Novel thermal-insulating energy-saving material

A thermal insulation and energy-saving material and a new type of technology, applied in the field of energy-saving materials, can solve the problems of high water absorption rate of inorganic materials, affect thermal insulation effect, easy aging, etc., and achieve excellent thermal insulation and energy saving performance, good machining performance, heat resistance and high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

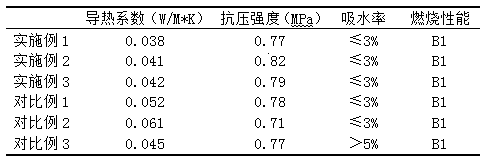

Examples

Embodiment 1

[0028] (1) 25 parts of fly ash, 25 parts of slag, 3.3 parts of small particle expanded perlite with a particle size of 2-5mm, 6.7 parts of expanded pearl powder with a particle size of 0.5-2mm, 8 parts of glass wool, sepiolite 5 parts, 5 parts of aluminum silicate cotton, and 5 parts of water-repellent agent were mixed in proportion, crushed by a crusher, sieved to 20 mesh, added deionized water and mixed evenly to obtain slurry a;

[0029] (2) Add 10 parts of aluminum dihydrogen phosphate and 3 parts of nano-silica airgel to the slurry a, put it into a stirrer, stir at a speed of 2500 rpm for 30 minutes, and obtain slurry b;

[0030] (3) Foaming 10 parts of polystyrene, 5 parts of cellulose ether and 10 parts of polyurethane composite material at 60°C to obtain a foaming liquid;

[0031] (4) Mix the foaming liquid and slurry b, and stir for 2 hours to obtain slurry c;

[0032] (5) After the mold is covered with a release agent, the slurry c is added for injection molding, an...

Embodiment 2

[0035] (1) 20 parts of fly ash, 20 parts of slag, 3 parts of small particle expanded perlite with a particle size of 2-5mm, 6 parts of expanded pearl powder with a particle size of 0.5-2mm, 8 parts of glass wool, sepiolite 3 parts, 3 parts of aluminum silicate wool, 2 parts of water-repellent agent were mixed in proportion, crushed by a crusher, sieved to 10 mesh, added deionized water and mixed evenly to obtain slurry a;

[0036] (2) Add 5 parts of aluminum dihydrogen phosphate and 3 parts of nano-silica airgel to the slurry a, put it into a stirrer, stir at a speed of 2000 rpm for 30 minutes, and obtain the slurry b;

[0037] (3) Foaming 10 parts of polystyrene, 3 parts of cellulose ether and 6 parts of polyurethane composite material at 60°C to obtain a foaming liquid;

[0038] (4) Mix the foaming liquid and slurry b, and stir for 2 hours to obtain slurry c;

[0039] (5) After the mold is covered with a release agent, the slurry c is added for injection molding, and baked ...

Embodiment 3

[0042] (1) 30 parts of fly ash, 30 parts of slag, 2 parts of small particle expanded perlite with a particle size of 2-5mm, 4 parts of expanded pearl powder with a particle size of 0.5-2mm, 15 parts of glass wool, sepiolite 8 parts, 8 parts of aluminum silicate cotton, and 5 parts of water-repellent agent were mixed in proportion, crushed by a crusher, sieved to 5 mesh, added deionized water and mixed evenly to obtain slurry a;

[0043] (2) Add 10 parts of aluminum dihydrogen phosphate and 5 parts of nano-silica airgel to slurry a, put it into a stirrer, and stir at a speed of 3000 rpm for 30 minutes to obtain slurry b;

[0044] (3) Foaming 15 parts of polystyrene, 5 parts of cellulose ether and 12 parts of polyurethane composite material at 60°C to obtain a foaming liquid;

[0045](4) Mix the foaming liquid and slurry b, and stir for 3 hours to obtain slurry c;

[0046] (5) Fill the mold with release agent, add slurry c for injection molding, and bake in an oven at 90°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com