Multi-stage porous SAPO-11 molecular sieve and synthesis method and application thereof

A technique for the synthesis of SAPO-11, which is applied in the direction of molecular sieves and alkali-exchanged phosphates, including molecular sieve catalysts, molecular sieve characteristic silicoaluminophosphates, etc., can solve the problems such as the single channel structure of SAPO-11 molecular sieves, and achieve high crystallinity, The effect of reducing waste liquid discharge and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

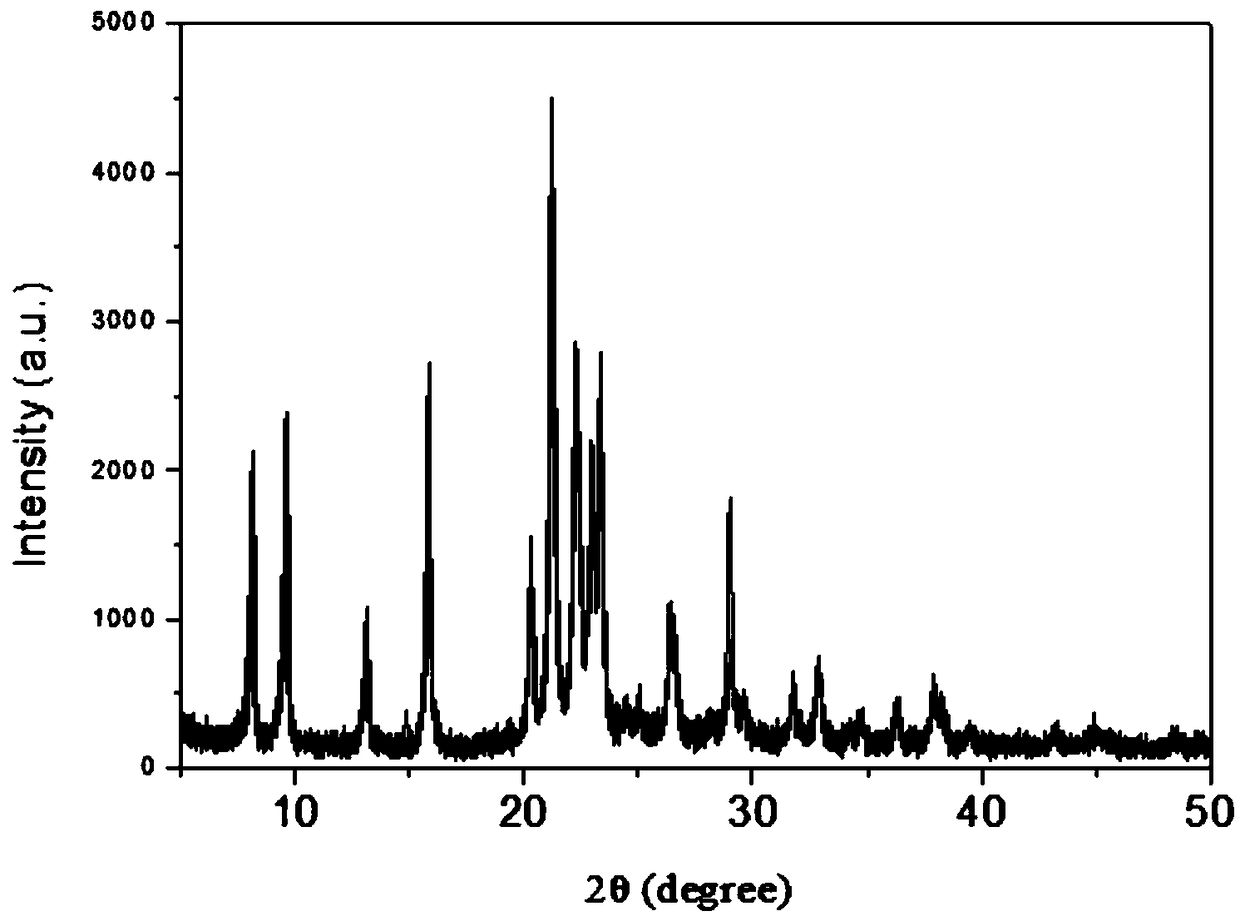

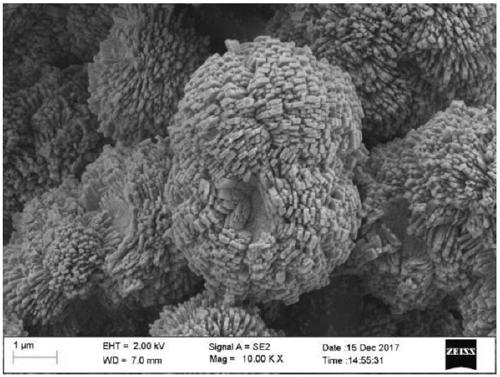

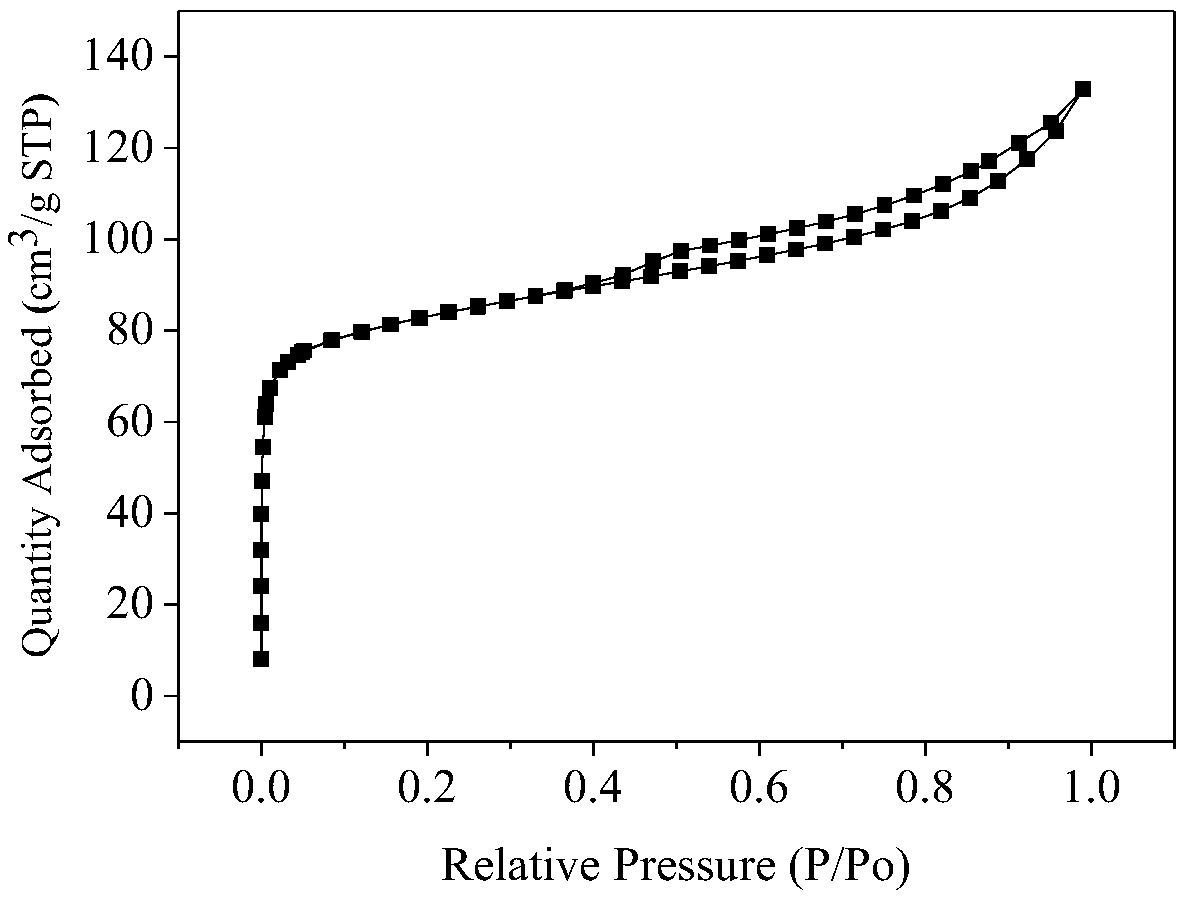

[0042] Weigh 10g laboratory synthetic SAPO-11 molecular sieve former powder (such as figure 1 is the XRD spectrum of the original powder, figure 2 It is the scanning electron microscope photograph of former powder) and 0.1g solid-phase oxalic acid, add in pulverizer and pulverize, make solid-state reactant mix uniformly. Then the raw material was transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, and placed in an oven, and reacted at 100°C for 6h to obtain a multi-stage porous SAPO-11 molecular sieve.

[0043] Figure 4 It is the XRD spectrum of the product, it can be seen that the product is a typical AEL structure with good relative crystallinity

[0044] Figure 5 It is the SEM scanning electron microscope photo of the product. It can be seen that the product consists of spherical particles with a particle size of 6-10 μm accumulated by flake crystals. Compared with the original powder, there are a small amount of shedding crystals on the su...

Embodiment 2

[0046]Weigh 10 g of laboratory-synthesized SAPO-11 molecular sieve raw powder and 0.1 g of solid-phase oxalic acid, put them into a pulverizer and pulverize them, so that the solid-state reactants are evenly mixed. Then the raw material was transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, and placed in an oven, and reacted at 100°C for 12h to obtain a multi-stage porous SAPO-11 molecular sieve.

[0047] Figure 6 It is the XRD spectrum of the product, it can be seen that the product is a typical AEL structure with good crystallinity.

[0048] Figure 7 It is the SEM scanning electron microscope photo of the product, it can be seen that the product is composed of flaky crystals with a particle diameter of 6-10 μm spherical particles, and the surface is compared with that of Example 1. figure 2 More crystals are shed.

Embodiment 3

[0050] Weigh 10 g of laboratory-synthesized SAPO-11 molecular sieve raw powder and 0.15 g of solid oxalic acid, put them into a pulverizer and pulverize them, so that the solid reactants are evenly mixed. Then the raw material was transferred to a 100ml polytetrafluoroethylene-lined stainless steel autoclave, and placed in an oven, and reacted at 100°C for 6h to obtain a multi-stage porous SAPO-11 molecular sieve.

[0051] Figure 8 It is the XRD spectrum of the product, it can be seen that the product is a typical AEL structure with good crystallinity.

[0052] Figure 9 It is the SEM scanning electron microscope photo of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com