A kind of electrochemical preparation method of rhodium trichloride

A rhodium trichloride, electrochemical technology, applied in the field of preparation of rhodium trichloride, can solve the problems of large loss of rhodium, complex process, low yield of rhodium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

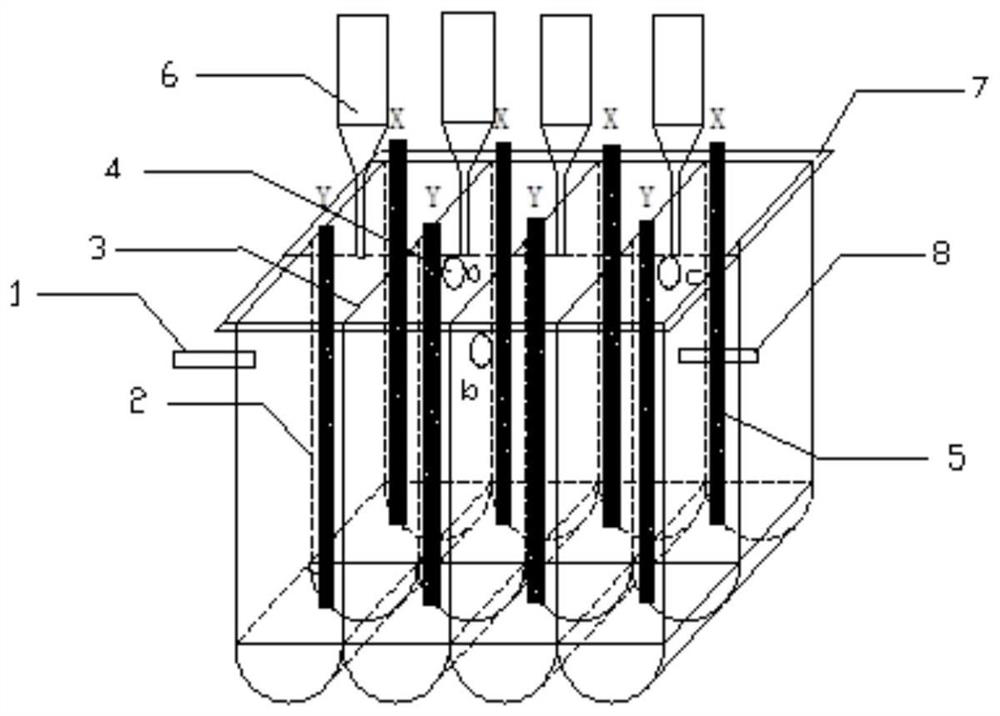

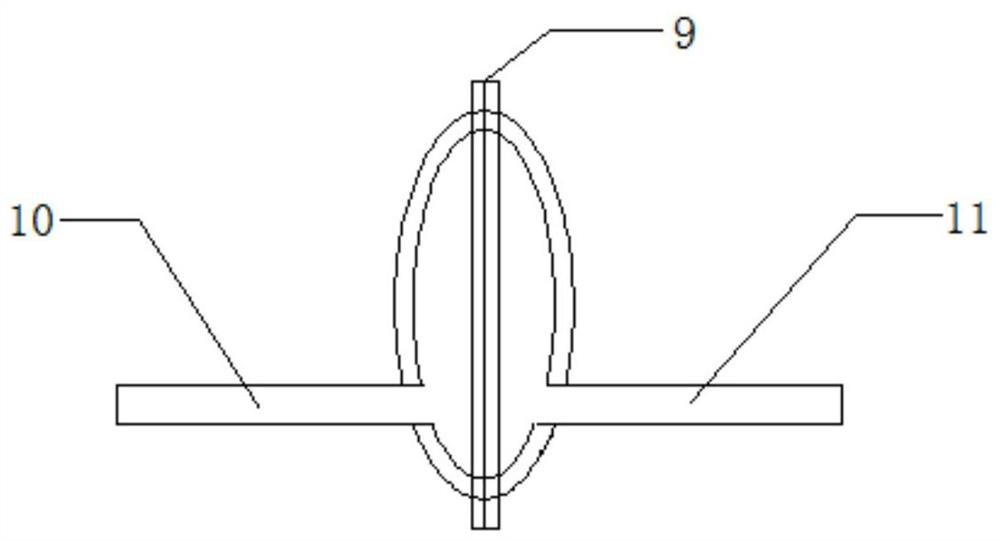

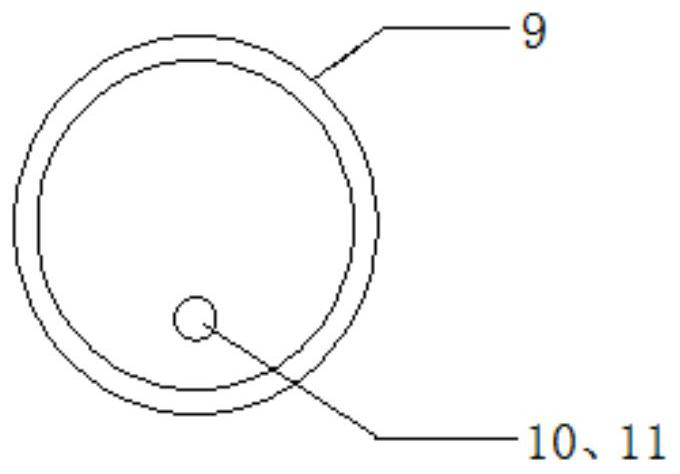

[0075] (1) Set up the electrolytic cell. The electrolytic cell has three groups of cells and six electrode chambers. The upper cross section of the cell body is rectangular in size 150mm×50mm and 300mm in height; the bottom of the two electrode chambers of the same cell body is a semicircle In the same way, there is a gap of 20mm from the top of the second partition; the overflow hole is opened at a position 50mm from the top, with a diameter of 10mm; a cylindrical graphite electrode with a spectral grade of Φ12mm and a length of 300mm is selected, a total of 12, fixed on the top cover, X, The distance between the Y electrodes is 100mm.

[0076] (2) 1200 grams of rhodium powder with a purity of 99.95% are evenly added to the bottom of the electrolytic cell, and the superior grade pure hydrochloric acid of 8mol / l is added from the feeding port until all tank bodies are filled; The end is loaded with 60 volts of civilian AC, and the AC current is between 10 and 30 amperes; pay a...

Embodiment 2

[0079] (1) Set up the electrolytic cell. The electrolytic cell has three groups of cells and six electrode chambers. The upper cross-section of the cell body is rectangular in size 160mm×45mm and 230mm in height; the bottom of the two electrode chambers of the same cell body is a semicircle In the same way, there is a gap of 20mm from the top of the second partition; the overflow hole is opened at a position of 30mm from the top, with a diameter of 10mm; a cylindrical graphite electrode with a spectral grade of Φ12mm and a length of 300mm is selected, a total of 12, fixed on the top cover, X, The distance between the Y electrodes is 100mm.

[0080](2) 1200 grams of rhodium powder with a purity of 99.95% are evenly added to the bottom of the electrolytic cell, and the superior grade pure hydrochloric acid of 10mol / l is added from the feeding port until all tank bodies are filled; The terminal is loaded with 50 volts of civilian alternating current, and the alternating current i...

Embodiment 3

[0083] (1) Set up the electrolytic cell. The electrolytic cell has three groups of cells and six electrode chambers. The upper cross-section of the cell body is rectangular in size 140mm×50mm and 320mm in height; the bottom of the two electrode chambers of the same cell body is a semicircular arc In the same way, there is a gap of 20mm from the top of the second partition; the overflow hole is opened at a position of 70mm from the top, with a diameter of 10mm; a cylindrical graphite electrode with a spectral grade of Φ10mm and a length of 300mm is selected, a total of 12, fixed on the top cover, X, The distance between the Y electrodes is 100mm.

[0084] (2) 1200 grams of rhodium powder with a purity of 99.95% are evenly added to the bottom of the electrolytic cell, and the superior grade pure hydrochloric acid of 8mol / l is added from the feeding port until all tank bodies are filled; The terminal is loaded with 70 volts of civilian alternating current, and the alternating cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com