High-solid anaerobic reaction device and method for organic garbage

An anaerobic reaction device and organic waste technology, which is applied in the field of waste resource utilization, can solve the problem of not considering the material crushing and pretreatment process, the unevenness of the material, the complicated device, the inability to ensure the long-term stable operation of the dry fermentation process, and the inability to guarantee the material First-in first-out and other issues, to achieve the effect of benefiting the anaerobic fermentation process, small footprint, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

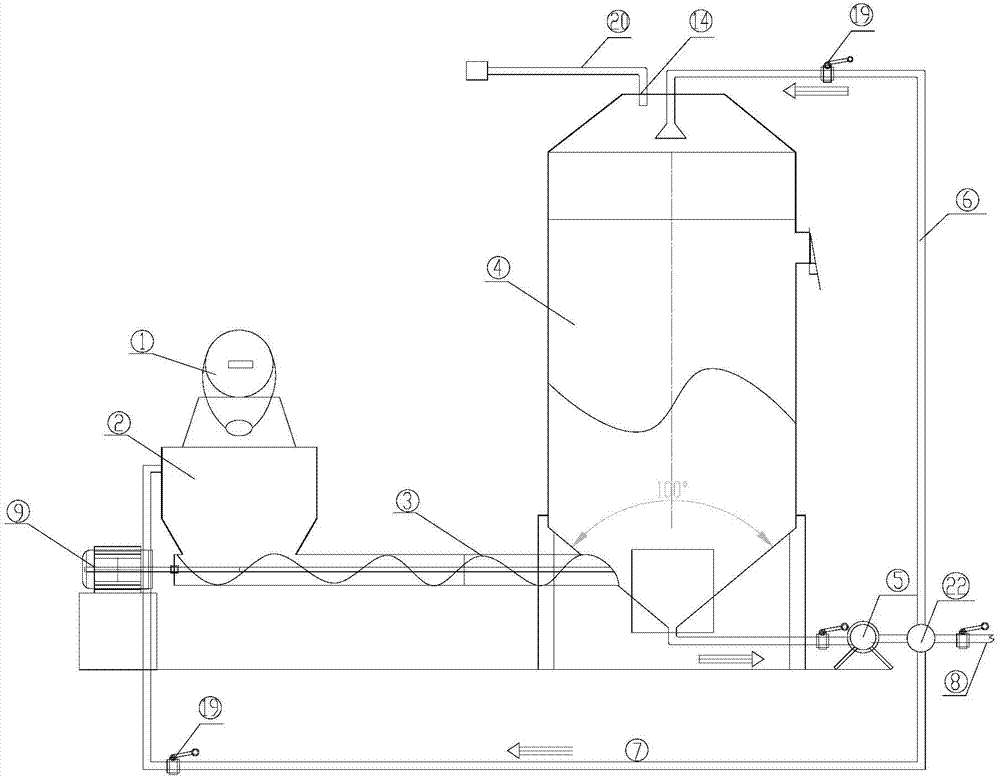

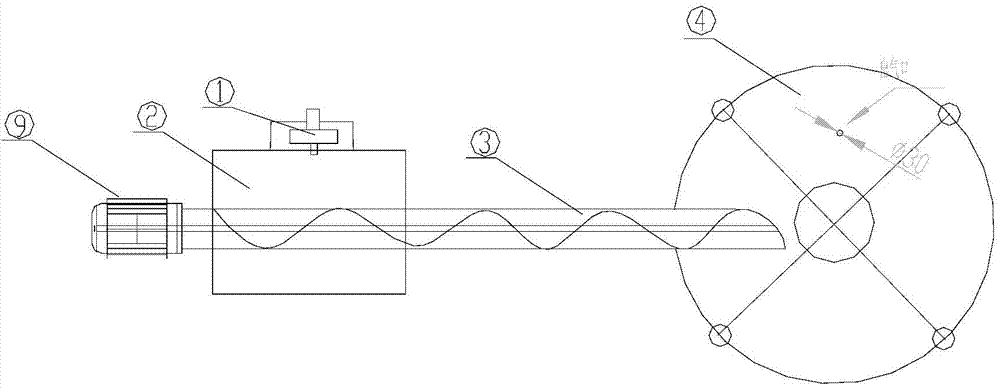

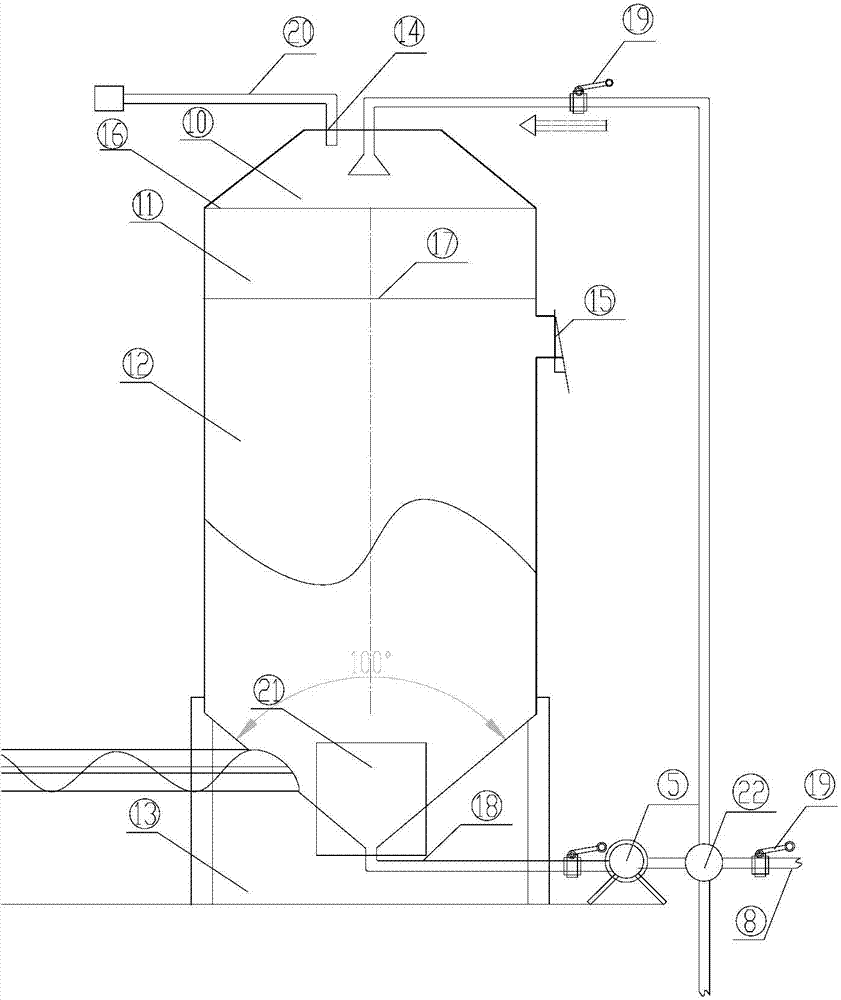

[0041] A high-solid anaerobic reaction device for organic waste, the structure of which is as follows Figure 1-Figure 5 As shown, it includes a pulverizer 1, a pretreatment tank 2 and an anaerobic fermentation tank 4. The pulverizer 1 is arranged above the pretreatment tank 2. The top of the pretreatment tank 2 is provided with a movable cover plate, and the bottom is provided with a discharge port. The discharge port of the pulverizer 1 passes through the cover plate of the pretreatment tank 2 and communicates with the inside of the pretreatment tank 2, and a screw conveyor 3 is arranged below the discharge port of the pretreatment tank 2, and the periphery of the discharge port of the pretreatment tank 2 is connected to the The feed port of the screw conveyor 3 is sealed and connected, and a stirring device is also arranged in the pretreatment tank 2, and the discharge port of the screw conveyor 3 is connected with the feed port of the anaerobic fermentation tank 4;

[0042...

Embodiment 2

[0047] A kind of organic waste high solid anaerobic reaction device, structure as shown in embodiment 1, difference is,

[0048] Pebbles are filled in the cavity of the percolation layer 13, and the average particle size of the pebbles is 3 cm.

[0049] One end of the biogas slurry spray return pipe 6 located in the anaerobic fermentation tank 4 is expanded into a trumpet shape, the distance between the trumpet-shaped nozzle and the perforated plate is 50 cm, and the height of the spraying area is 35 cm. The height of the fermentation zone is 4.5m. The thickness of the insulation layer is 10cm, the aperture of the small hole on the spray perforated plate is 0.3cm, and the center distance between the hole and the hole is 3cm, and the effective volume of the pretreatment tank is 1 / 15 of the effective volume of the anaerobic fermentation zone. The bottom of the fermenter is in the shape of an inverted cone with a taper angle of 120°.

Embodiment 3

[0051] A kind of organic waste high solid anaerobic reaction device, structure as shown in embodiment 1, difference is,

[0052] Pebbles are filled in the cavity of the percolation layer 13, and the average particle size of the pebbles is 2.5 cm.

[0053] One end of the biogas slurry spray return pipe 6 located in the anaerobic fermentation tank 4 expands into a trumpet shape, and the distance between the trumpet-shaped nozzle and the perforated plate is 35 cm, and the height of the spraying area is 30 cm. The height of the fermentation zone is 3m. The thickness of the insulation layer is 9cm, the aperture of the small hole on the spray perforated plate is 0.5cm, the center distance between the hole and the hole is 4cm, and the effective volume of the pretreatment tank is 1 / 12 of the effective volume of the anaerobic fermentation zone. The bottom of the fermenter is in the shape of an inverted cone, and the cone angle of the inverted cone is 110°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com