Preparing-1-pentanal from mixed solvent ion liquid of tetrafluorborate methyl buty I imidazole salt/water

A technology of methyl butyl imidazolium tetrafluoroborate and ionic liquid, which is applied in the field of organic compound preparation, can solve the problems of poor selectivity, shorten the reaction time, achieve recycling, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

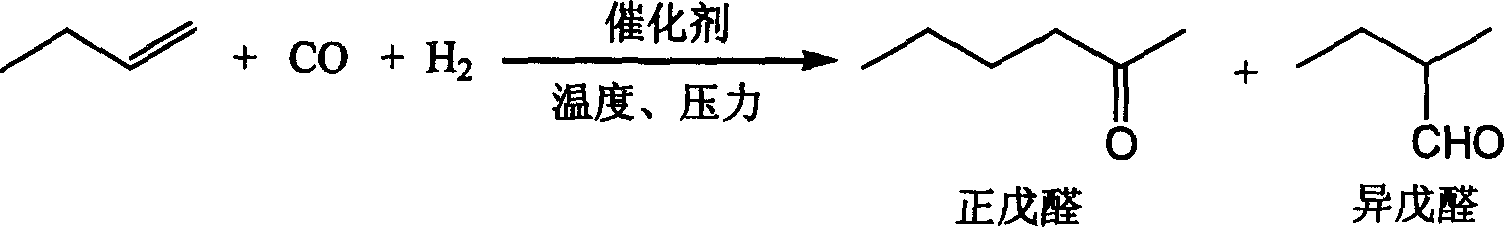

Problems solved by technology

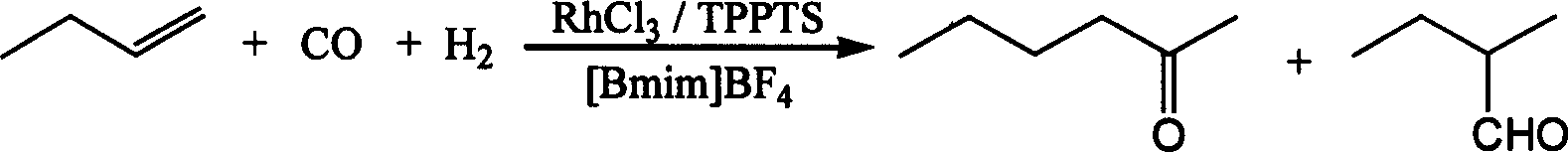

Method used

Image

Examples

Embodiment 1

[0023] 1.0g of rhodium trichloride, 220g of sodium m-triphenylphosphinetrisulfonate, 300g of tetrafluoroborate methylbutylimidazolium salt, 100g of water and 250g of 1-butene were put into the autoclave in sequence, and CO and H 2 The mixed gas with a volume ratio of 1:1 was subjected to a hydroformylation reaction at 60 atmospheres, 80°C and strong stirring for 30 hours, cooling, deflation, gravity settlement, and liquid separation to obtain the product with a yield of 98%. 1-pentanal content 92%. The separated ionic liquid / water catalytic system is recycled.

Embodiment 2

[0025] Put 1.0g of rhodium trichloride, 220g of sodium m-triphenylphosphinetrisulfonate, 300g of methylbutylimidazolium tetrafluoroborate, 100g of water and 250g of 1-butene into the autoclave in sequence, and introduce CO and H 2 The mixed gas with a volume ratio of 1:1 was subjected to hydroformylation reaction at 60 atmospheres, 80°C and strong stirring for 20 hours, cooling, deflation, gravity settlement, and liquid separation to obtain the product with a yield of 80%. 1-pentanal content 92%. The separated ionic liquid / water catalytic system is recycled.

Embodiment 3

[0027] 1.0 g of rhodium trichloride, 200 g of sodium m-triphenylphosphine trisulfonate, 300 g of tetrafluoroborate methylbutylimidazolium salt, 100 g of water and 250 g of 1-butene were put into the autoclave in sequence, and CO and H 2 The mixed gas with a volume ratio of 1:1 was subjected to hydroformylation reaction at 60 atmospheres, 80°C and strong stirring for 30 hours, cooling, deflation, gravity settlement, and liquid separation to obtain the product with a yield of 90%. 1-pentanal content 86%. The separated ionic liquid / water catalytic system is recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com