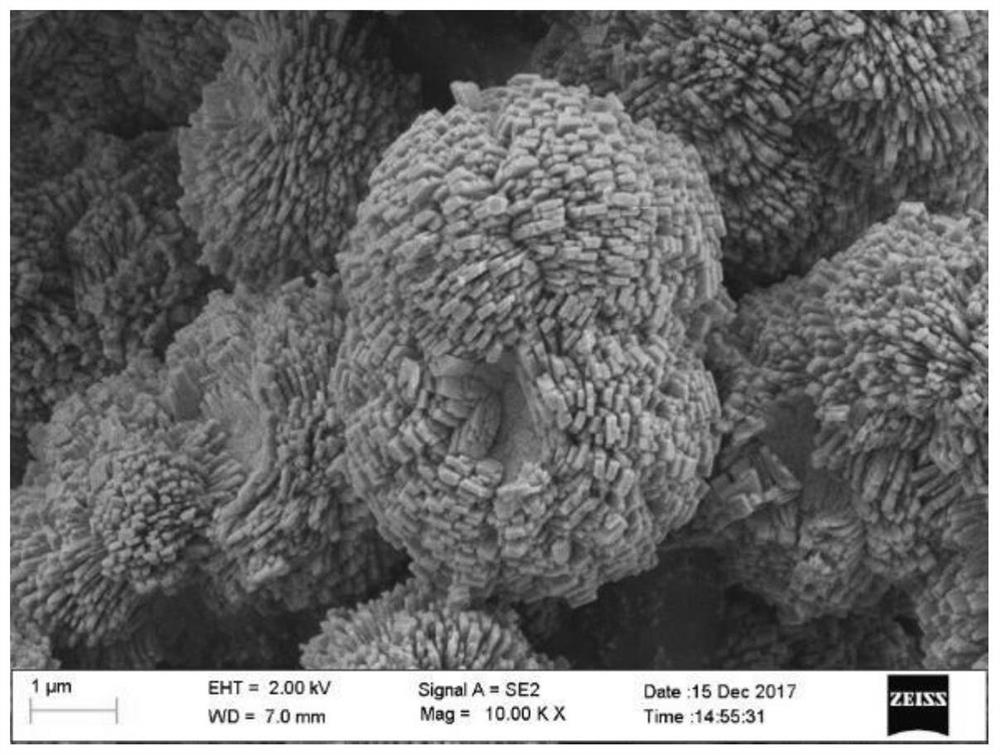

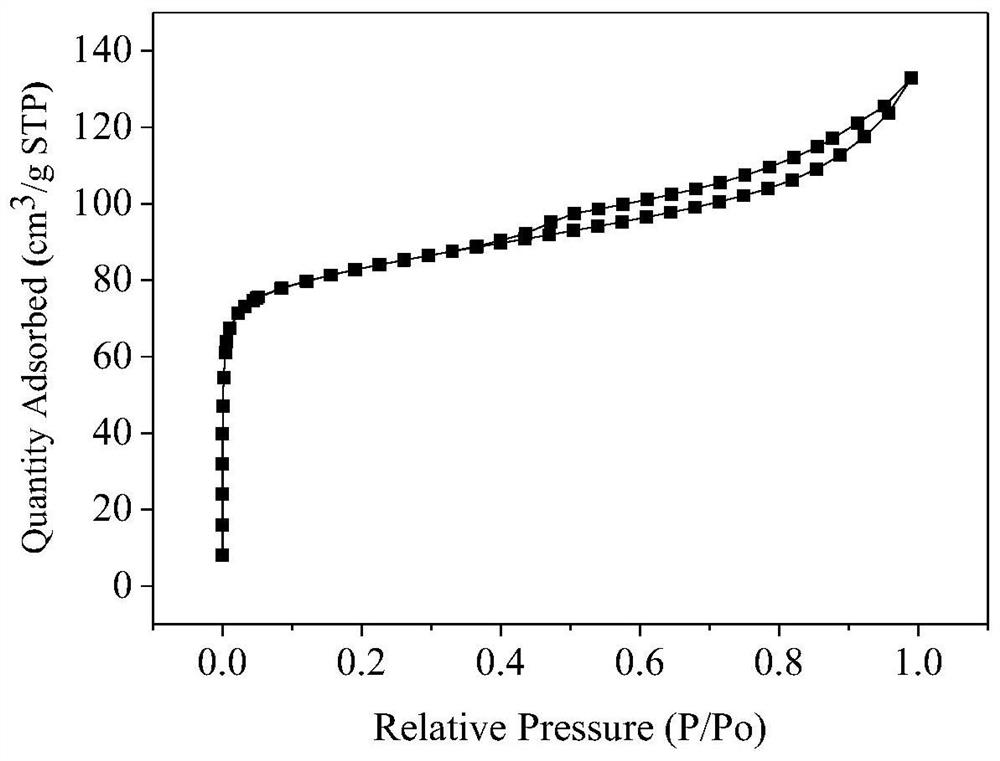

[0042] Weigh 10g laboratory synthetic SAPO-11 molecular sieve former powder (such as figure 1 is the XRD spectrum of the original powder, figure 2 It is the scanning electron microscope photograph of former powder) and 0.1g solid-phase oxalic acid, add in pulverizer and pulverize, make solid-state reactant mix uniformly. Then the raw materials were transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, put into an oven, and reacted at 100°C for 6h to obtain a multi-stage porous SAPO-11 molecular sieve.

[0043] Figure 4 It is the XRD spectrum of the product, it can be seen that the product is a typical AEL structure with good relative crystallinity

[0044] Figure 5 It is the SEM scanning electron microscope photo of the product. It can be seen that the product consists of spherical particles with a particle size of 6-10 μm accumulated by flake crystals. Compared with the original powder, there are a small amount of shedding crystals on the surfa...

Embodiment 2

[0046]Weigh 10 g of laboratory-synthesized SAPO-11 molecular sieve raw powder and 0.1 g of solid-phase oxalic acid, put them into a pulverizer and pulverize them, so that the solid-state reactants are evenly mixed. Then the raw material was transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, and placed in an oven, and reacted at 100°C for 12h to obtain a multi-stage porous SAPO-11 molecular sieve.

[0047] Figure 6 It is the XRD spectrum of the product, it can be seen that the product is a typical AEL structure with good crystallinity.

[0048] Figure 7 It is the SEM scanning electron microscope photo of the product, it can be seen that the product is composed of flaky crystals with a particle diameter of 6-10 μm spherical particles, and the surface is compared with that of Example 1. figure 2 More crystals are shed.

Embodiment 3

[0050] Weigh 10 g of laboratory-synthesized SAPO-11 molecular sieve raw powder and 0.15 g of solid oxalic acid, put them into a pulverizer and pulverize them, so that the solid reactants are evenly mixed. Then the raw materials were transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, put into an oven, and reacted at 100°C for 6h to obtain a multi-stage porous SAPO-11 molecular sieve.

[0051] Figure 8 It is the XRD spectrum of the product, it can be seen that the product is a typical AEL structure with good crystallinity.

[0052] Figure 9 It is the SEM scanning electron microscope photo of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com