Continuous coating device for coating layer on surface of cable and method thereof

A coating device and surface coating technology, applied in coating, metal material coating process, sputtering coating, etc., can solve the problems such as the volume is not easy to be too large, the continuous surface processing of silicone rubber cables is not possible, and the application scope of Parylene is limited. , to achieve the effect of reducing the pressure difference and improving the coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] After extensive and in-depth research, the inventor has developed a set of continuous coating system that can coat the surface of silicone rubber cables of any length through reasonable vacuum structure design, which can realize the winding and unwinding of both ends of the cable in the atmospheric environment At the same time, the surface of the cable is quickly and continuously coated with Parylene in the vacuum chamber.

[0037] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0038] Silicone cable surface coating continuous coating device

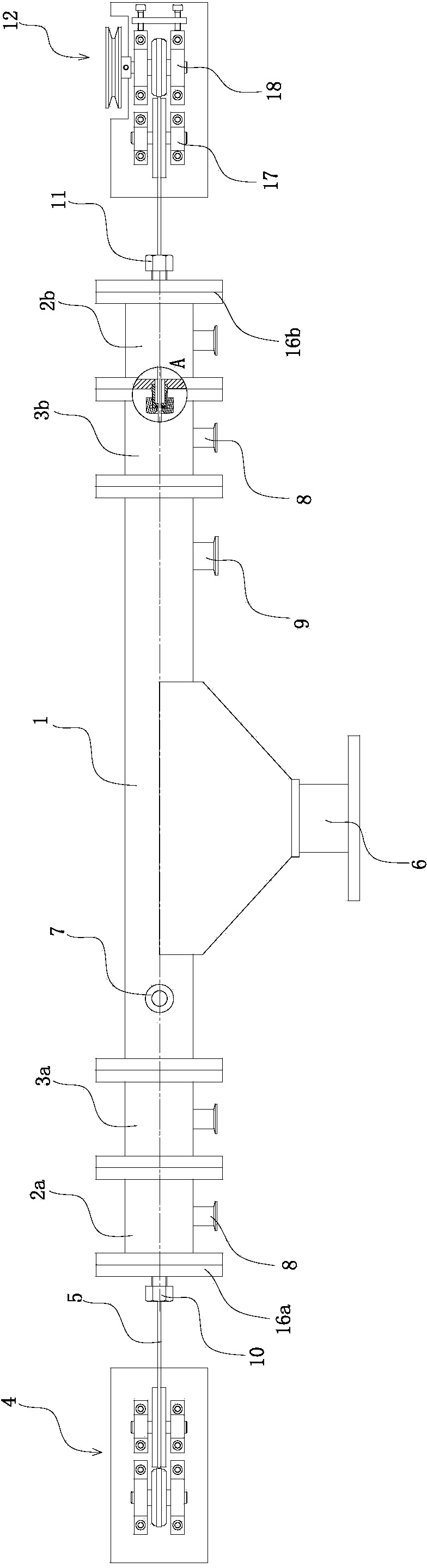

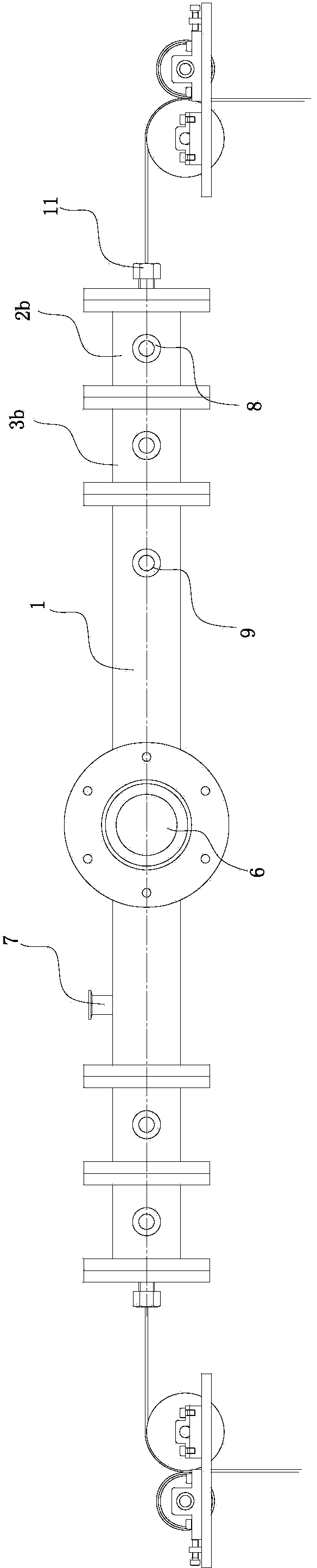

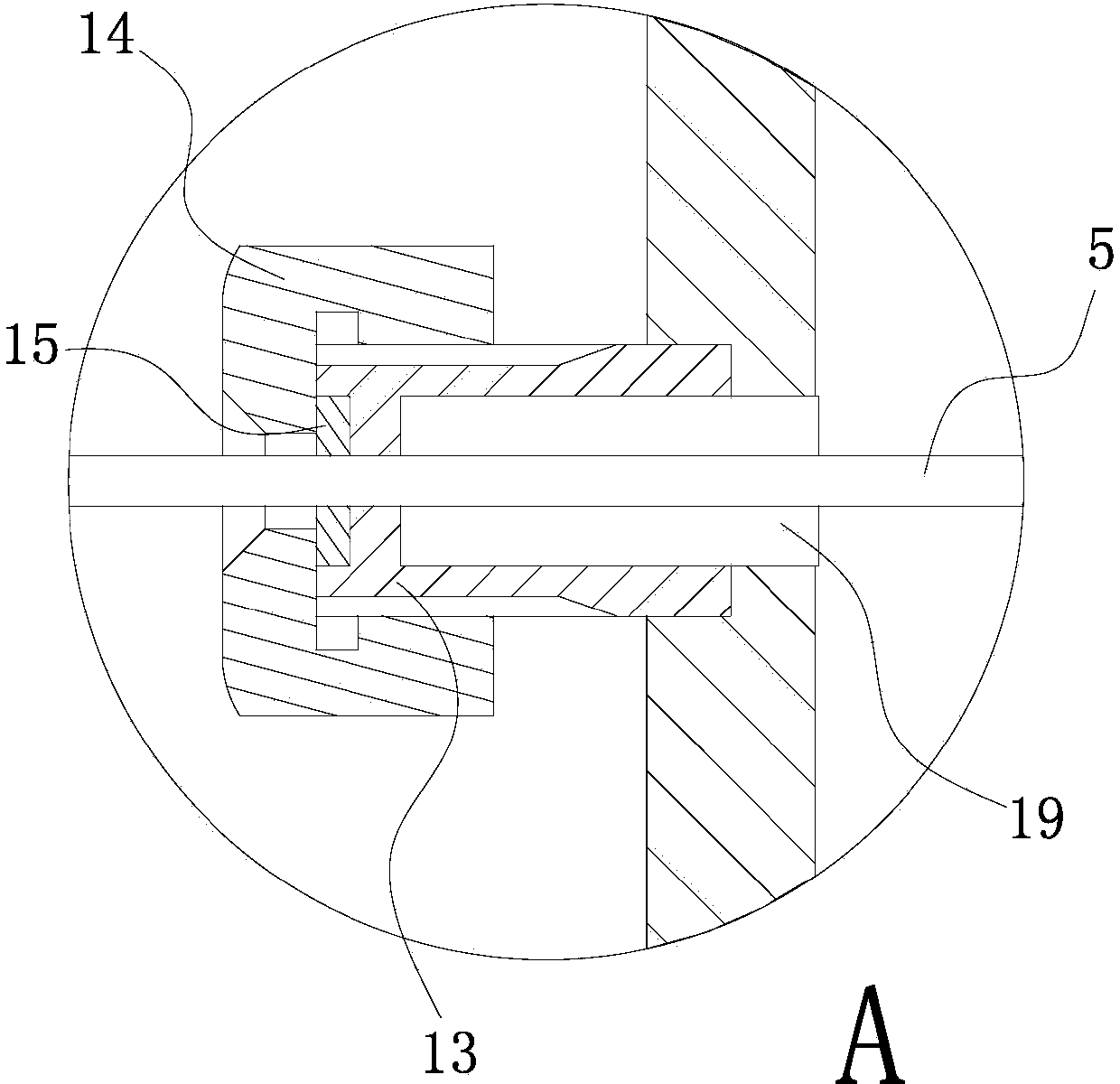

[0039] Figure 1a and 1b They are respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com