Rhodium/nickel alloy nano-catalyst, preparation method and application thereof

A nano-catalyst, nickel alloy technology, applied in the field of nano-catalyst research, can solve the problems of no industrialization value, high cost, retention and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of catalyst:

[0025] Using rhodium trichloride and nickel acetate as raw materials, hydrazine hydrate as reducing agent, rhodium / nickel alloy nano catalysts are prepared in the presence of organic modifiers.

[0026] When the molar ratio of rhodium to nickel is 0.04:1, the rhodium / nickel alloy catalyst (Rh 0.04 Preparation of Ni): Weigh 0.2106g of RhCl 3 ·3H 2 O, 4.9768g of C 4 H 6 NiO 4 .4H 2 O and 0.5187g of 3-(aminopropyl)triethoxysilane (APTS) were dissolved in 50mL, 90mL, and 20mL of absolute ethanol after ultra-biodispersion, and the resulting RhCl 3 ·3H 2 O and C 4 H 6 NiO 4 .4H 2 The ethanol solution of O was mixed and then mixed with the ethanol solution of 3-(aminopropyl)triethoxysilane (APTS) at 50° C. for 20 min. Adjust the pH to 13 with 0.8mol / L NaOH ethanol solution, add 100mL of 0.75mol / L hydrazine hydrate absolute ethanol solution dropwise to the above reaction solution, react at 70℃ for 6h, the product will be repeated After alcohol washing ...

Embodiment 2

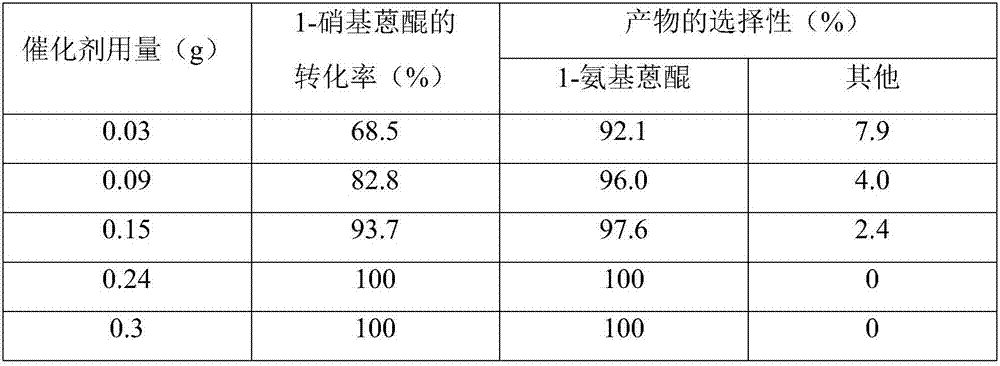

[0030] As in Example 1, only the amount of catalyst was changed to 0.03g, 0.09g, 0.15g, 0.24g, 0.3g, and the 1-nitroanthraquinone selective hydrogenation reaction was carried out. The resulting product selectivity and raw material conversion rate are shown in Table 1.

[0031] Table 1 shows that at 0.8MPa H 2 Under pressure, the reaction temperature is 130°C, and the reaction is kept for 6 hours. When the amount of catalyst is different, the rhodium / nickel alloy nano-catalyst can selectively catalyze the 1-nitroanthraquinone hydrogenation reaction product 1-aminoanthraquinone selectivity and raw material conversion rate According to the data analysis in Table 1, the amount of rhodium / nickel alloy nano-catalyst has an important influence on its catalytic activity for the selective hydrogenation of 1-nitroanthraquinone to prepare 1-aminoanthraquinone. When the amount of rhodium / nickel alloy nanocatalyst is 0.24g, under the experimental conditions, the conversion rate of 1-nitroanth...

Embodiment 3

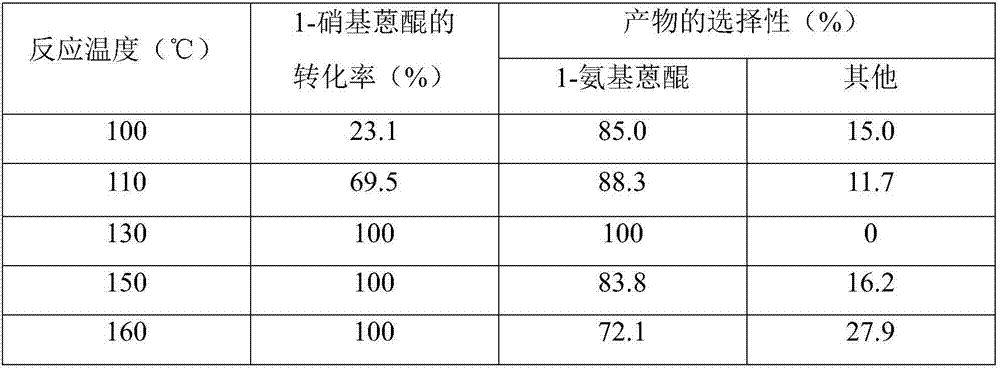

[0035] The same as in Example 1, only changing the temperature of the reaction kettle to: 100°C, 110°C, 130°C, 150°C, and 160°C, for selective hydrogenation of 1-nitroanthraquinone. The resulting product selectivity and raw material conversion rate are shown in Table 2.

[0036] Table 2 shows that at 0.8MPa H 2 Under pressure, when the amount of catalyst is 0.24g, the rhodium / nickel alloy nano-catalyst can selectively catalyze the selectivity of 1-nitroanthraquinone hydrogenation reaction product 1-aminoanthraquinone and the conversion of raw materials under different reaction temperature and heat preservation for 6 hours. According to the data analysis in Table 2, under the experimental conditions, the reaction temperature has an important influence on the catalytic activity of the rhodium / nickel alloy nano-catalyst to selectively catalyze the hydrogenation of 1-nitroanthraquinone to prepare 1-aminoanthraquinone. When the reaction temperature is 130°C, the conversion rate of 1-n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com