Patents

Literature

68 results about "Rhodium(III) chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rhodium(III) chloride refers to inorganic compounds with the formula RhCl₃(H₂O)ₙ, where n varies from 0 to 3. These are diamagnetic solids featuring octahedral Rh(III) centres. Depending on the value of n, the material is either a dense brown solid or a soluble reddish salt. The soluble trihydrated (n = 3) salt is widely used to prepare compounds used in homogeneous catalysis, notably for the industrial production of acetic acid and hydroformylation.

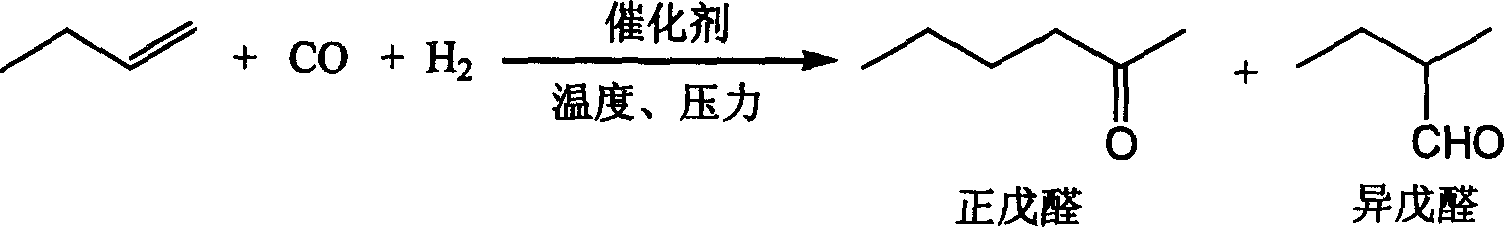

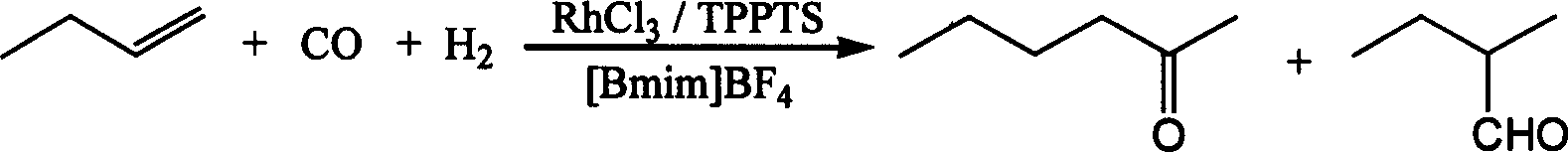

Preparing-1-pentanal from mixed solvent ion liquid of tetrafluorborate methyl buty I imidazole salt/water

InactiveCN1562932AGood choiceIncrease reaction ratePreparation by carbon monoxide reactionSolventIonic liquid

Prepn. of 1-valeric aldehyde by hydro-formylation of 1-butylene, carbon monoxid and hydrogen, catalyzed by rhodium trichloride and sodium m-triphenylphosphine trisulfonate, in mixed water solution of [Bmin] BF4. Then, the product is obtd. by gravitational settling and liquid separation. This method has advantages of: high yield, high selectivity, good prodn. environment and simple producing process. The product can be used as intermediate of perfumery, 1-pentoric acid and other fine chemicals.

Owner:EAST CHINA NORMAL UNIV

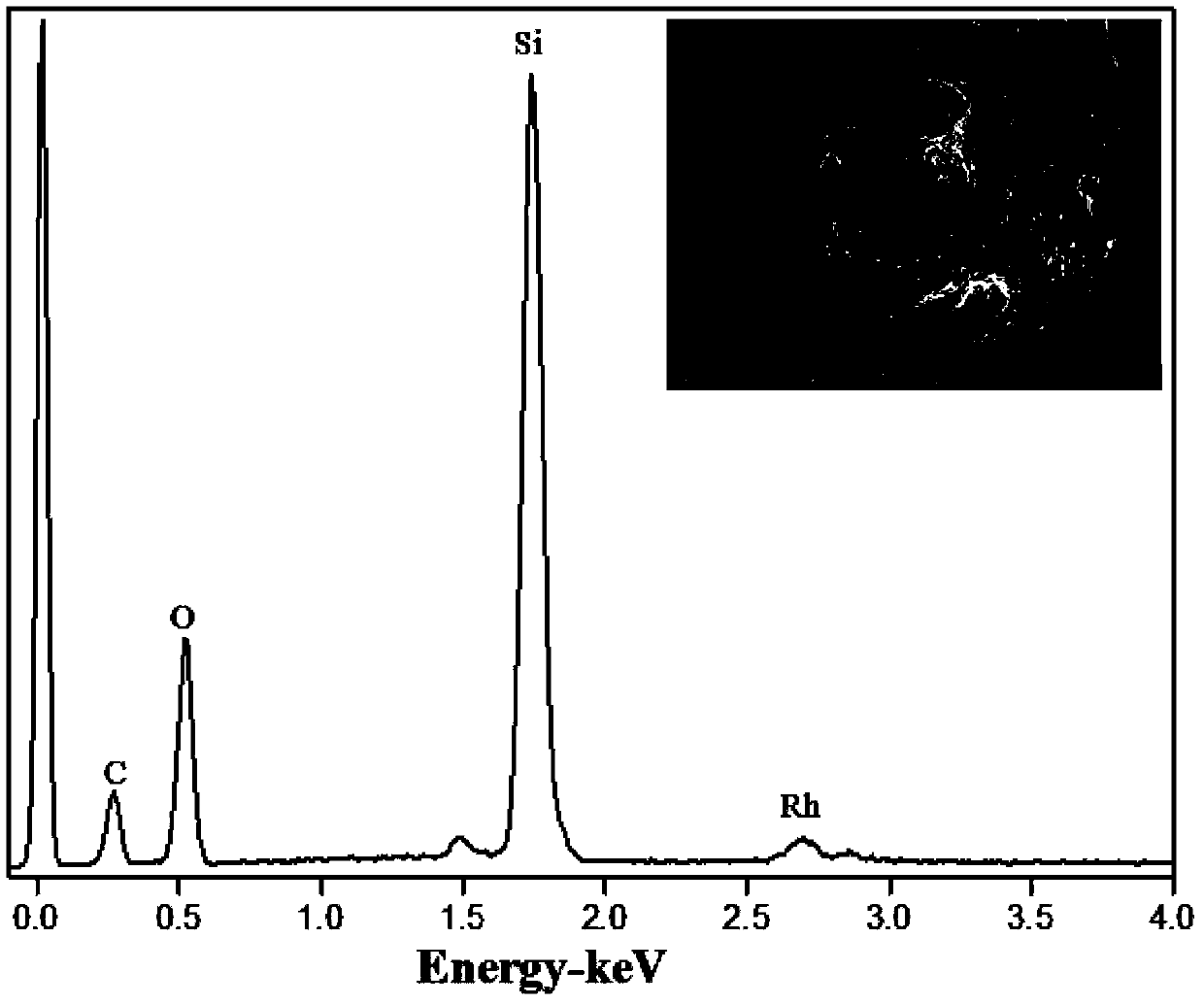

Preparation method of recyclable and reusable hydrogenation catalyst

ActiveCN103418439AEasy to makeEasy to storeCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenation reactionNitrogen

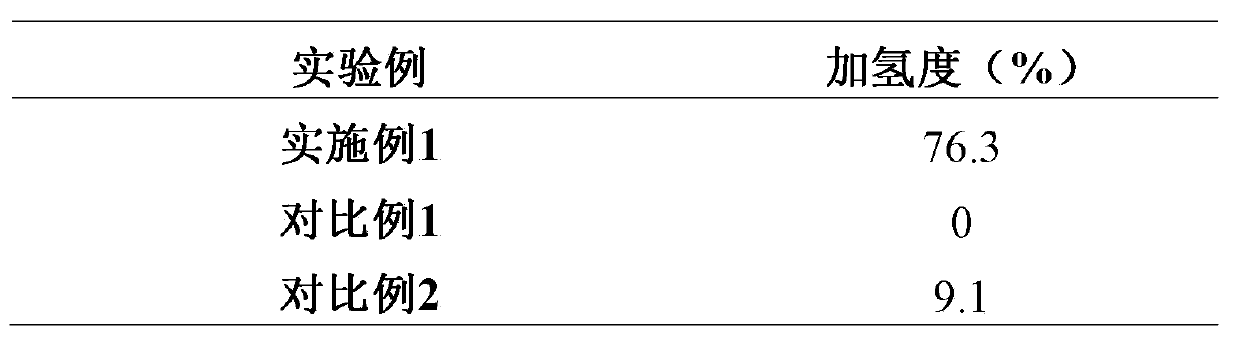

The invention relates to a preparation method of a recyclable and reusable hydrogenation catalyst. The preparation method is characterized by comprising the following steps: using a layer of poly dopamine to coat the surface of silicon dioxide, then adding an appropriate amount of deionized water as well as 0.5-500 mM rhodium chloride or ruthenium chloride or palladium chloride aqueous solution, performing reaction for 2-32 hours at the temperature of 20-100 DEG C, and performing oven-drying for 2-48 hours at the temperature of 25-75 DEG C to obtain a catalyst precursor; then adding 0.1%-20% of sodium borohydride aqueous solution, performing reaction for 1-24 hours at the temperature of 10-90 DEG C, and then performing oven-drying for 6-48 hours at the temperature of 10-90 DEG C to obtain the hydrogenation catalyst. The preparation method is simple in process, mild in reaction conditions and easy to operate; the hydrogenation catalyst has good stability to mediums such as air and water, and is simple in storage and processing manner; the operation of the hydrogenation catalyst does not need nitrogen protection; moreover, the hydrogenation reaction can be performed at lower temperature, the hydrogenation catalyst has a better hydrogenization effect after being used for 5 times in a recycling manner, and the recovery rate of the hydrogenation catalyst is more than 90%.

Owner:BEIJING UNIV OF CHEM TECH

Molten gold resisting high-temp sinter and its preparing process

A gold solution resisting high-temp sinter for ceramic decoration contains Au (10-15 wt.%), Th (2.2-3.0), Rh (0.1-0.3), Sb (0.1-0.8), Pb (0.3-0.4), Bi (1.0-1.4) and mixed solvent. It is prepared through preparing resinates of thorium nitrate, RhO3 and SbCl3, mixing them together; preparing gold ammonium percloride from AuCl3, reaction on balsam sulfide to obtain gold resinate; preparing resinatesof lead nitrate and bismuth nitrate, mixing them together; mixing said three components together, and diluting with mixed solvent.

Owner:NANJING UNIV

New method for synthesizing rhodium caprylate (II)

ActiveCN101891606AReduce pollutionQuick responseCarboxylic acid salt preparationChlorideReaction speed

The invention discloses a new method for synthesizing rhodium caprylate (II), which is characterized by comprising the following steps: dissolving a certain amount of rhodium chloride in water; adding 120 to 300 theoretical percent of octylic acid into the water, and adjusting the pH valve of the obtained solution to between 4.5 and 6.5 by using alkali; heating the solution to the temperature of between 90 DEG C and 100 DEG C, reacting for 3 to 5 hours, and filtering the solution when the solution is hot; and fully washing by using water, and drying to obtain a green rhodium caprylate (II) product. The method for synthesizing the rhodium caprylate (II) has the advantages of high reaction speed, high yield (over 95 percent), high product purity (over 99 percent), small environmental pollution, and suitability for industrial production.

Owner:GUIYAN DETECTION TECH YUNNAN CO LTD

Method for producing 3-(triphenylphosphine )-carbonyl hydrogenation Rh

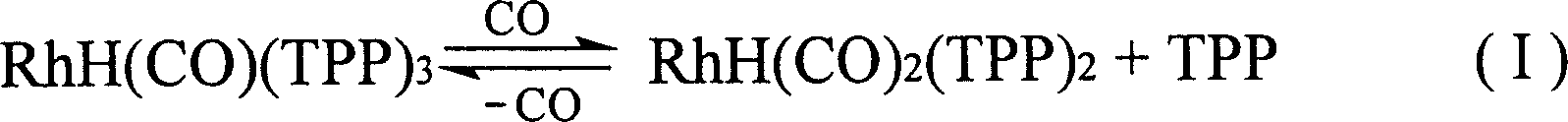

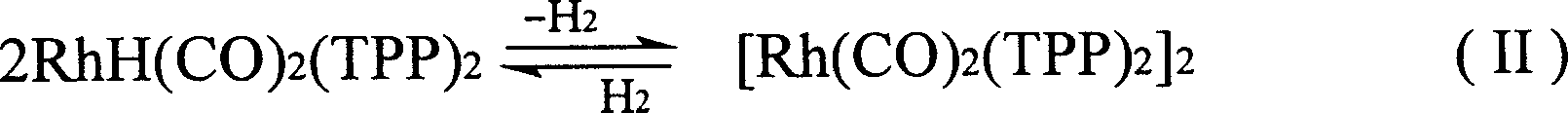

ActiveCN101172987AGood homogeneous catalytic activity for olefin hydroformylationOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsHydrogen atmosphereSolvent

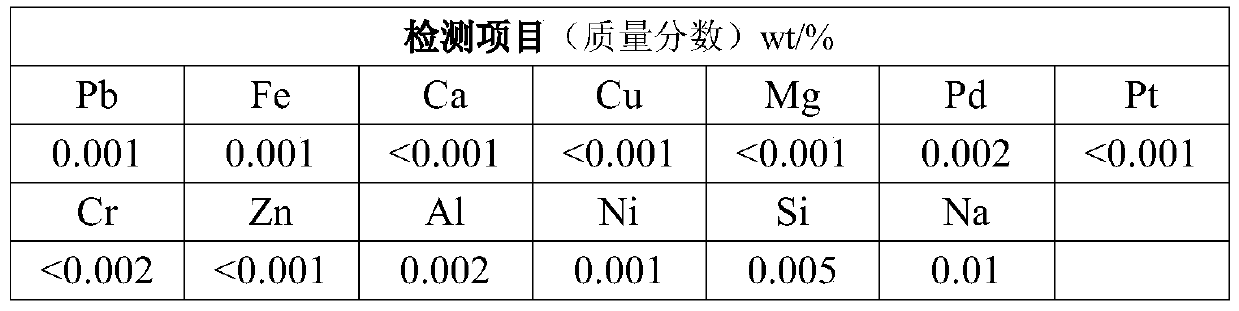

The invention relates to a preparation method of olefin hydrogen formylated homogeneous phase complex catalyst, in particular to the method of using rhodium chloride hydrate as raw material for preparing tri-(triphenyl phosphine) carbonyl hydrogenation rhodium. In the hydrogen atmosphere, alcohol-water component solvent is adopted, and rhodium chloride hydrate is adopted as raw material, and alkali metal hydrated oxide and borohydride mixture are adopted as deoxidizer to directly compose the objective product. Compared with the traditional method, the invention solves the problems of having low obtaining rate and big rhodium loss. The synthesis obtaining rate of tri-(triphenyl phosphine) carbonyl hydrogenation rhodium reaches more than 99 percent measured by rhodium content, and the toxical impurity content of element Cl is less than 0.02 percent. The homogeneous phase catalyst used for propylene hydrogen formylation aldehyde making reaction has good catalytic activity. The invention is applied to the organic chemical industry field.

Owner:CHINA PETROLEUM & CHEM CORP +1

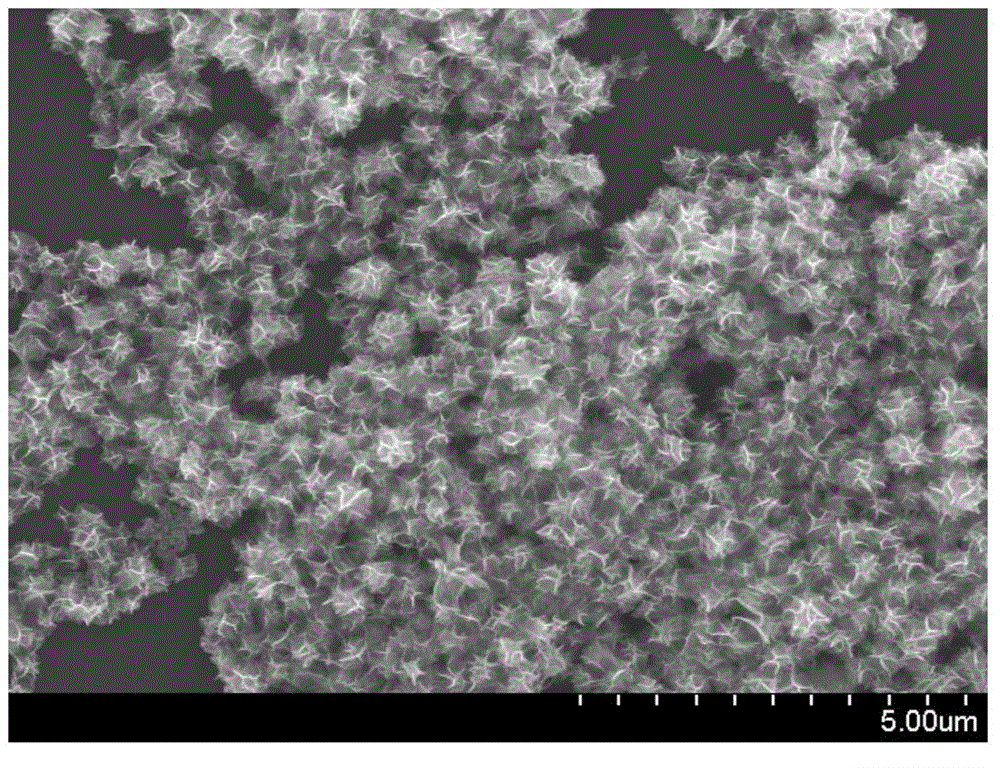

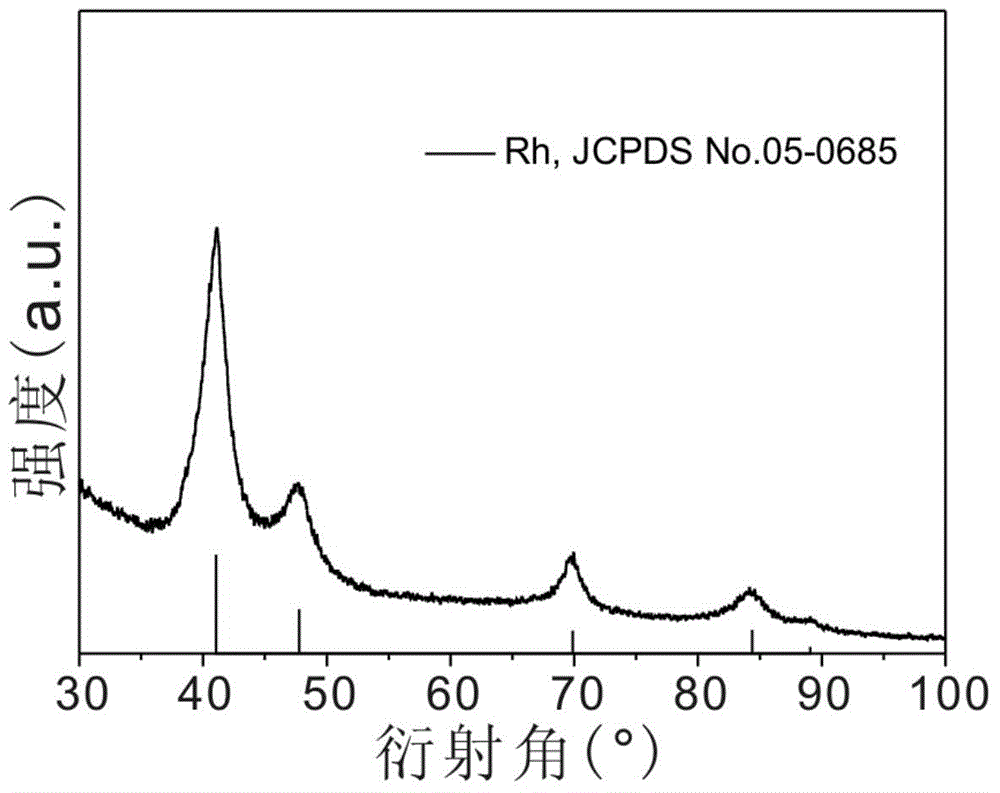

Rhodium nanometer catalyst as well as preparation method and application thereof

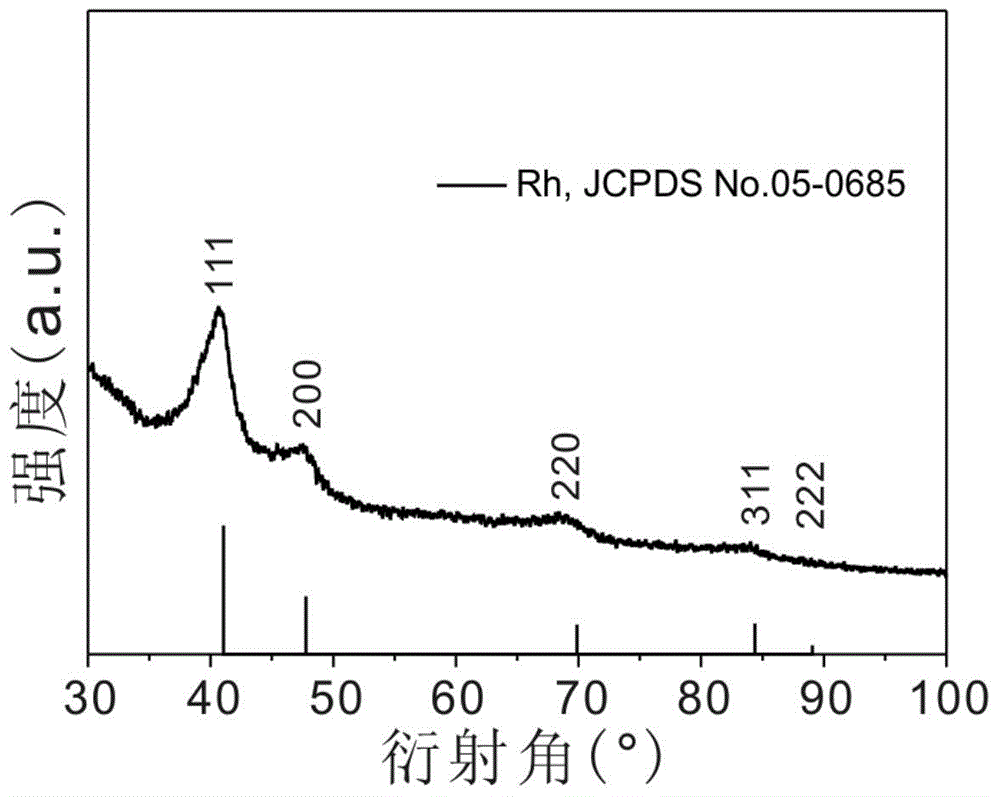

ActiveCN104549244AFine and uniform particlesImprove conversion rateHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNano catalystLevel structure

The invention relates to a rhodium nanometer catalyst as well as a preparation method and application thereof. The rhodium nanometer catalyst is a 100% rhodium nano-particle and a nanometer flower-like multi-level structure, wherein the thickness of the flower is 1.1nm. The preparation method comprises the following steps of placing a rhodium precursor, namely, rhodium acetylacetonate or rhodium trichloride into a reactor, adding deionized water, carrying out ultrasonic dispersion, adding a formaldehyde solution and reacting to obtain the rhodium nanometer catalyst. The rhodium nanometer catalyst can be applied in the hydrogenation reaction of cyclohexene. The preparation method is a one-step method and is simple in operation process and mild in reaction conditions. The solvent is environmentally friendly and has no environmental pollution. The subsequent processes such as crushing and ball milling are not needed and the rhodium nanometer catalyst can be directly used. During the use, the rhodium nanometer catalyst is hardly agglomerated and the active area loss of the catalyst is reduced. The rhodium nanometer catalyst has superior catalytic activity to the hydrogenation of cyclohexene, the usage amount of the catalyst is small, the reaction temperature is low and the reaction time is short.

Owner:XIAMEN UNIV

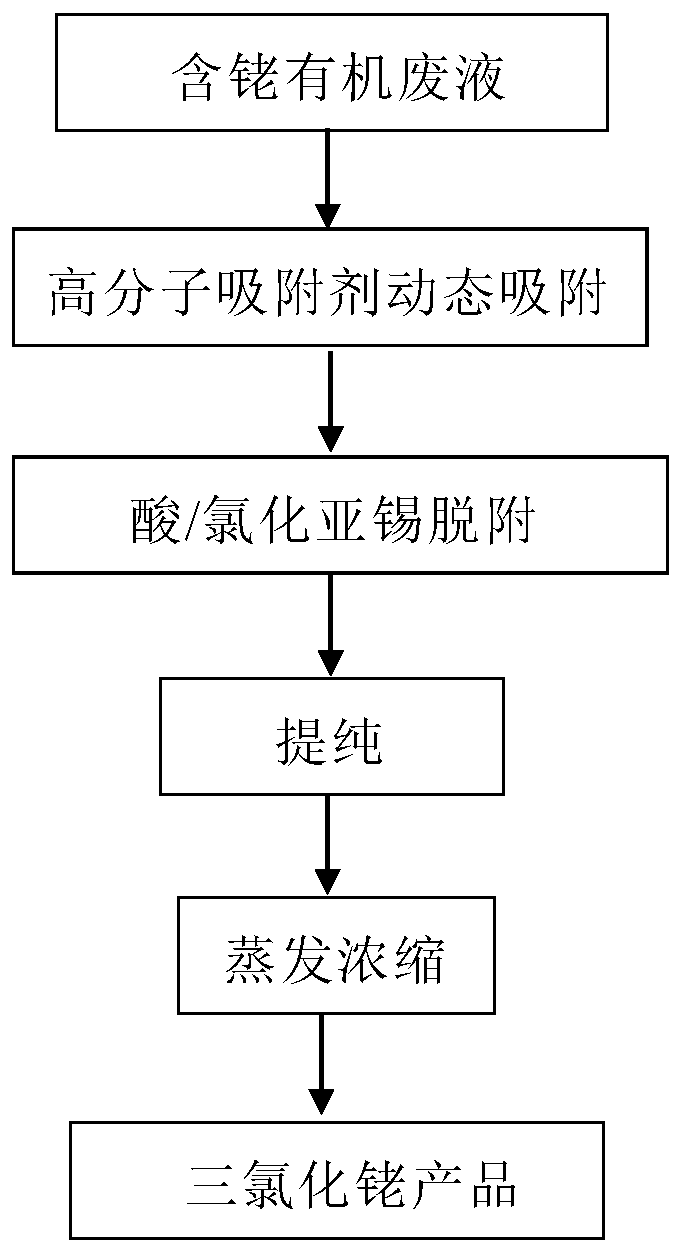

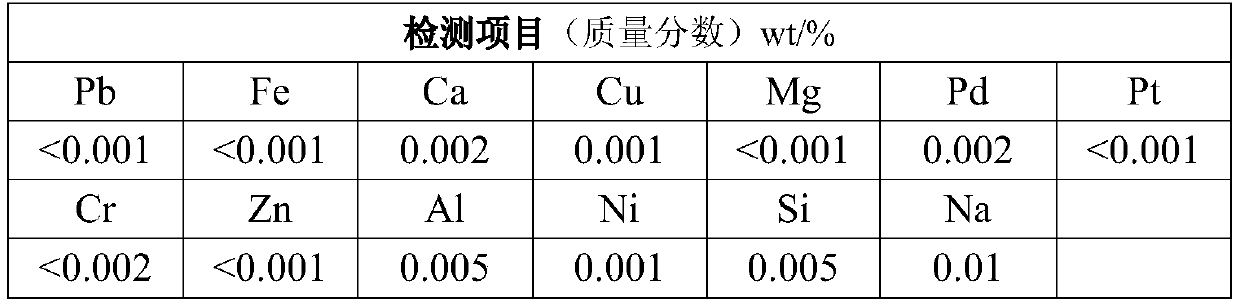

Method for recovering rhodium from rhodium-containing organic wastewater to prepare rhodium chloride

ActiveCN110607448ASimple and fast operationAccelerate the speed of entering the acidic solutionRuthenium/rhodium/palladium/osmium/iridium/platinum halidesRuthenium/rhodium/palladium/osmium/iridium/platinum compounds preparationFiltrationSorbent

The invention discloses a method for recovering rhodium from rhodium-containing organic wastewater to prepare rhodium chloride. The method includes the steps that first, a macromolecule adsorbent is adopted for adsorbing the rhodium in the rhodium-containing organic wastewater produced in the production process of a rhodium homogeneous catalyst onto an adsorbent in a dynamic adsorption mode; second, the rhodium-containing adsorbent is put into acid solvent, a certain amount of stannous chloride is added, backflow stirring is conducted, the rhodium is transferred into the solvent from the solidadsorbent, and a rhodium-containing aqueous phase solution is obtained by means of filtration; third, purification is performed; and fourth, the rhodium chloride is obtained through evaporation and concentration. The method is suitable for the rhodium-containing organic wastewater produced in the production process of the homogeneous catalyst, and the problem of recovering the rhodium from an organic phase is solved. The method is easy and simple to handle, no secondary exhaust gas and wastewater can be produced, going green and environmental protection are realized, and the recovery rate ofthe rhodium can reach 95% or above.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Method for preparing catalyst for addition reaction of hydrogen and silicon

InactiveCN101524651AEasy separationHigh selectivityGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsCoordination complexEthanol

The invention relates to a method for preparing rhodiumm chloride (1-(diphenylphosphine alkyl)-3-alkyl imidazole hexafluorophosphate), and aims to solve the technical problems that a series of catalyst for addition reaction of hydrogen and silicon is provided; the reaction is easy to carry out; the selectivity of a beta addition product in a product can be improved; and the catalyst can be recovered and reutilized. The method for preparing the catalyst is characterized in that 1-(diphenylphosphine alkyl)-3-alkyl imidazole hexafluorophosphate and rhodium chloride with the mol ratio of 3:1 are taken as a raw material, reflowed in ethanol, and are cooled to the room temperature; solid materials are filtered out; ethanol washing is carried out; and the rhodium chloride (1-(diphenylphosphine alkyl)-3-alkyl imidazole hexafluorophosphate) complex is obtained after vacuum drying.

Owner:HANGZHOU NORMAL UNIVERSITY

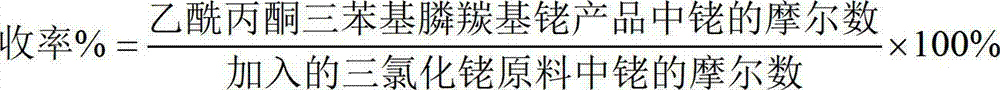

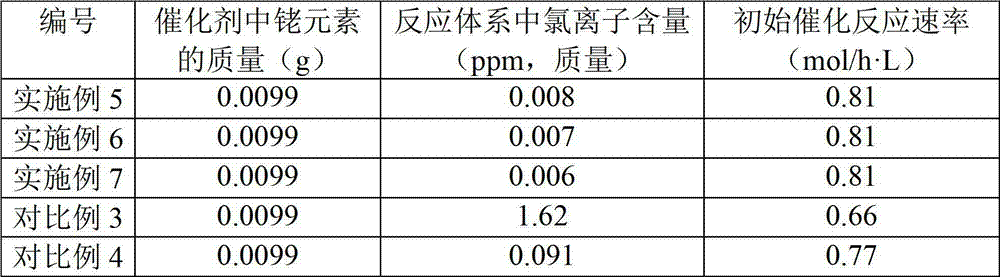

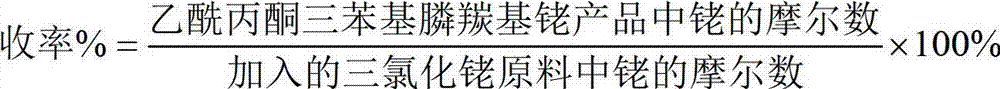

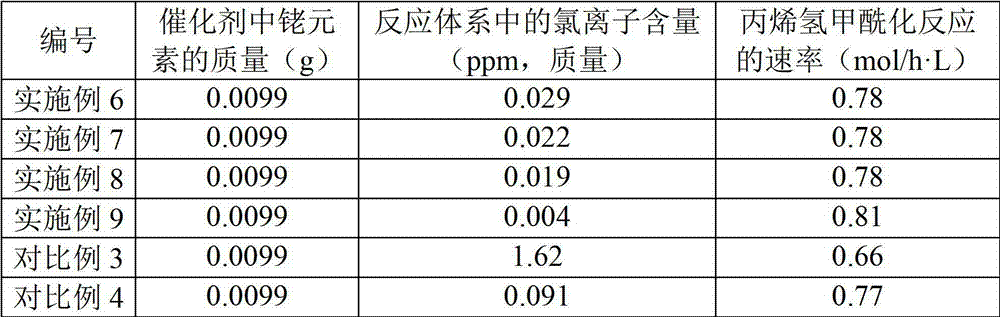

Preparation method of acetylacetonatocarbonyltriphenylphosphine rhodium, and olefin hydroformylation method

ActiveCN103709205AHigh synthetic yieldReduce contentPreparation by carbon monoxide reactionChlorideTriphenylphosphine

The invention discloses a preparation method of acetylacetonatocarbonyltriphenylphosphine rhodium. The preparation method comprises following steps: (1) under precipitation reaction conditions, a rhodium trichloride aqueous solution is contacted with a precipitating agent so as to precipitate rhodium and obtain a sediment containing rhodium; (2) the sediment containing rhodium is washed until chloride ion content is less than 1000ppm; (3) under acetylacetonato dicarbonylrhodium synthesis conditions, the sediment containing rhodium, which is obtained in step (2), is dissolved, and is contacted with acetylacetone so as to obtain a reaction liquid containing acetylacetonato dicarbonylrhodium; and (4) under acetylacetonatocarbonyltriphenylphosphine rhodium synthesis conditions, acetylacetonatocarbonyltriphenylphosphine rhodium in the reaction liquid is contacted with triphenylphosphine. The invention also discloses an olefin hydroformylation method. The preparation method of acetylacetonatocarbonyltriphenylphosphine rhodium is capable of reducing chloride ion content of products, increasing product synthesis yield, and improving catalytic activity of acetylacetonatocarbonyltriphenylphosphine rhodium.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of rhodium compounds

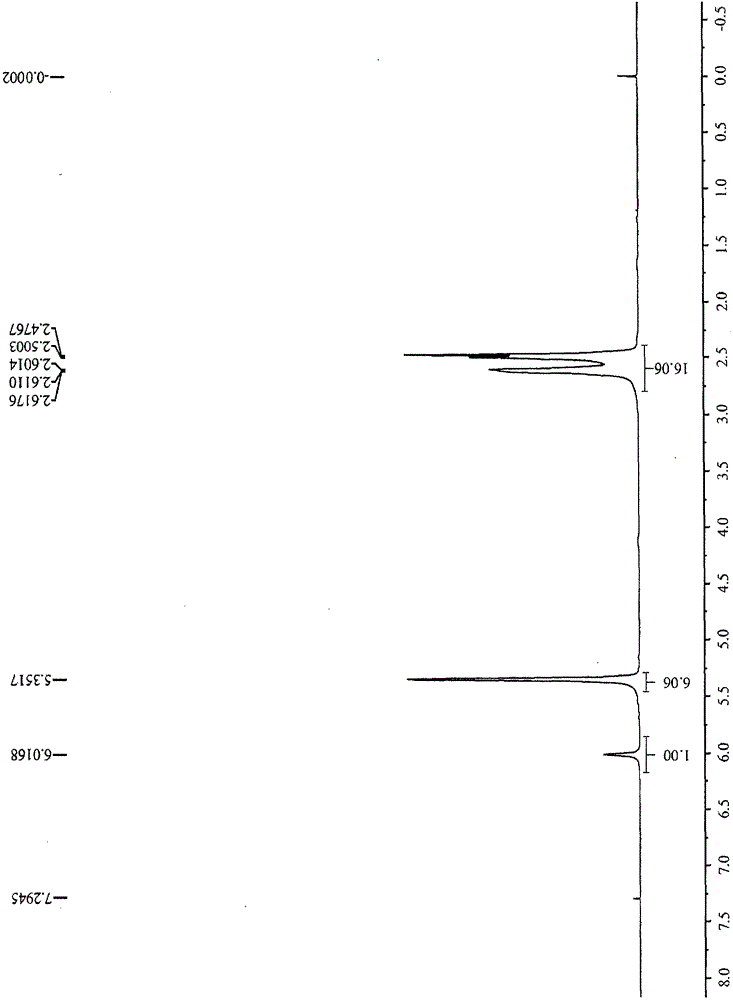

InactiveCN105585596AEasy to operateHigh purityRhodium organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsTetrafluoroborateDimmer

The invention discloses a preparation method of rhodium compounds. According to the method, bis(1.5-cyclooctadiene) rhodium(I) tetrafluoroborate compounds are synthesized in two steps, firstly, 1.5-cyclooctadiene rhodium chloride dimmers are synthesized with rhodium chloride trihydrate as raw materials; secondly, the bis(1.5-cyclooctadiene) rhodium(I) tetrafluoroborate compounds are synthesized with the 1.5-cyclooctadiene rhodium chloride dimmers as raw materials. The one-way total yield is 93% or above, operation is easy, industrial production can be achieved, and certain economic benefits are achieved.

Owner:JIANGXI HANS PRECIOUS METALS CO LTD

Method for reclaiming rhodium from waste rhodium catalyst of oxo synthesis reaction to prepare rhodium chloride hydrate

ActiveCN105314689AAvoid inertiaEasy to dissolve and prepareRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsNitrogen gasIon-exchange resin

The invention discloses a method for reclaiming rhodium from a waste rhodium catalyst of an oxo synthesis reaction to prepare a rhodium chloride hydrate. The method comprises the following steps: adding dimethyl formamide into a waste rhodium catalyst solution, uniformly stirring and mixing, and stepwise heating in the existence of nitrogen; collecting vapor by a condensing device, treating tail gas with a water spray absorption tower, diluting the residual liquid with ethanol, and filtering; washing the filter residues with ethanol to obtain a simple substance of active rhodium, adding concentrated hydrochloric acid and hydrogen peroxide into the simple substance of active rhodium, and dissolving to obtain a rhodium chloride solution; and removing iron, nickel, calcium and other impure ions with ionic exchange resin to obtain a refined chlororhodic acid solution, and concentrating and drying the refined chlororhodic acid solution to obtain high purity rhodium trichloride. The method has high efficiency, simple operation small rhodium loss and a rhodium yield of more than 99 percent.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Norbornene, styrene and maleic anhydride ternary polymerization catalyst and ternary polymerization method

The invention relates to a norbornene, styrene and maleic anhydride ternary polymerization catalyst and a ternary polymerization method. The norbornene, styrene and maleic anhydride ternary polymerization catalyst is characterized in that a preparation method of the catalyst comprises the steps of dissolving rhodium chloride, iethylzinc and a ligand compound into a first solvent in a single-neck glass bottle with a dry inert atmosphere, sealing the bottleneck, and keeping the constant temperature of 40-50 DEG C for 15-30 minutes to obtain a rhodium-zinc complex catalyst. The ternary polymerization method comprises the steps of adding norbornene monomers, styrenes and maleic anhydride monomers into the multiply vacuumized and dried single-neck glass bottle with the dry inert atmosphere according to the molar ratio of 1:1:1, and then, adding a second solvent to dissolve; and then, adding the rhodium-zinc complex catalyst, and reacting at the temperature of 20-90 DEG C for 1-8 hours. The catalyst provided by the invention is cheap and available in raw materials, capable of generating catalytic activity at a relatively low temperature, low in polymerization reaction temperature and high in catalytic efficiency; and in addition, the catalyst is easily washed and separated, and the yield of copolymers is high.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Method for preparing high purity rhodium trichloride by removing impurity from liquid phase digestion solution of waste rhodium catalyst

InactiveCN103526039AMild process conditionsEasy to operateProcess efficiency improvementDigestionImpurity

The invention discloses a method for preparing high purity rhodium trichloride by removing impurities from a liquid phase digestion solution of a waste rhodium catalyst. The method is characterized by comprising the following steps: step one, taking liquid phase digestion solution obtained by digesting waste rhodium catalyst for carbonyl synthesis with concentrated sulfuric acid and nitrate, adjusting to pH value to 1-5 by using sodium hydroxide, dropwise adding a sodium oxalate solution with stirring so that the solution becomes turbid, continuing adding the sodium oxalate solution until complete precipitation, stirring for 20-40 min and filtering to obtain the filtrate, wherein the concentration of sodium oxalate solution is 1-10 wt%; and two, directly heating the filtrate obtained in the step one or diluting the filtrate with deionized water by 10 times and heating to a boiling state, adjusting the pH value to 8 with 1%-15% sodium hydroxide solution, stirring and filtering to obtain a rhodium gel; and dissolving the rhodium gel in 6 mol / L hydrochloric acid, and evaporating, concentrating and drying the solution to obtain high-purity three rhodium trichloride. The method of the invention is applicable to recovery of noble metal rhodium from the waste rhodium catalyst from carbonyl synthesis, and is economical and environment-friendly; and the method has the advantages of mild reaction conditions, simple operation and easiness for industrialization.

Owner:CHINA NAT OFFSHORE OIL CORP +2

New method for synthesizing rhodium caprylate (II)

ActiveCN101891606BReduce pollutionQuick responseCarboxylic acid salt preparationChlorideReaction speed

The invention discloses a new method for synthesizing rhodium caprylate (II), which is characterized by comprising the following steps: dissolving a certain amount of rhodium chloride in water; adding 120 to 300 theoretical percent of octylic acid into the water, and adjusting the pH valve of the obtained solution to between 4.5 and 6.5 by using alkali; heating the solution to the temperature of between 90 DEG C and 100 DEG C, reacting for 3 to 5 hours, and filtering the solution when the solution is hot; and fully washing by using water, and drying to obtain a green rhodium caprylate (II) product. The method for synthesizing the rhodium caprylate (II) has the advantages of high reaction speed, high yield (over 95 percent), high product purity (over 99 percent), small environmental pollution, and suitability for industrial production.

Owner:GUIYAN DETECTION TECH YUNNAN CO LTD

Method for preparing high-purity rhodium trichloride from carbonyl-synthetic-reaction waste rhodium catalyst degradation solution

ActiveCN104402068AImplement extractionEfficient extractionRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsCatalyst degradationIon exchange

The invention discloses a method for preparing high-purity rhodium trichloride from a carbonyl-synthetic-reaction waste rhodium catalyst degradation solution. The method comprises: diluting a degradation solution obtained by using a sulfuric acid and nitric acid mixed solution or a sulfuric acid, nitric acid, hydrochloric acid and hydrogen peroxide mixed solution to degrade a carbonyl-synthesis waste rhodium catalyst, heating, adding excess water-soluble sulphurizing salt hot solution to precipitate rhodium, filtering, using a hydrochloric acid solution to washing the precipitate, adding a hydrochloric acid and hydrogen peroxide mixed solution to dissolve the precipitate, filtering, employing an ion exchange method known in the field to process the filtrate to remove Fe, Ni, Ca and other ionic impurities, concentrating and drying to obtain the high-purity rhodium trichloride.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

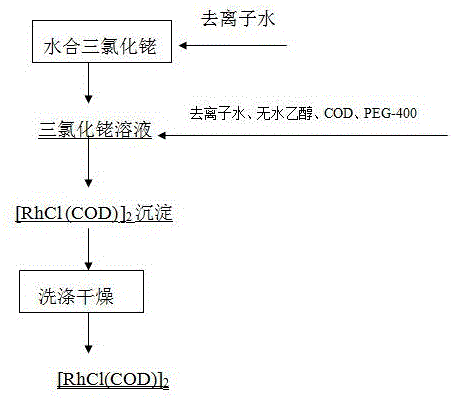

Preparation method of (1,5-cyclooctadiene) rhodium chloride (I) dimers

The invention provides a preparation method of (1,5-cyclooctadiene) rhodium chloride (I) dimmers. The method comprises the following concrete steps of (a) dissolving rhodium chloride hydrate by deionized water so that the rhodium concentration in the rhodium chloride water solution is 3 to 8 percent; putting the materials into a reaction kettle; connecting the upper end of the reaction kettle with a condensing pipe; adding absolute ethyl alcohol into the reaction kettle; performing heating, stirring and temperature rise; when the temperature rises to 35 DEG C, dripping a mixed solution of 1,5-cyclooctadiene COD and absolute ethyl alcohol; after the solution dripping is completed, adding a phase transfer catalyst PEG-400; performing reaction for 4 to 7 hours at 35 to 80 DEG C to obtain orange precipitates and suspension; performing filtering; (b) cooling the suspension in the step (a) to the room temperature; performing vacuum suction filtration to obtain a solid-state product; (c) washing and drying the solid-state product in the step (b). The product yield is 80 to 85 percent. By using the method, during the synthesis, the phase transfer catalyst PEG-400 is added, so that the raw materials and the ligand can be changed from two phases into one phase under the temperature reduction condition; the reaction temperature is reduced; the reaction temperature is reduced from 60 to 85 DEG C to 30 to 40 DEG C, but the reaction time cannot be prolonged.

Owner:JINCHUAN GROUP LIMITED

Method for recovering rhodium chloride from rhodium slag

ActiveCN111410242AHigh purityHigh yieldRuthenium/rhodium/palladium/osmium/iridium/platinum halidesProcess efficiency improvementFormateChloride

The invention relates to a method for recovering rhodium chloride from rhodium slag. The method comprises the steps of: performing rhodium ash pretreatment, rhodium ash acid pickling, acid salt melting of alkali metal, cationic resin adsorption, evaporative crystallization and formic acid reduction; pretreating rhodium ash by formate; performing re-pickling, washing away most base metals, after drying, uniformly mixing with acid salt of alkali metal and an auxiliary agent to form powder, and carrying out melting reaction in a muffle furnace; adding deionized water to leach a melt, enabling thetreated leach liquor to pass through cationic resin, thoroughly removing base metals, performing concentrating and drying to obtain high-purity rhodium trichloride, eluting the resin by using hydrochloric acid after the resin adsorbs iron to be saturated, and adding formic acid into the eluent to reduce rhodium, thereby realizing separation of rhodium and iron in the resin eluent. The invention aims to provide a method for recovering rhodium chloride from rhodium slag, which has the advantages of simple recovery technique, no environmental pollution and high rhodium chloride purity for rhodium chloride recovery.

Owner:LUXI CATALYST

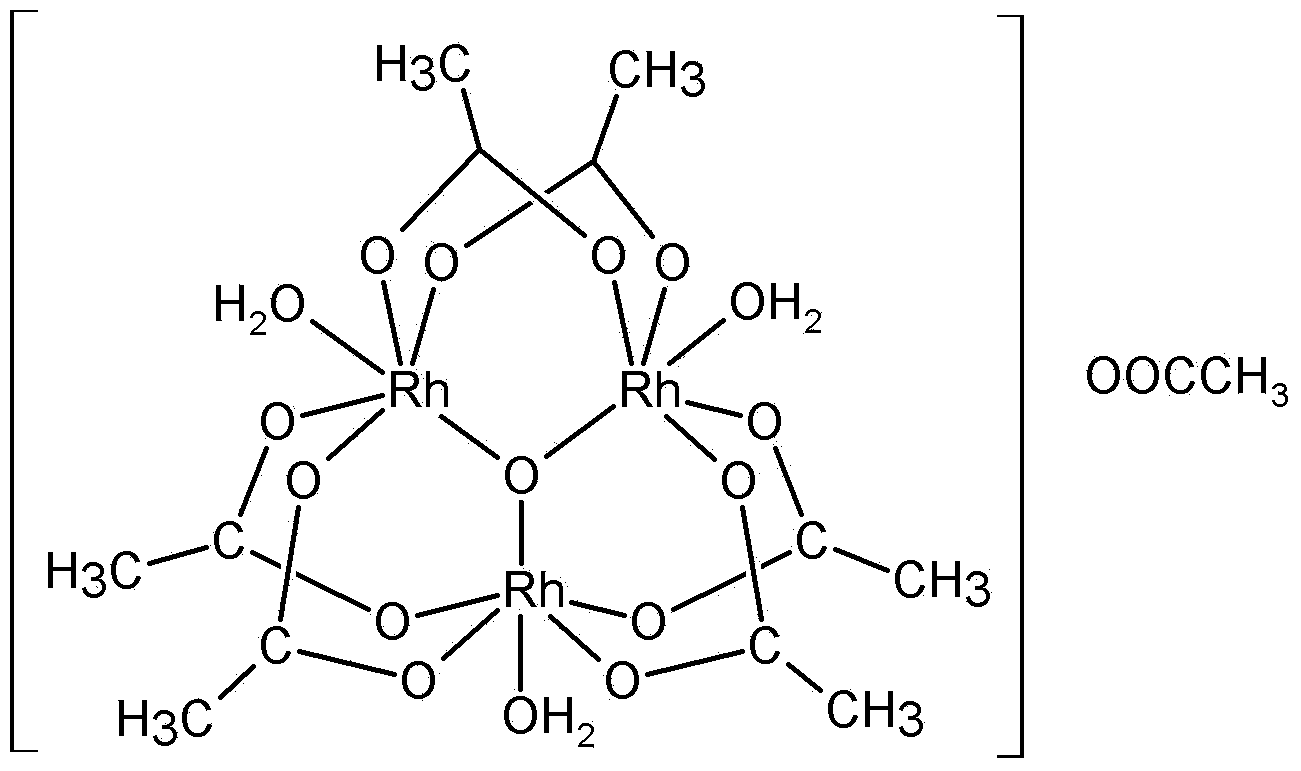

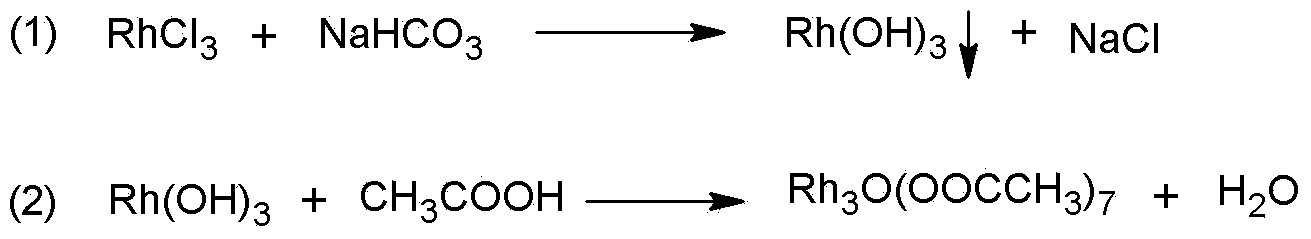

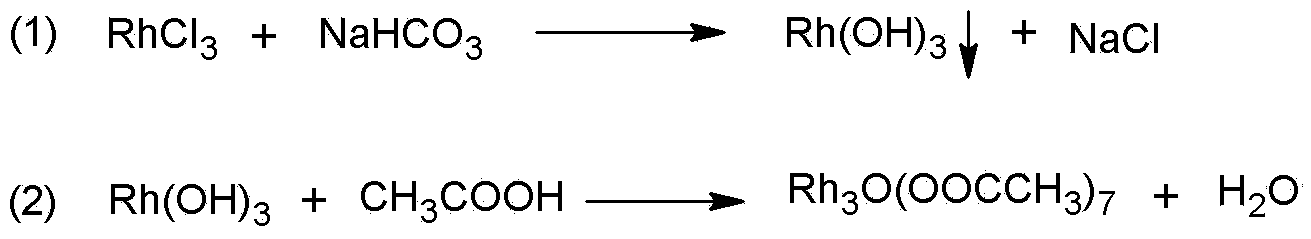

Synthesis method of tri-nuclear rhodium acetate (III)

ActiveCN103880888ANo generationEasy to operateGroup 8/9/10/18 element organic compoundsHydration reactionSodium bicarbonate

The invention relates to a novel method for synthesizing trivalent rhodium acetate (III). The method is characterized by comprising the following two steps: (1) dissolving a certain amount of rhodium trichloride hydrate in proper amount of distilled water, adding a sodium hydrogen carbonate water solution according to a stoichiometric ratio, stirring and reacting for 1-2 hours at 20-60 DEG C, and filtering to obtain a yellow rhodium hydroxide solid; (2) stirring and reacting the rhodium hydroxide solid and glacial acetic acid which is 1-5 times as much as a stoichiometric ratio of the rhodium hydroxide solid at 50-100 DEG C for 2-4 hours, filtering, concentrating filtrate to be dry, and drying to obtain a tri-nuclear rhodium acetate (III) product. The tri-nuclear rhodium acetate (III) product is prepared by the method from common rhodium trichloride hydrate through a two-step reaction. The synthesis method disclosed by the invention is simple to operate, high in reaction yield (more than 90%), nearly free from byproduct in reaction and high in product purity (more than 99.0%); the synthesis method is applicable to industrial production.

Owner:KUNMING INST OF PRECIOUS METALS

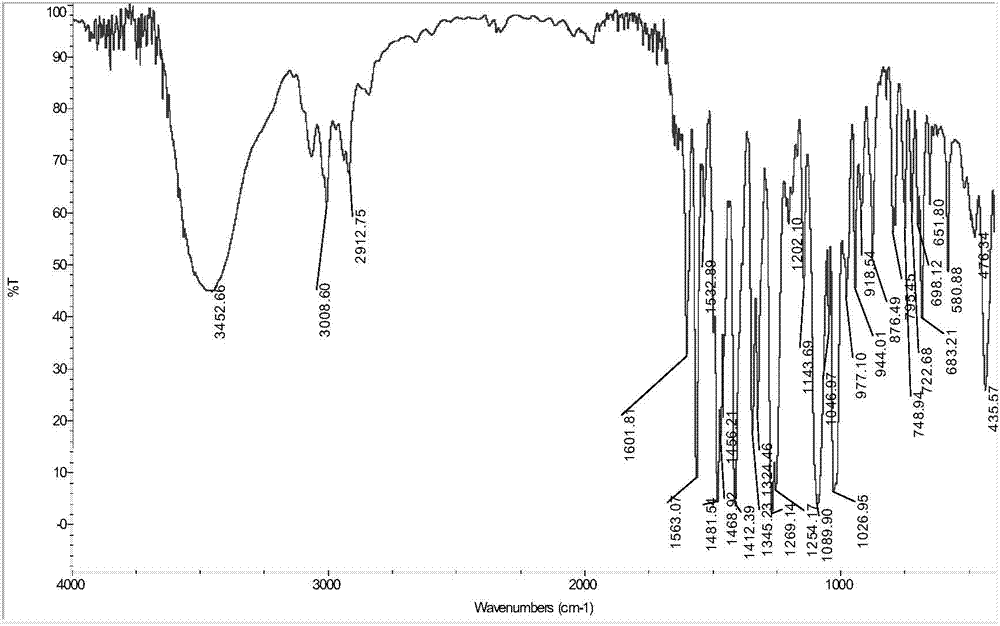

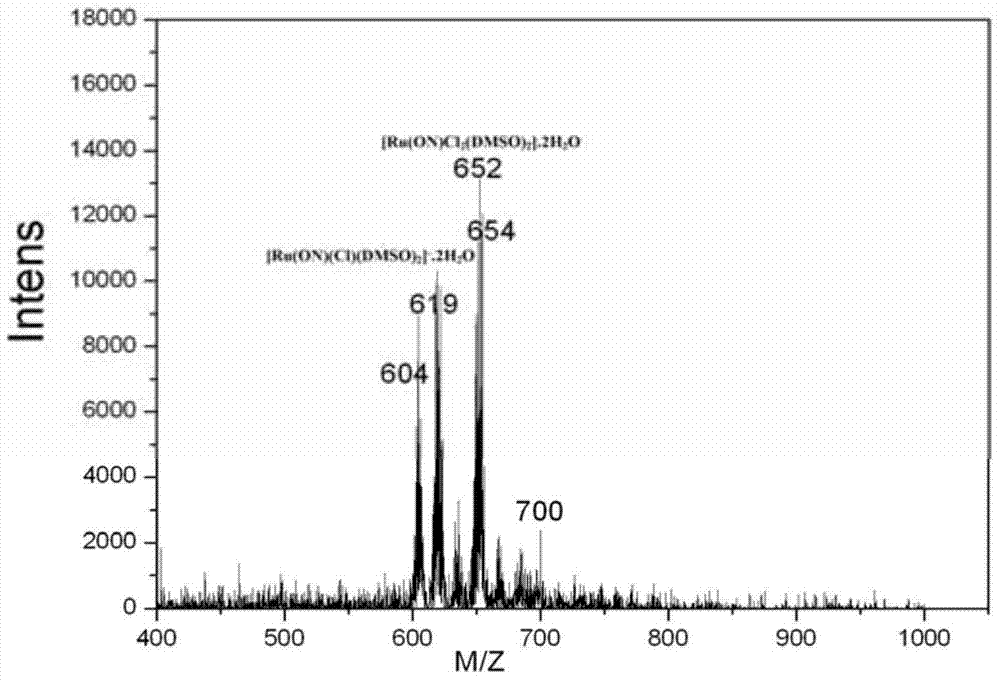

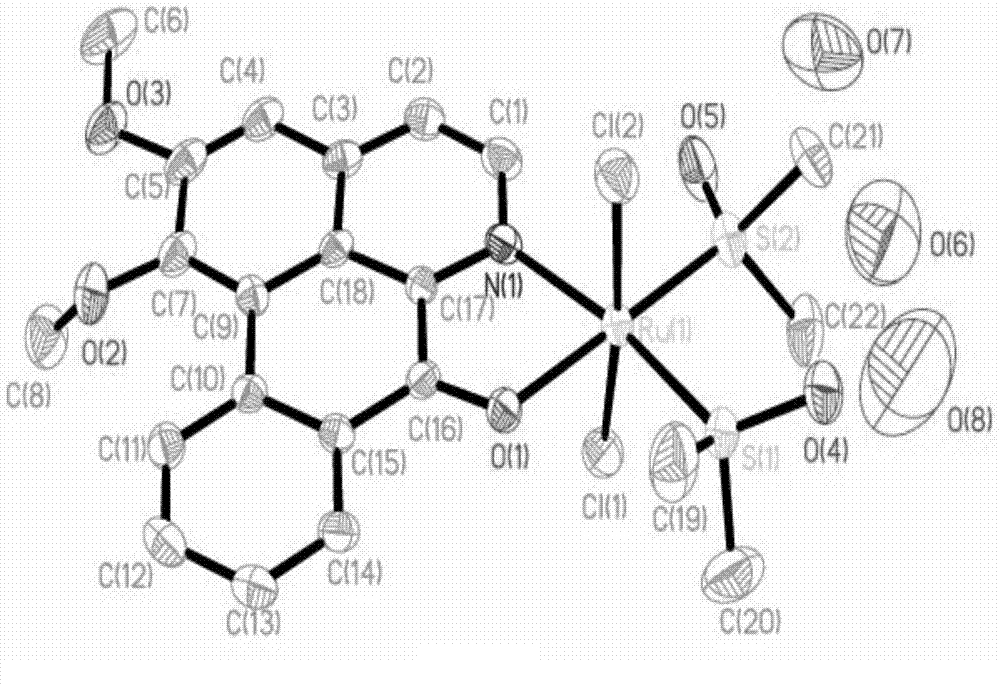

Ruthenium and rhodium metal complexes taking lysicamine as ligands as well as synthetic method and application of ruthenium and rhodium metal complex

InactiveCN104744520AReduced activitySignificant in vitro antitumor activityOrganic active ingredientsRuthenium organic compoundsCytotoxicityStructural formula

The invention discloses two novel ruthenium and rhodium metal complexes taking lysicamine as ligands as well as a synthetic method and application of the two novel ruthenium and rhodium metal complexes. The synthetic method of the ruthenium and rhodium metal complexes comprises the following steps: dissolving dichloro.tetra(dimethyl sulfoxide) ruthenium (II) or rhodium trichloride and lysicamine into a polar solvent, and performing complexation reaction to prepare the ruthenium and rhodium metal complexes, wherein the ruthenium and rhodium metal complexes can be synthesized by virtue of solution methods or solvothermal methods. After the applicants investigate the proliferation inhibition activity of the ruthenium and rhodium metal complexes on human tumor cell lines such as NCI-H460, HepG-2, DLD-1 and MGC80-3 and the toxicity of the ruthenium and rhodium metal complexes to human normal liver cells HL-7702, results show that the ruthenium and rhodium metal complexes have significant in-vitro anti-tumor activity, and the activity of a rhodium metal complex is equal to that of cis-platinum; moreover, the ruthenium and rhodium metal complexes have relatively low cytotoxicity to normal cells, have good potential medicinal values, and are expected to be applied to the preparation of various anti-tumor medicines; and structural formulas of the complexes are respectively shown in the following formula (I) and formula (II) in the specification.

Owner:GUANGXI NORMAL UNIV

Rhodium/nickel alloy nano-catalyst, preparation method and application thereof

ActiveCN107442134AGood dispersionHigh catalytic activityOrganic chemistryOrganic compound preparationNano catalystReaction temperature

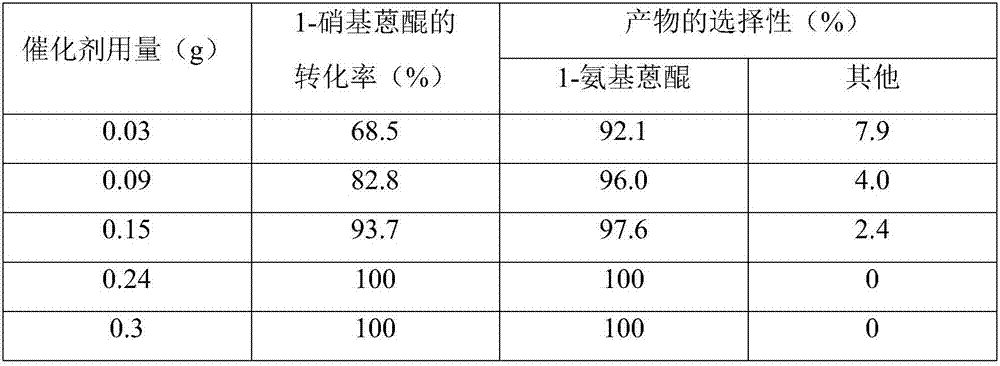

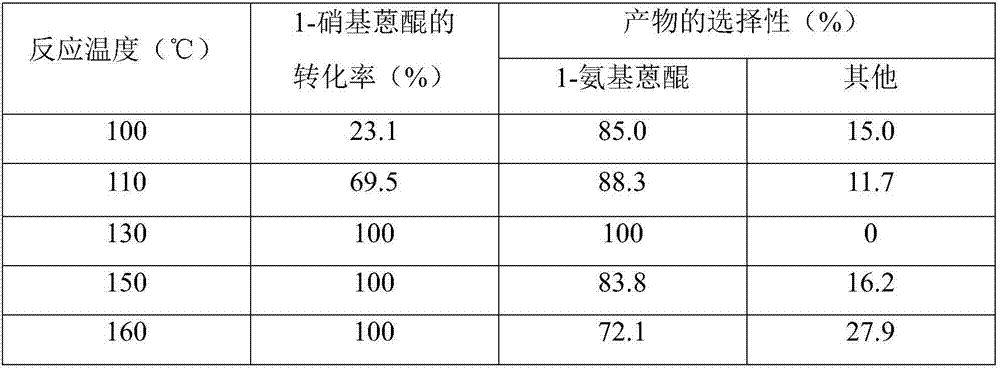

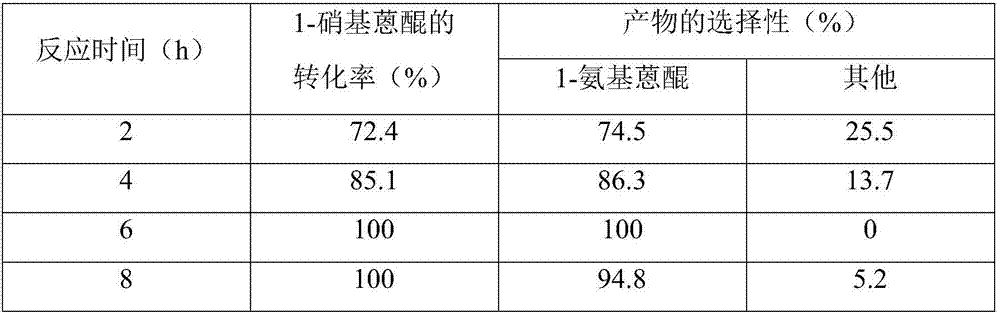

The invention relates to a rhodium / nickel alloy nano-catalyst, a preparation method and an application thereof and belongs to the field of nano-catalyst research. The catalyst provided by the invention is a spherical and polyhedral rhodium / nickel alloy nano-particle; the size direction of the prepared rhodium / nickel alloy nano-catalyst particle is 12-58nm; and the molar ratio of rhodium to nickel in the catalyst is at (0.01-0.05):1. According to the invention, nickel acetate and rhodium chloride are taken as raw materials for preparing the rhodium / nickel alloy nano-catalyst with different grain sizes and microstructures, and then 1-nitroanthraquinone and hydrogen are taken as raw materials and the catalyst is adopted for reacting, the reaction temperature is increased to 100-160 DEG C and the heat-insulating reaction is performed for 2-8h, so that high-purity 1-amino anthraquinone can be acquired. The dosage of the catalyst prepared according to the invention is less; the catalyst has higher catalytic activity and stability; and the method for preparing 1-amino anthraquinone by adopting the catalyst is simple in process requirement, is green and environmentally friendly and meets the industrial requirement.

Owner:JIANGSU UNIV

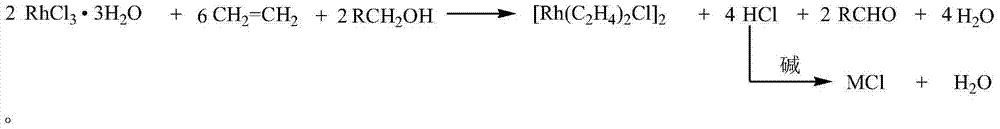

Method for synthesizing di(ethylene) chlorine rhodium (I) dimer

ActiveCN103896989AEfficient synthesisHigh yieldGroup 8/9/10/18 element organic compoundsNitrogen gasSolvent

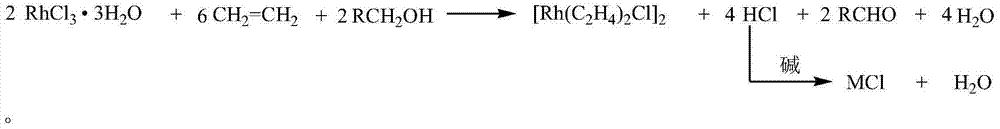

The invention discloses a method for synthesizing di(ethylene) chlorine rhodium (I) dimer. The method comprises the following steps: firstly, adding a certain amount of water which is as much as 1-10 times of the mass of rhodium trichloride hydrate into rhodium trichloride hydrate in a high-pressure reaction kettle, wherein the dissolving temperature is 50-80 DEG C; after rhodium trichloride hydrate is completely dissolved, adding C1-C3 alcohol used as a solvent which is as much as 10-50 times of the mass of rhodium trichloride hydrate, inside the high-pressure reaction kettle, heating and stirring to react taking ethylene of one barometric pressure instead of high pressure ethylene as a reactant, pressurizing to react for 0.5-2 hours, pressing a degassed alkali solution, continuously reacting for 0.5-1 hours, after the reaction is accomplished, releasing the ethylene inside the high pressure kettle, replacing the ethylene by using nitrogen, filtering and washing a reaction mixture in water and alcohol in the presence of nitrogen, and drying in vacuum at the room temperature so as to obtain the nacarat di(ethylene) chlorine rhodium (I) dimmer. The method has the characteristics that the synthesis yield can be increased, the cost is lowered, the reaction time is shortened, the operation process is simplified and the like.

Owner:浙江微通催化新材料有限公司

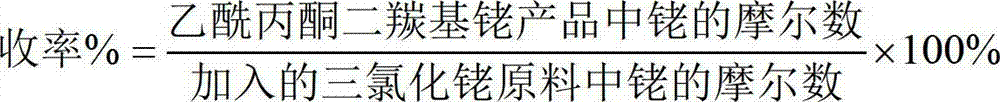

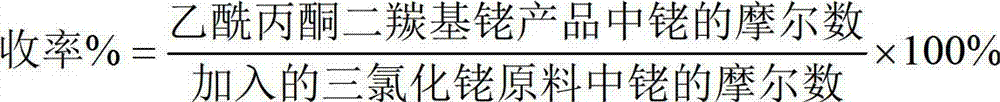

Preparation method of acetylacetonato dicarbonylrhodium, and olefin hydroformylation method

ActiveCN103709201AOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsIon contentChloride

The invention discloses a preparation method of acetylacetonato dicarbonylrhodium. The preparation method comprises following steps: (1) under precipitation reaction conditions, a rhodium trichloride aqueous solution is contacted with a precipitating agent so as to precipitate rhodium and obtain a sediment containing rhodium; (2) the sediment containing rhodium is washed until chloride ion content is less than 1000ppm; and (3) under acetylacetonato dicarbonylrhodium synthesis conditions, the sediment containing rhodium, which is obtained in step (2), is dissolved, and is contacted with acetylacetone. The invention also discloses an olefin hydroformylation method. The preparation method of acetylacetonato dicarbonylrhodium is capable of reducing chloride ion content of products, increasing product synthesis yield, and improving catalytic activity of acetylacetonato dicarbonylrhodium.

Owner:CHINA PETROLEUM & CHEM CORP +1

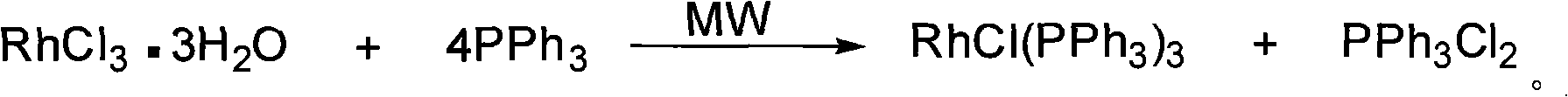

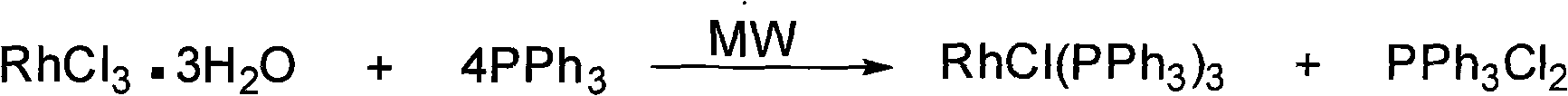

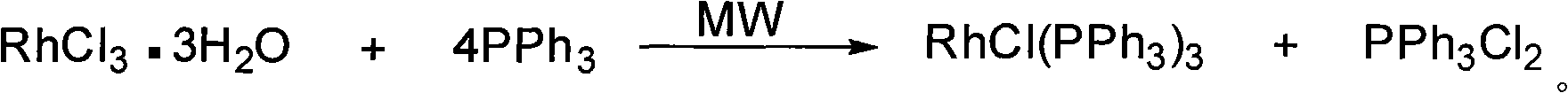

Microwave synthetic method of tri(triphenylphosphine) rhodium chloride

ActiveCN101353359AQuick responseLess solventGroup 8/9/10/18 element organic compoundsGroup 5/15 element organic compoundsAlcoholChloride

The invention relates to a method for synthesizing rhodium chloride (triphenylphosphine). The method of the invention takes rhodium chloride trihydrate and triphenylphosphine with the mass ratio of 1:5 to 5 as main raw materials for synthesizing the rhodium chloride (triphenylphosphine) rhodium in an alcohol-water mixed solvent under the condition of microwave radiation, wherein, the microwave radiation power ranges from 100 to 1000W, microwave reaction time lasts for 5 to 30 minutes, and the reaction formula is as the formula. The method has the advantages of high heating speed, short reaction time, high reaction yield, simple and convenient reaction operation, simple treatment after reaction and simplified process flow, etc.

Owner:浙江微通催化新材料有限公司

Method for preparing bis(norbornadiene)rhodium tetrafluoroborate

ActiveCN111087274AEasy to prepareEasy to operateHydrocarbon purification/separationHydrocarbonsSilver tetrafluoroborateTetrafluoroborate

The invention belongs to the technical field of precious metal preparation, and relates to a method for preparing bis(norbornadiene)rhodium tetrafluoroborate. A red bis(norbornadiene)rhodium tetrafluoroborate solid is obtained by subjecting rhodium trichloride hydrate and norbornadiene serving as raw materials to an ion exchange reaction with silver tetrafluoroborate in an inert gas protection environment and carrying out filter pressing. The preparation method is simple, the yield and the purity of a bis(norbornadiene)rhodium product are improved, and production cost is reduced.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

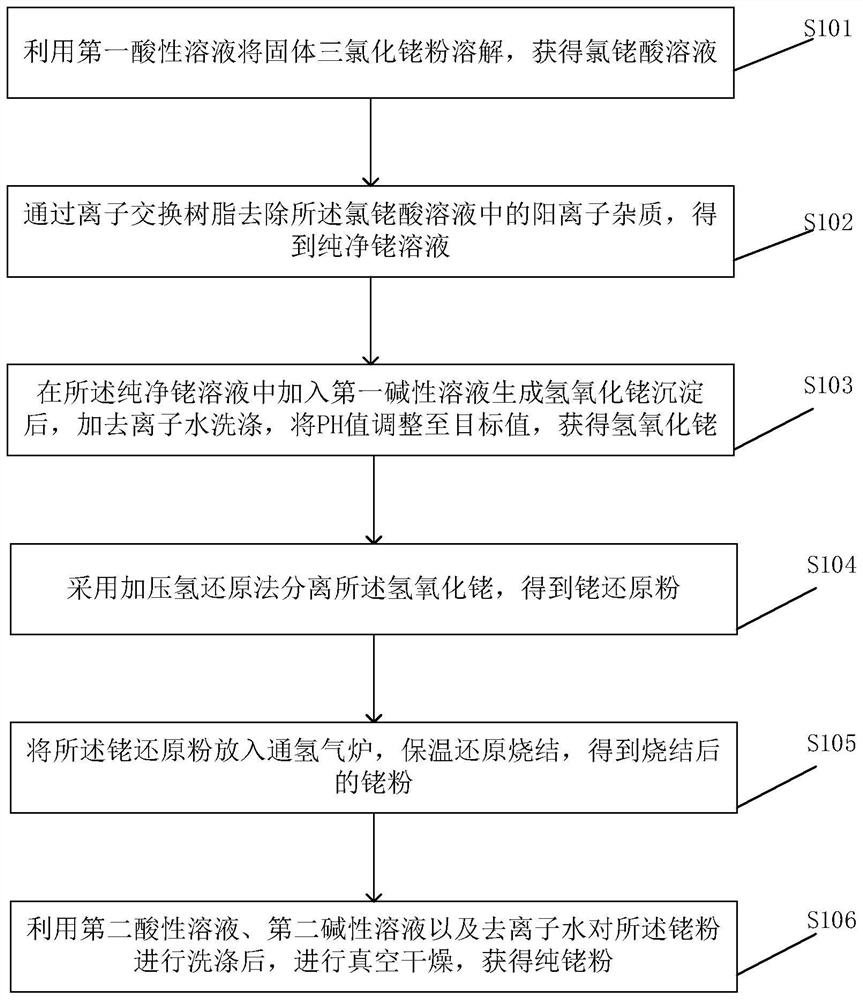

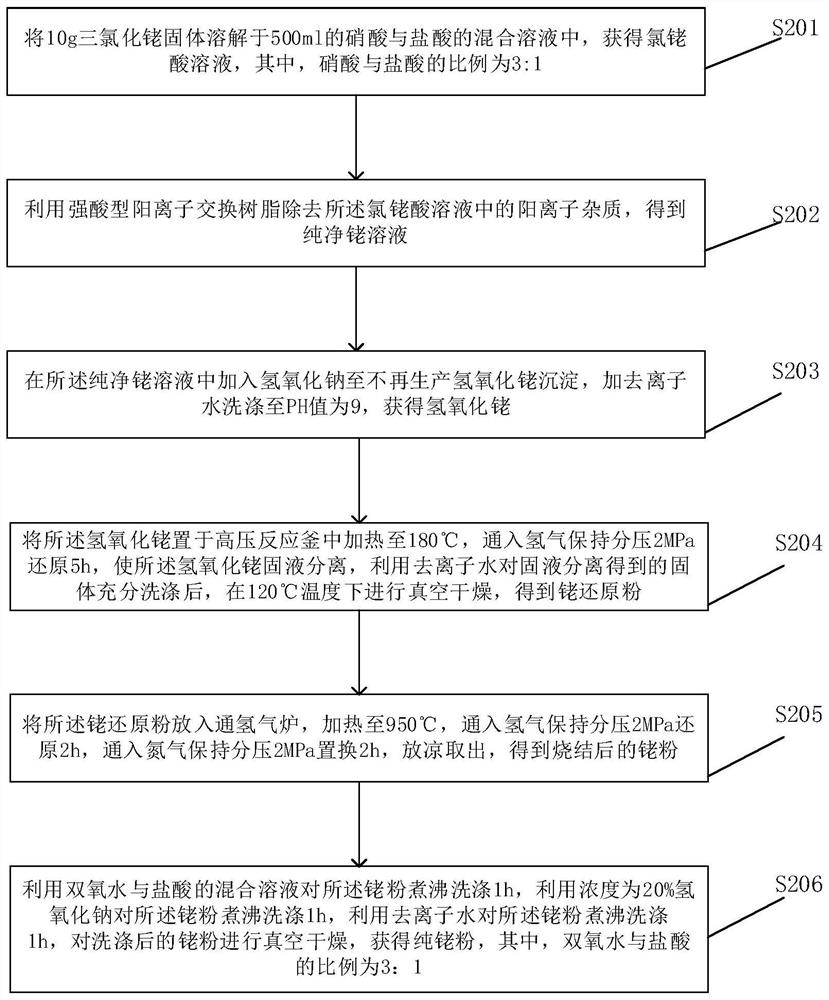

Method for preparing high-purity rhodium powder through rhodium trichloride

PendingCN113020615AMeet production requirementsIncrease productivityTransportation and packagingMetal-working apparatusPhysical chemistryIon exchange

The invention discloses a method for preparing high-purity rhodium powder through rhodium trichloride. The method comprises the following steps of dissolving solid rhodium trichloride powder by using a first acid solution to obtain a chlororhodium acid solution; removing cation impurities in the chlororhodium acid solution through ion exchange resin, and obtaining a pure rhodium solution; adding a first alkaline solution into the pure rhodium solution to generate rhodium hydroxide precipitate, adding deionized water for washing, and adjusting the pH value to a target value to obtain rhodium hydroxide; separating the rhodium hydroxide by adopting a pressurized hydrogen reduction method to obtain rhodium reduction powder; putting the rhodium reduction powder into a hydrogen introducing furnace, performing heat preservation reduction sintering, and obtaining sintered rhodium powder; and washing the rhodium powder by using a second acid solution, a second alkaline solution and deionized water, and carrying out vacuum drying to obtain the pure rhodium powder. According to the method provided by the invention, the preparation efficiency of the rhodium powder and the purity of the refined rhodium powder are improved.

Owner:CNOOC TAIYUAN PRECIOUS METALS

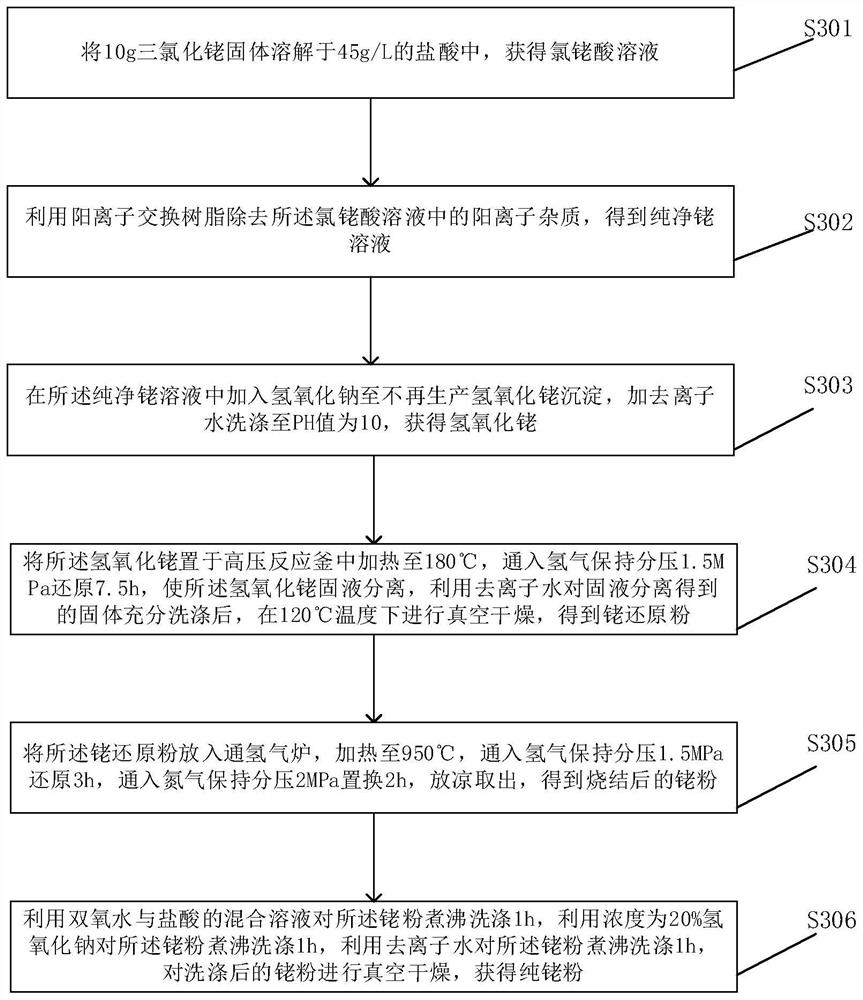

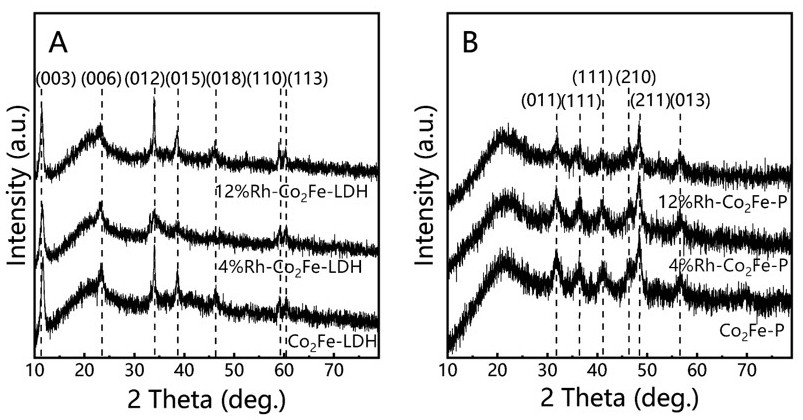

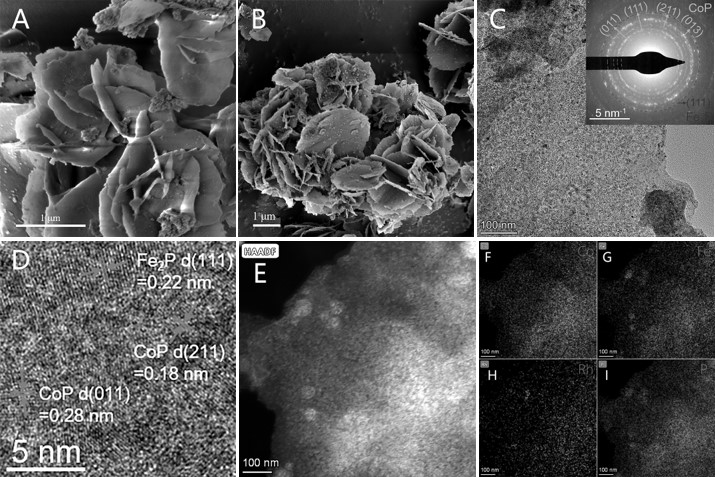

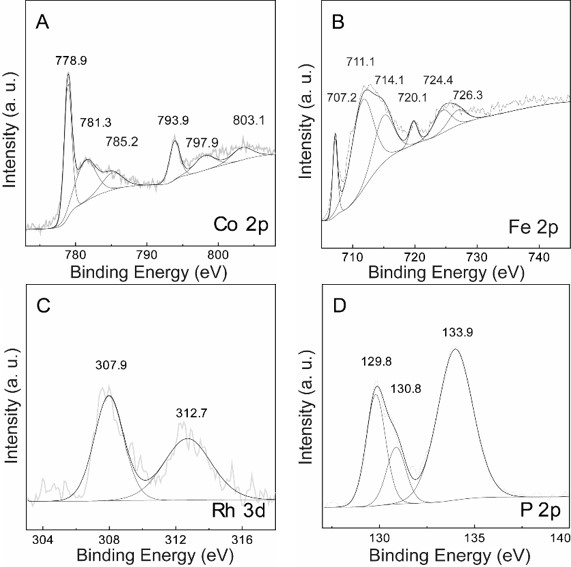

Preparation method of noble metal doped bimetallic phosphide catalyst for electrochemical complete water splitting

The invention discloses a preparation method of a noble metal doped bimetallic phosphide catalyst for electrochemical complete water splitting. Wherein the precious metal is rhodium, and the bimetallic phosphide is ferrocobalt phosphide. According to the preparation method, cobalt nitrate hexahydrate, iron nitrate nonahydrate, rhodium trichloride and urea are selected as raw materials, an ethylene glycol-assisted hydrothermal method is used for obtaining a rhodium-doped ferrocobalt double hydroxide precursor, then the rhodium-doped ferrocobalt double hydroxide precursor and sodium hypophosphite are annealed in a nitrogen atmosphere, and the petal-shaped rhodium-doped ferrocobalt phosphide nanometer material is obtained. The material can reach the current density of 10mA. Cm <-2 > only by the overpotential of 76mV in HER under an acid reaction condition. In 1 M KOH, when the current density reaches 10 mA. Cm <-2 >, the overpotentials of HER and OER are 48 mV and 303 mV respectively. When the Rh-doped Co2Fe-P composite material is used as a bifunctional electrode for overall water decomposition, the Rh-doped Co2Fe-P composite material can reach the current density of 10mA. Cm <-2 > in 1M KOH by only needing the low battery voltage of 1.54 V, and the current density is kept stable for not less than 30 hours. Meanwhile, the preparation method is simple and easy, the cost is low, the performance can be comparable with that of a commercial noble metal catalyst, and the application prospect is good.

Owner:EAST CHINA UNIV OF SCI & TECH

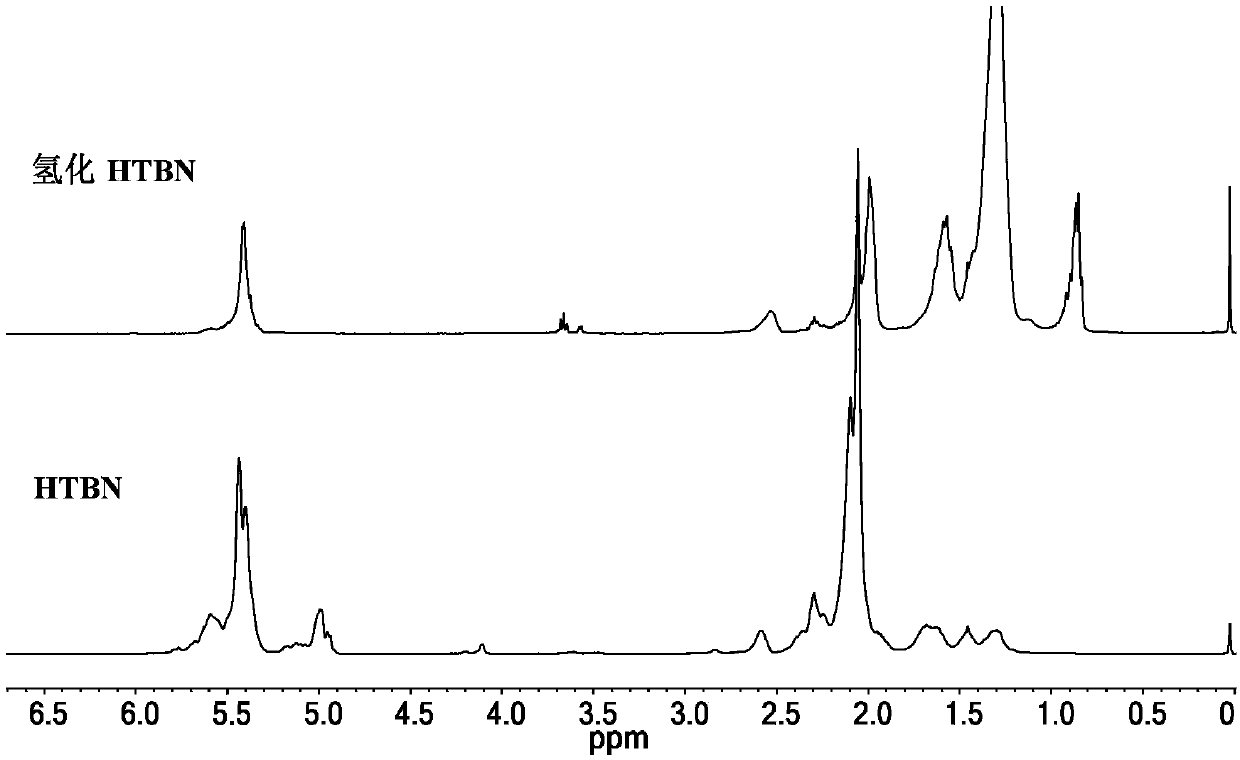

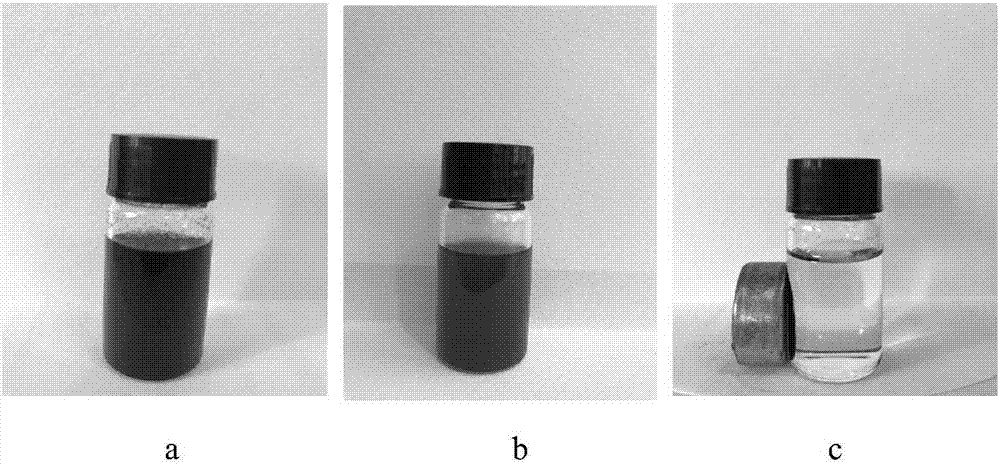

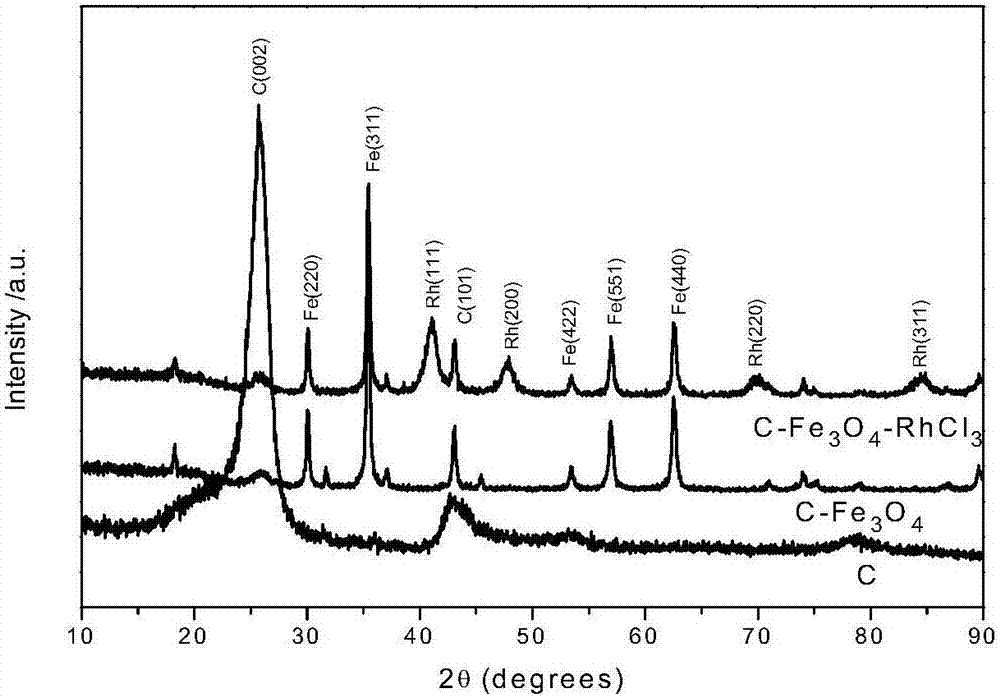

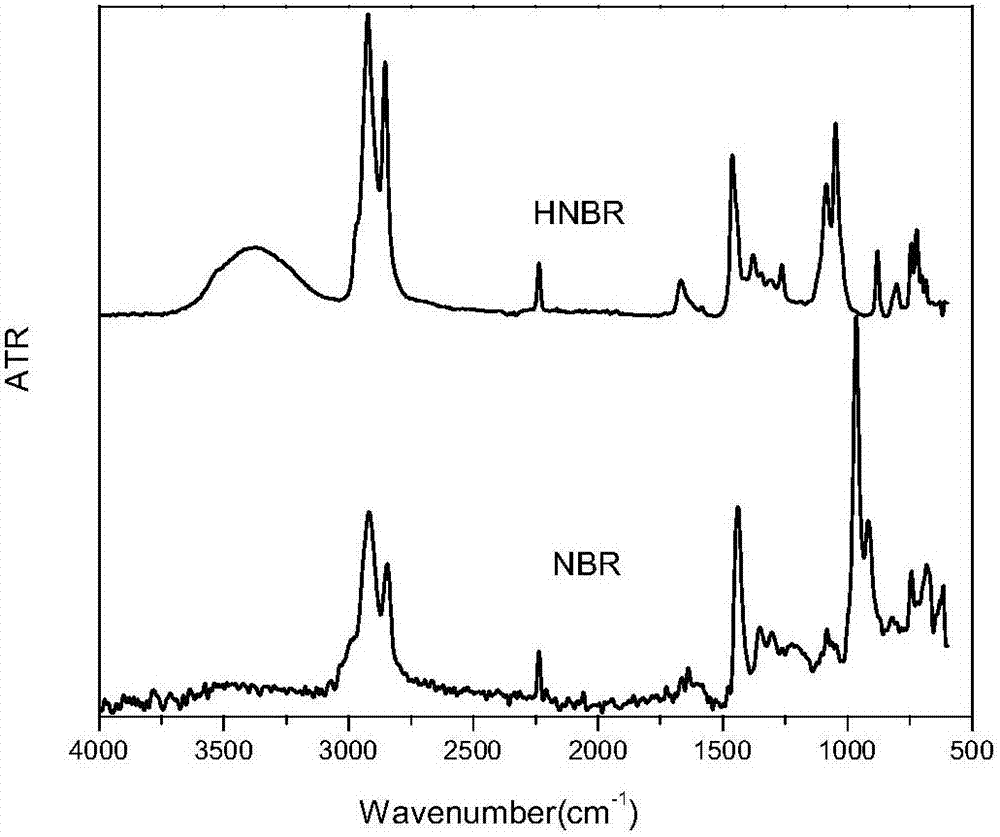

Preparation of magnetic carbon nanotube supported rhodium catalyst and application thereof in selective hydrogenation of NBR (nitrile butadiene rubber)

ActiveCN107051552AEasy to makeNon-toxicPhysical/chemical process catalystsChemical recyclingSodium acetateDouble bond

The invention discloses preparation of a magnetic carbon nanotube supported rhodium catalyst and application of the magnetic carbon nanotube supported rhodium catalyst in selective hydrogenation of NBR (nitrile butadiene rubber), wherein the preparation of the magnetic carbon nanotube supported rhodium catalyst comprises the following steps: putting perchloride iron, sodium acetate, carbon nanotubes and glycol in a reactor, carrying out a hydrothermal reaction after homogenizing, and then performing magnetic separation to remove unmagnetized carbon nanotubes after the reaction is accomplished, so as to obtain magnetic carbon nanotubes; dissolving rhodium trichloride in ethanol, adding the magnetic carbon nanotubes to react, then carrying out magnetic separation to obtain the magnetic carbon nanotube supported rhodium catalyst. A magnetic carbon nanotube carrier prepared by the application of the invention is used for supporting metal rhodium, and further used for study on hydrogenation of NBR. Experimental results show that the prepared supported catalyst has very high catalytic activity and good selectivity of double bonds, and the catalyst is magnetically recycled and simply processed after being hydrogenated, and is still very high in rehydrogenation efficiency.

Owner:ANHUI UNIVERSITY

Preparation method of acetylacetonatodicarbonyl rhodium

The invention discloses a preparation method of acetylacetonatodicarbonyl rhodium. The method comprises the following steps: (1) adding a defined amount of water in dimethylformamide; (2) dissolving trihydrate rhodium chloride in dimethylformamide, refluxing; adding acetylacetone in the mixture, refluxing again; (4) stopping heating to ensure that the reaction mixture is naturally cooled, pouring the mixture in deionized water, stirring; and (5) filtering the mixture, drying and recrystallizing. Compared with the prior art, the yield of rhodium can be increased to 95%, which brings a lot of economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high-purity acetylacetonatodicarbonyl rhodium through using rhodium trichloride

ActiveCN102976913AYield has no effectMeet the requirements of the indicatorsGroup 8/9/10/18 element organic compoundsPreparation of aldehyde/ketone chelatesEthylenediamineMetal impurities

The invention relates to a method for preparing high-purity acetylacetonatodicarbonyl rhodium through using rhodium trichloride. The method comprises the following steps: mixing rhodium trichloride containing metal impurities with N,N-dimethyl formamide and acetylacetone, heating to reaction completeness, cooling the obtained reaction solution to room temperature, adding deionized water, filtering the obtained precipitate, washing the precipitate to obtain crude acetylacetonatodicarbonyl rhodium, dissolving the crude acetylacetonatodicarbonyl rhodium in a sufficient amount of an organic solvent, washing the obtained organic phase by an aqueous solution of disodium ethylene diamine tetraacetate twice, and washing the organic phase by water once to obtain an acetylacetonatodicarbonyl rhodium solution. The method which adopts the acetylacetonatodicarbonyl rhodium containing the metal impurities as a reaction raw material enables the rhodium recovery process to be substantially shortened, so the production cost is reduced, and the economic benefit of the method is large.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Method for preparing rhodium trichloride hydrate by using silica gel-polyamine resin

ActiveCN104478008AMeet exchange requirementsSimplified processing stepsRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsHydration reactionSilica gel

The invention relates to a method for preparing rhodium trichloride hydrate by using silica gel-polyamine resin. The method comprises the following steps: adding water to dilute a rhodium acid digestion solution obtained after digestion of rhodium residues by concentrated sulfuric acid and nitric acid, adding a sodium chloride solid, and heating to reflux the obtained solution; allowing the solution to go through an exchange column filled with silica gel-polyamine resin; and sequentially eluting a small amount of sodium, iron, calcium, nickel and other metals residual in the column and adsorbed to the resin by using deionized water and 1-6mol / L of a hydrochloric acid solution, eluting rhodium adsorbed to the resin by using 6-12mol / L of 50-90DEG C hydrochloric acid, and evaporating the eluted chlororhodic acid solution to obtain the rhodium trichloride hydrate. In the rhodium acid digestion solution, the rhodium content is 1-10wt%, the nitrate content is 1-5wt%, and the sulfuric acid content is 30-85wt%; a molar ratio of sodium chloride to rhodium in the digestion solution is 3-15; and the silica gel-polyamine resin is water soluble polyurethane, and is combined to resin formed on the surface of a silica gel carrier in a covalent bond mode. The method for preparing rhodium trichloride hydrate from the rhodium acid digestion solution has the characteristics of high recovery efficiency, simple process, mild process conditions and the like.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com