Air energy high-temperature heat pump tunnel type multifunctional drying production equipment

A technology for high-temperature heat pumps and production equipment, applied to lighting and heating equipment, drying, drying machines, etc., can solve the problems of large volume, uneven drying, and low drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

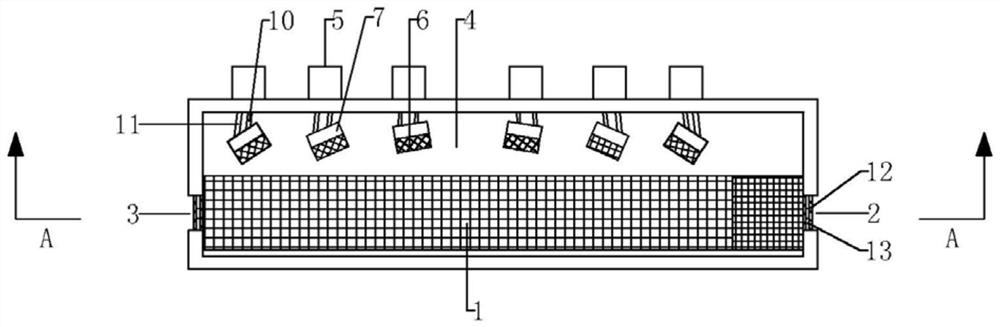

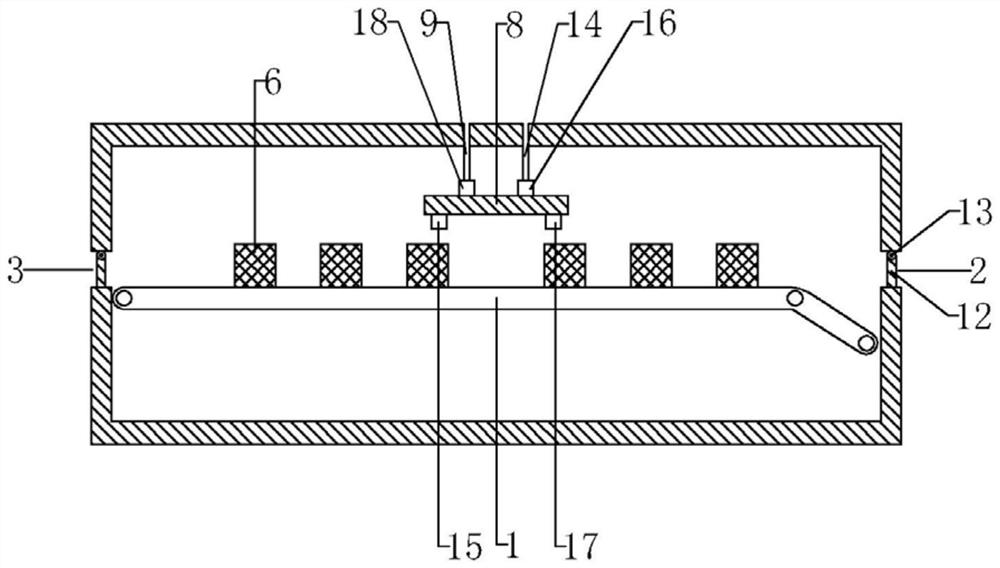

[0025] Embodiment 1 is basically as attached figure 1 - attached figure 2 Shown:

[0026] Air energy high temperature heat pump tunnel type multifunctional drying production equipment, as attached figure 1 - attached figure 2 As shown, it includes a conveyor belt 1, a feed port 2, and a discharge port 3, and a cuboid hollow drying box 4 is provided. The two relatively far side walls of the drying box 4 are respectively provided with a square feed port 2 and a square The discharge port 3, the feed port 2 and the discharge port 3 are respectively equipped with a heat diffusion prevention device, and the heat diffusion prevention device is provided with a square baffle plate 12 at the feed port 2, and the baffle plate 12 is surrounded by the side wall of the feed port 2. Clearance fit, the baffle 12 is connected to the top of the feed port 2 through the hinge 13, so that after the staff pushes the baffle 12, the baffle 12 can automatically return to its position under the ac...

Embodiment 2

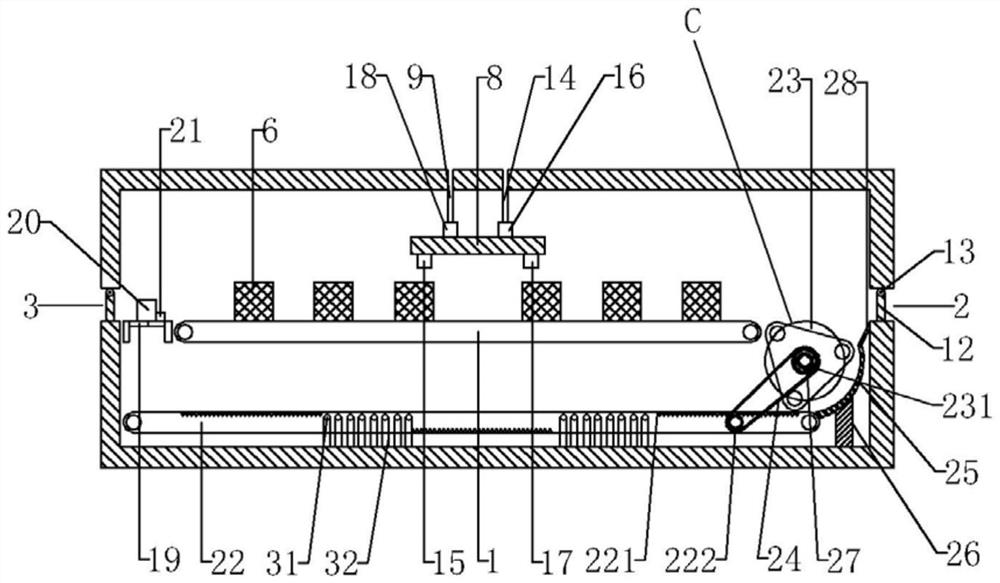

[0033] Embodiment 2 is basically as attached image 3 Shown:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com